Why Is Copper No Longer Used For Busbars

A lower density means less weight, making the aluminum conductors cheaper than a copper busbar. The higher strength and durability make it more efficient for power transmission.

It has a more efficient design which makes it better for electrical applications in the home or office setting. Higher densities also offer improved performance when compared to other materials when used as an energy conductor.

You'll Learn About

Why Is Copper No Longer Used For Busbars?

A lower density means less weight, making aluminum cheaper to produce. Aluminum busbars are more efficient for power transmission than copper ones because they have a higher strength and durability.

The higher strength and durability of copper also make it a better choice for cables that will be subjected to heavy use or pressure over time. While there is some cost associated with using a high-density cable, it can offer significant benefits in terms of efficiency and performance

Lower Density Means Less Weight

Aluminum busbars are often used for their low weight and high conductivity, but this material is no longer in use due to its lower density. A higher-density copper will result in a heavier busbar and may not be as efficient when transferring electricity.

Good coatings can help improve the electrical conductivity of copper without adding extra weight or thickness, which is an important consideration when selecting a busbar material. There are other materials that offer similar benefits with less weight and impact on efficiency, so it’s important to choose the right one for your application.

When choosing a busbar material, consider how much weight you’re willing to carry and whether increased efficiency is worth the added burden

Cheaper Than Copper Busbar

Copper busbars are becoming less common due to their high cost. Alternatives such as aluminum are often cheaper and more durable. The popularity of renewable energy sources is also a factor in the decline of copper busbars.

Busbar construction has changed over the years, making them incompatible with older equipment and wiring systems. Maintenance can be difficult with copper buses, requiring regular cleaning and lubrication.

Higher Strength & Durability

Copper is no longer used for busbars because of its high strength and durability. Busbars are made from a variety of materials, but copper offers the best performance and reliability.

Other materials, such as aluminum, offer similar benefits with less weight and cost. You can still find busbars made from copper in some situations. However, they’re becoming rarer due to their performance advantages over other materials.

When selecting a busbar material, be sure to take into account your specific needs and requirements.

More Efficient For Power Transmission

Copper has been used for busbars in the past because it is a good conductor of electricity. However, copper is not as efficient when transmitting power as newer materials are.

Busbars made from other materials are more efficient and can save energy over time. Copper doesn’t corrode over time and damage equipment that uses power transmission lines. Moving to a more efficient material can help reduce costs associated with using power while protecting infrastructure

Are busbars made of copper?

Yes, busbars are usually made of copper. Copper is a very good conductor of electricity and it does not corrode over time as other metals can. This makes it a great choice for electrical connections in homes, households, offices, and even rocket.

Copper is a metal that is more resistant to rust and corrosion than other metals, making it beneficial for busbars. Busbars are made of copper and this material is often used in the production of electrical equipment such as transformers and capacitors.

Copper also has a high electrical conductivity which makes it ideal for use in appliances like televisions, radios, microwaves, and refrigerators. Copper is beneficial for your appliances because it can withstand higher temperatures than other materials while still providing efficient performance. This makes it a popular choice among manufacturers.

Copper is commonly used in the production of electrical equipment because its strength allows it to handle large amounts of current. Also, it doesn’t break down easily or causing interference with other devices nearby – two important qualities when producing electronic components.

Although not always necessary, using copper busbars can be advantageous for both your hardware and your appliance needs due to their resistance to corrosion and overall durability.

Which is better aluminum or copper bus bar?

There is no definitive answer when it comes to which type of bus bar is better – aluminum or copper. Ultimately, the best choice depends on your specific needs and preferences.

The two most common materials used for bus bars are aluminum and copper. Both of these metals have their own advantages and disadvantages when it comes to electrical ratings, volume comparisons, material properties, installation, and more.

Aluminum has a higher electrical rating than copper, but both metal buses can handle a large amount of electricity before they start to fail. Copper is much harder than aluminum so it will not cause as much damage if it is bent or snapped while wiring your systems.

However, copper also conducts heat better than aluminum which can lead to problems with overheating in high-performance engines. When comparing temperature ratings between the two metals, aluminum usually wins hands down – even under extreme conditions like direct sunlight exposure or automotive engine temperatures.

Installation is another factor that should be considered when making a decision about which bus bar material to use in your system’s wiring system. Both options require some level of expertise and properly fitting hardware in order for them to work correctly.

What is copper busbar used for?

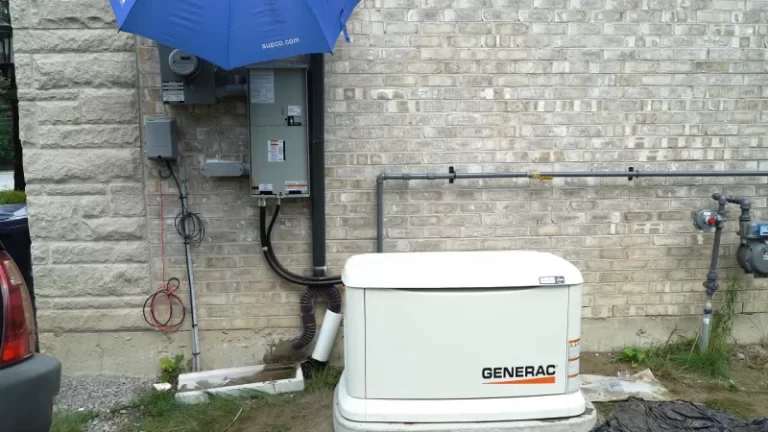

Copper busbars are used in electric power distribution to connect high voltage equipment at electrical switchyards and low voltage equipment in battery banks.

They can protect against shocks and sparks when a fault occurs, making them fire-resistant. Copper busbars are also used in connection with certain types of high-voltage equipment, such as electric switches or batteries.

What metal are busbars made of?

Busbars are produced in various shapes and made of different metals, such as copper, brass, or aluminum. Their shape allows for more efficient dissipation of heat, which is beneficial in applications like electric grids and power plants.

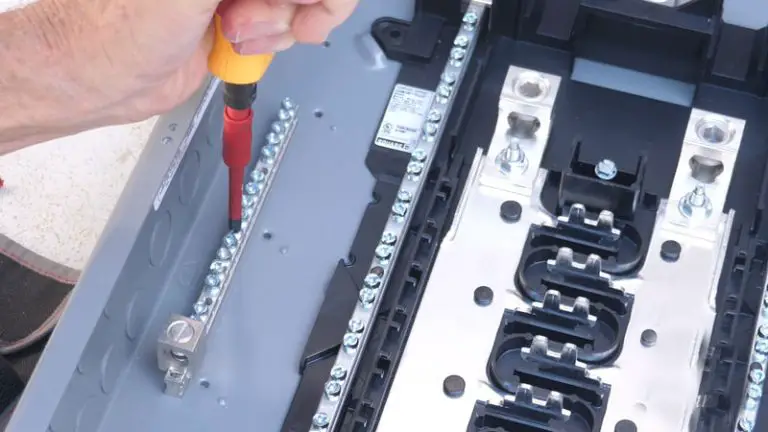

Flat strip busbars have a high surface area to cross-sectional area ratio, making them ideal for applications that require a lot of dissipated heat (like industrial processes). Finally, because they are flat strips, busbars can be easily mounted on boards or other surfaces using screws or rivets.

Can aluminum be used as a busbar?

Aluminum can be used as a busbar, but it’s not recommended for this purpose. The metal is too soft and can easily bend or crack under the weight of a power cable.

Instead, use a cupper to use as a busbar.

Aluminum is light and easy to install

Aluminum busbars are a great option for use in electric power distribution systems because they are lightweight and easy to install.

They can be customized with extruded profiles that make them securely placed, slide or dovetail into position quickly and easily, and require only one operator to complete the installation process.

Customizability makes them secure

The customizable nature of aluminum busbars means that they can be secured in place using various techniques such as screwing or bolting.

This ensures that your system is safe from damage caused by accidental knocks or movement.

Ease of installation makes them a popular choice

Installation times for aluminum busbars are usually much shorter than those for other types of busbar kits, which makes them an ideal choice if you need a quick turnaround time on your project.

What are copper bus bars coated in?

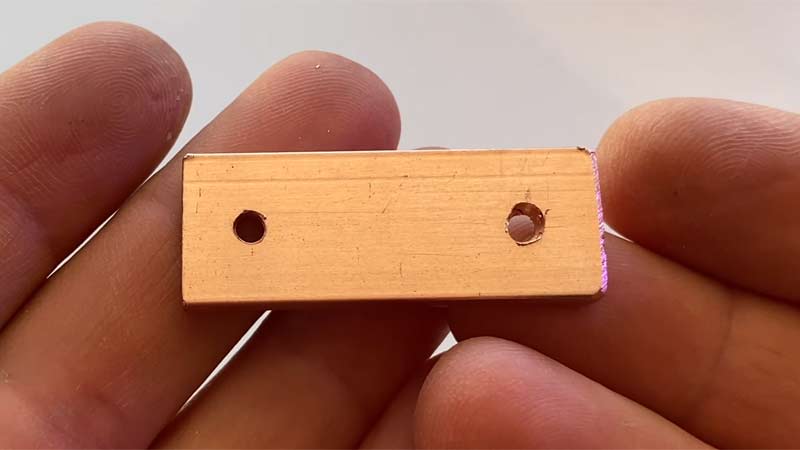

Copper bus bars are coated with tin to provide excellent corrosion resistance. Parts are soldered together with a good connection for power electronics and allow for an exceptional appearance.

Solderability is superior for power electronics, resulting in a well-connected joint that appears flawless. Copper’s natural properties of being a great conductor make it the perfect material for powering devices

Can brass be used as a bus bar?

Brass is a combination of copper and other metals, making it sturdy and less malleable than many other metals. It has good conductivity, which makes it a great choice for bus bars.

While brass is less common to use as a bus bar, it makes an excellent option when selected carefully. Be sure to measure the space you will be using your bus bar in before selecting brass. Otherwise, you may end up with an unnecessarily expensive purchase.

Brasses are available in both round and hexagonal shapes, so there’s no need to worry about getting one that isn’t compatible with your project or style.

Kerdi Shower Pan With Cement Board Walls

Why is brass much harder than copper?

Brass is much harder than copper because of the way it is made. Brass is a metal alloy, which means that it contains both copper and other metals. The main difference between brass and copper is that brass has more zinc (zinc makes brass hard).

Brass is Made of Distorted Layers of Atoms

Smaller atoms make brass stronger than copper or zinc alone. Because brass consists of smaller, distorted atoms, it is much harder than either of those materials on its own. This makes brass a more durable material and helps to prevent strains from happening easily.

Strains happen more easily in brass because regular lattice structure isn’t as accurate

Due to the way that brass is made, strains will occur at different points along the metal’s surface more often than they would with copper or zinc alloyed metals. As a result, repairs are usually required less frequently for brasses but can still be expensive when compared to other types of metals.

Brass Cost More Than Copper and Zinc

Brass costs more than both copper and zinc due to the additional labor needed during production. However, this extra cost may be worth it if you’re looking for a strong and durable material that won’t require as many repairs over time.

Brass Can Be Tumbled Like Copper Or Zinc To Reshape It

Brass is usually softer than copper or zinc. Therefore, brass will usually be more susceptible to having its shape altered by the tumbler. Copper or zinc will usually be reshaped more easily, and so the tumbler may be used for these metals more often than it will be used for brass.

To Recap

Copper has been gradually replaced by other materials in busbars for a variety of reasons, including cost-effective manufacturing and improved reliability.

While a copper still has its benefits, it is no longer the only material that can be used in busbars.

Also Read – GE Cafe Refrigerator Ice Maker Problems and Solutions