Too Much Oil In Snowblower? The Hidden Engine Dangers & Your Fast Fix

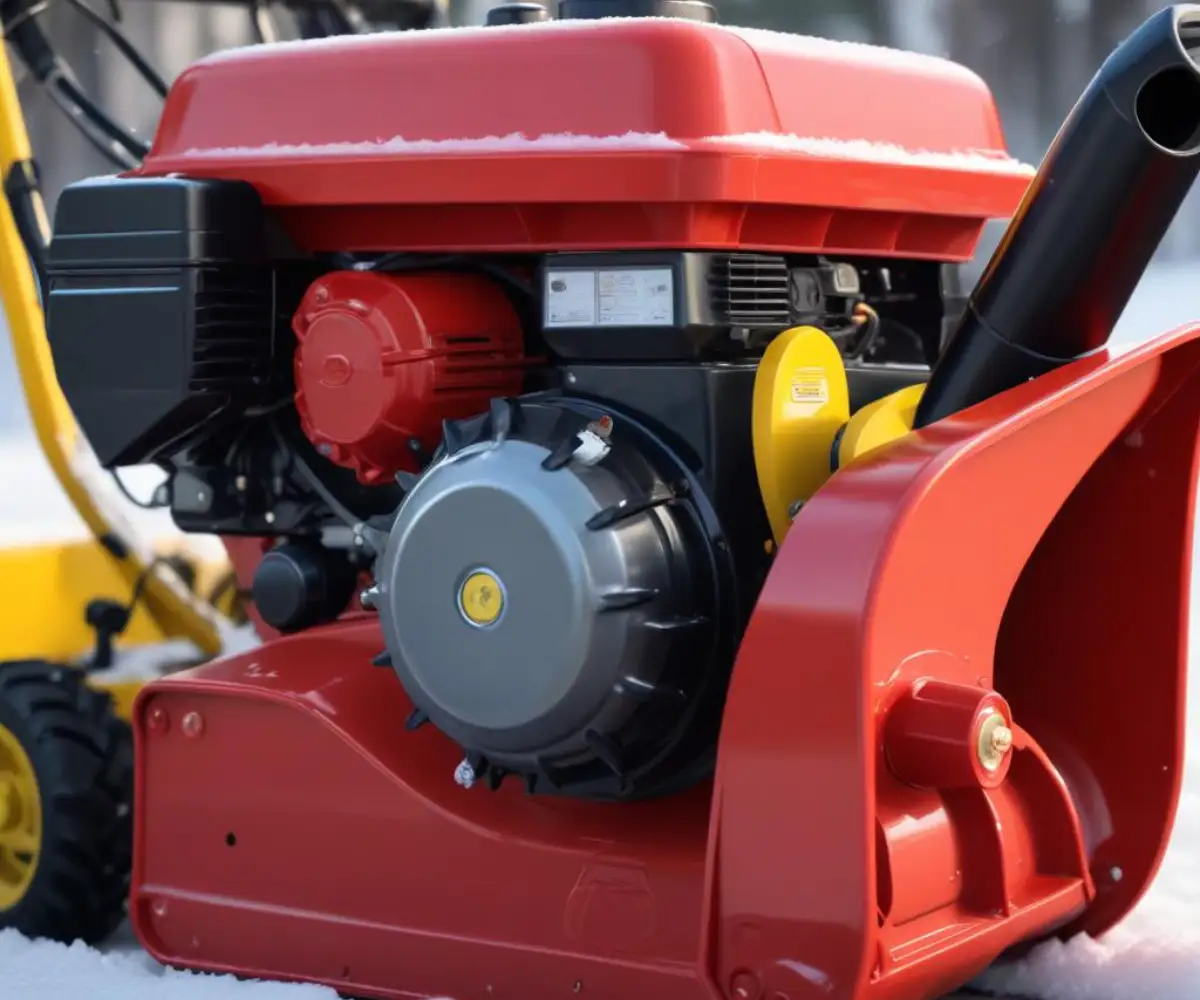

A common belief holds that keeping an engine topped off with oil is the pinnacle of responsible maintenance. While running an engine low on oil is certainly a recipe for disaster, its opposite—overfilling with oil—is a more insidious problem that can cause significant and costly damage. For snowblower owners, this simple mistake made during a seasonal oil change can lead to a cascade of mechanical failures right when the machine is needed most.

Understanding the consequences of too much oil is the first step toward prevention and timely correction. This guide will explore the clear warning signs of an overfilled snowblower, delve into the internal mechanics of what goes wrong, and provide a clear, step-by-step solution to fix the problem and safeguard your engine for future winters.

You'll Learn About

Decoding the Danger Signs: Symptoms of an Overfilled Snowblower

When a snowblower’s crankcase has too much oil, the engine will quickly protest. The symptoms can range from subtle performance dips to dramatic, unmistakable warnings. Recognizing these signs early is crucial to preventing permanent damage.

White or Blue Smoke from the Exhaust

Perhaps the most alarming and common symptom is thick white or bluish smoke billowing from the exhaust. This occurs because the excess oil gets churned into a foam and forced into the cylinder through the crankcase breather tube. Once in the combustion chamber, the oil burns along with the fuel, producing dense, discolored smoke.

Engine Struggling to Start or Not Starting at All

An overfilled engine can be difficult or impossible to start. The excess oil can foul the spark plug, preventing it from creating the necessary spark for ignition. In severe cases, enough oil can enter the cylinder to cause hydrolock—a condition where the piston cannot complete its compression stroke because the liquid oil won’t compress, potentially bending connecting rods or causing catastrophic failure. If you find your machine won’t turn over, it may not just be an oil issue; sometimes, what seems like a fuel or oil problem can be related to the electrical system, and understanding why a Craftsman snowblower electric start is not working could offer clues for other brands as well.

Oil Leaks and Seeping Gaskets

Your engine is a sealed system designed to operate under specific internal pressures. Too much oil dramatically increases this pressure, forcing it to find the weakest points of escape. This often results in oil seeping past gaskets and seals, leading to noticeable drips and leaks on your garage floor.

Reduced Engine Power or Stalling

When the crankshaft is forced to slap through a deep pool of excess oil, it creates significant drag, robbing the engine of power. The oil also gets aerated into a froth, which does not lubricate properly. This combination of resistance and poor lubrication can cause the engine to bog down, run rough, or stall completely, especially under the load of heavy snow.

The Smell of Burning Oil

Distinct from the smell of exhaust fumes, you may notice a pungent, acrid smell of burning oil. This can happen when oil forced out of seals drips onto the hot engine block or muffler, burning off externally. It’s a clear sign that oil is escaping the crankcase where it doesn’t belong.

Oil in the Air Filter or Carburetor

The crankcase ventilation system is designed to release pressure, but when overwhelmed by excess oil, it can push oil vapor and droplets up the breather tube and directly into the air filter housing. A saturated, oil-soaked air filter is a classic sign of overfilling. This oil can then be drawn into the carburetor, disrupting the air-fuel mixture and causing poor engine performance.

To help you quickly diagnose the issue, the table below summarizes the key symptoms, their underlying causes, and the potential severity of the problem.

| Symptom | Probable Cause | Severity Level |

|---|---|---|

| White/Blue smoke from exhaust | Oil entering the combustion chamber and burning | Moderate |

| Engine won’t start or is hard to start | Oil-fouled spark plug or potential hydrolock | Moderate to Severe |

| Visible oil leaks | Excessive crankcase pressure forcing oil past seals/gaskets | Moderate |

| Loss of power or engine stalling | Crankshaft drag and oil aeration (foaming) | Moderate |

| Oil in the air filter housing | Oil being forced through the crankcase breather tube | Moderate |

| Engine is seized (pull cord won’t move) | Severe hydrolock from oil filling the cylinder | Severe |

The Science of Failure: What Happens Inside Your Engine with Excess Oil?

To truly appreciate the danger of overfilling, it’s important to understand the mechanical chaos it creates inside the engine. Most snowblower engines use a “splash lubrication” system, which is highly effective but particularly vulnerable to excess oil.

Crankshaft Drag and Aeration: The Foamy Killer

In a splash lubrication system, dippers or “slingers” on the rotating crankshaft are designed to just skim the surface of the oil reservoir. This action splashes a lubricating mist onto all the moving parts. When the oil level is too high, the crankshaft and connecting rod don’t skim; they submerge and violently churn the oil.

This churning process, known as aeration, whips the oil into a frothy, bubbly foam. Aerated oil is a catastrophic failure for lubrication. The air bubbles create pockets where there is no protective oil film, leading to metal-on-metal contact, extreme friction, and overheating of critical components like bearings and cylinder walls.

Catastrophic Pressure Build-Up

Liquids do not compress. As the piston moves and the crankshaft rotates, the space inside the crankcase changes. This system is designed to manage the resulting pressure changes with a specific volume of air and oil vapor. When you add too much oil, you remove the air volume needed to buffer these pressure fluctuations.

The result is a dramatic spike in internal crankcase pressure. This pressure acts like a relentless force, pushing outward in all directions. The engine’s weakest points—the crankshaft seals and paper gaskets—are the first to fail, creating leaks that can be difficult and expensive to repair.

The Path to Hydrolock

The most destructive outcome of overfilling is hydrolock. As extreme pressure builds in the crankcase, the foamed oil is aggressively forced up the breather tube into the air intake and past the piston rings into the combustion chamber. If enough liquid oil accumulates in the cylinder, the piston, on its upward compression stroke, will slam into this incompressible fluid.

The force is immense and has nowhere to go. This can instantly stop the engine and may result in a bent connecting rod, a cracked piston, or other severe internal damage. An engine that has been hydrolocked often requires a complete rebuild or replacement.

The Ultimate Fix: How to Safely Remove Excess Oil from Your Snowblower

If you’ve identified the symptoms of an overfilled snowblower, the good news is that if you haven’t run the engine for long, the fix is straightforward. The goal is simply to remove the excess oil to bring the level back within the manufacturer’s recommended range.

Step 1: Preparation and Safety First

Before starting, move your snowblower to a level surface to ensure an accurate oil reading. Gather your tools: a socket wrench or adjustable wrench that fits your drain plug, a suitable oil drain pan, and plenty of clean rags or paper towels. For safety, always disconnect the spark plug wire to prevent any chance of an accidental engine start.

Step 2: Identify the Correct Draining Method for Your Machine

There are three primary ways to remove excess oil. Your choice will depend on your snowblower’s design and the tools you have available.

- Method A: Using the Drain Plug (The Best Way). This is the most common and effective method. The drain plug is typically a bolt located at the base of the engine, often on the side or rear.

- Method B: Using an Oil Extractor Pump (The Clean Way). An oil or fluid extractor is a simple hand pump with a tube that you insert into the dipstick opening to siphon oil out. This is a mess-free alternative if your drain plug is difficult to access.

- Method C: The Tipping Method (The Last Resort). If you have no other option, you can carefully tip the snowblower to pour oil out of the fill hole. Be extremely careful to tip it so that the carburetor and air filter are facing up to prevent fuel spillage and further oil contamination of these components.

Step 3: Draining the Excess

Your goal is to remove only the excess oil, not all of it. If using the drain plug, slightly loosen it until oil begins to drip out slowly. Let a few ounces drain into the pan, then tighten the plug. It’s better to drain too little and re-check than to drain too much.

If using an extractor pump, siphon out a small amount of oil. If tipping the machine, do so very carefully and briefly. The key is to work in small increments.

Step 4: The Crucial Final Check

After removing some oil, let the machine sit for a minute to allow the remaining oil to settle. Clean the dipstick thoroughly with a rag, reinsert it fully (screw it in if it’s a threaded type), and then remove it to check the level. The oil should be between the “ADD” and “FULL” marks. Repeat the draining and checking process until the level is correct.

After the Fix: What to Do If You Already Ran the Engine

If you ran the snowblower long enough for it to smoke or stall, you have a few more steps to take after correcting the oil level. Oil has likely contaminated other parts of the engine system.

Inspect and Clean the Spark Plug

Remove the spark plug and inspect it. It will likely be coated with black, oily residue. You can clean it carefully with a wire brush and brake cleaner, but replacing it with a new one is an inexpensive and highly recommended step to ensure a strong spark.

Check and Clean the Air Filter

Open the air filter cover and remove the filter. If it is a paper element and is soaked with oil, it must be replaced. An oil-saturated filter cannot be cleaned and will severely restrict airflow to the engine. If it is a foam filter, it can often be washed with soap and water, dried completely, and then re-oiled with proper foam filter oil.

Look for Lasting Damage

After correcting the oil level and cleaning the plug and filter, start the engine. It may still smoke for a few minutes as it burns off residual oil in the exhaust system. If smoking persists or the engine continues to run poorly, you may have sustained gasket damage. Keep an eye out for new leaks over the next few uses. Persistent running issues could also point to problems beyond the oil system; for example, power loss symptoms could be related to a slipping belt, making it wise to know the Ariens snowblower belt tensioner spring location for a thorough inspection.

Prevention is Key: Best Practices for Future Oil Changes

The best way to deal with an overfilled snowblower is to prevent it from happening in the first place. Adopting a few simple habits during maintenance will ensure your engine is always filled to the perfect level.

Know Your Engine’s Oil Capacity

Before you even open a bottle of oil, consult your owner’s manual to confirm the exact oil capacity of your engine. Different models hold different amounts, and assuming is a common cause of overfilling. For example, a vintage machine like a Toro S120 Snowblower has very different requirements than a modern, larger-displacement engine.

The “Add and Check” Method

Never pour the entire specified amount of oil into the engine at once. After draining the old oil, start by adding about 75% of the recommended capacity. Wait a minute for the oil to settle into the crankcase, then check the level with the dipstick. Continue adding small amounts of oil, checking the level after each addition, until you reach the full mark.

The Importance of a Level Surface

This simple detail is one of the most critical. Always perform oil changes and level checks on flat, level ground. Checking the oil on an incline will give you a false reading, leading you to either underfill or overfill the engine. An incline of just a few degrees can significantly alter the reading on the dipstick.

Conclusion: Protecting Your Investment for Winters to Come

Overfilling your snowblower with oil is a common but potentially severe mistake. It transforms a vital lubricant into a destructive force, causing everything from smoking and power loss to blown seals and catastrophic engine seizure. By learning to recognize the symptoms, understanding the internal mechanics of the problem, and following a methodical approach to both fixing the issue and preventing it in the future, you can protect your equipment.

Proper maintenance is about precision, not just diligence. Taking the extra minute to check your manual, pour oil slowly, and verify the level on a flat surface is the best insurance against costly repairs and ensures your snowblower will be ready and reliable when the first storm hits.