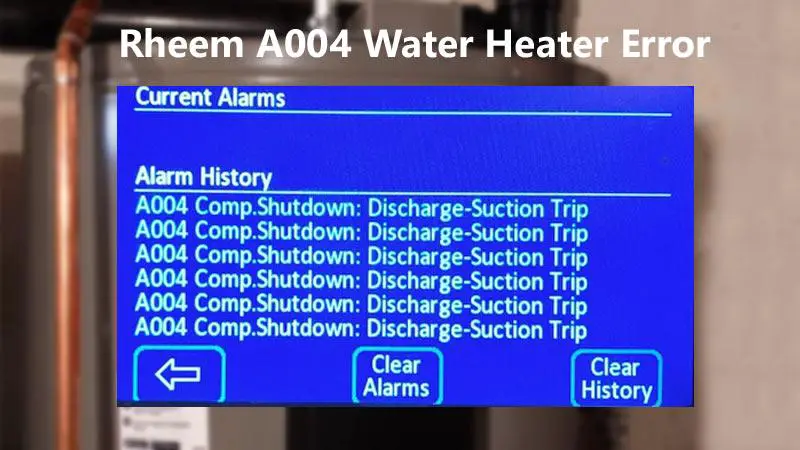

Rheem A004 Water Heater Error – Causes and Fixes

Investing in a water heater is essential for homes. It plays a significant role in regulating temperatures. However, it generally requires maintenance to remain effective. Properly heating the water can save energy costs. Moreover, it sustains your system’s condition.

It’s important to learn about the simple replacement of these systems. Calling professionals will cost more money. Not maintaining this valuable investment may result in damaging consequences that could have been avoided easily.

To avoid such risks, Rheem suggests replacing your old water heater once its service life ends. Be mindful of preserving your home’s cooling and heating systems. Regularly check and take care of them properly!

You'll Learn About

Why is Rheem Water Heater Showing an A004 Error?

When hot water is turned on, the heater display should show the A004 error. This means the compressor isn’t running, and the elements aren’t energized. No water is delivered since it’s an internal issue shown during shut-off.

The A004 error is displayed on the heater display panel when hot water is turned on. This indicates an internal issue where water cannot be delivered to the elements. The compressor isn’t running, and there’s a lack of energy in these components. The display also shows this during a shut-off period, implying no supply for warm liquid. The A004 error can be caused by several things, including:

- Malfunction of the compressor motor, hoses, or other components.

- A broken or disconnected electrical connection.

- A broken or disconnected water valve, orifice, or pipe.

1. Compressor Malfunction

Elements are the default heating source for a few reasons. Water flow issues often cause malfunctions. The control board and clogged filters frequently cause problems. Reset any thermostats you have in place.

If there is a blockage, hoses can stop water from flowing correctly. Running your heater will help determine this issue. Disconnecting the supply line and drain hose enables checking of the water’s movement. Ensure all flows fine.

Likewise, do precisely that if examining how well your control board operates. Ensure no obstruction is present already identified. Finally, test elements once sure that none of these issues caused other troubles.

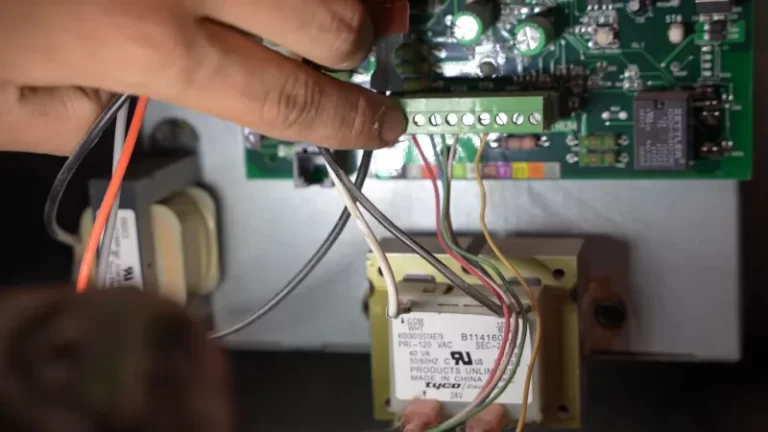

2. Disconnected Electrical Connection

The water heater’s heart, the compressor motor, heats and cools contracts with metal. It needs a voltage connection to heat water. It can malfunction if other connections break or disconnect from it. A broken or disconnected electrical connection of the compressor or other components can cause the compressor motor to fail.

To test for bad connections, remove wires connected to the compressor one by one. Check each using a multimeter. Should you find a short circuitry problem causing malfunctions, replace any faulty parts like fuses or circuit boards entirely. Purchase another compressor motor if necessary!

3. Broken or Disconnected Water Valve

The Rheem A004 water heater needs proper pressure to function. Here are some things you should do:

- Low pressure causes the error code on the control and diagnostic panels.

- Check if the valve has a disconnection or damage. It is fixable.

- Inadequate valve size may also interfere with the appropriate pressure supply.

- Disconnected hoses can result in decreased water flow for heating purposes.

- To avoid this, reconnect and test hoses behind the tank. Ensure they meet requirements.

If low pressure persists even after all troubleshooting mechanisms are used, replace the faulty valves. This is a guaranteed way of fixing your system. Seek further help from the home improvement store service department if needed.

4. Blown Fuse or Tripped Circuit of Water Heater

If your water heater makes loud noises, a blown fuse or tripped circuit is an easy fix. Check if more than one element was affected.

To test for a short, check the element and replace it if needed. Order from the manufacturer. For blown fuses, simply replace them unless you find another issue. Reconnect wires after replacing fuses.

The electrical parts inside circuits can be easily replaced with single trips only. Multiple trips require complete replacement of the whole circuit in most cases.

The circuit of the water heater has electrical parts inside. It’s easy to replace if it only has one trip. If you find the circuit has multiple trips, you’ll need to replace the whole circuit.

Always ensure to follow the manufacturer’s guidelines when making any replacements or repairs.

5. Control Board Malfunction

It’s not easy for most homeowners to repair a malfunctioned control board inside the system. A skilled technician is required in this scenario.

To start with any repair, check if the water heater is operating without issues. Additionally, remove the cover and inspect whether all parts such as lights or fans are functioning properly. If you’ve placed a thermostat, ensure it’s disconnected before starting troubleshooting steps. Use multimeters on each part while turning them on one-by-one.

Replacing a broken control board involves unplugging wires attached to it. Analyze their connection through testing mechanisms like multimeters or voltage testers. Replace what needs fixing once everything indicates that your device works again!

How Long Should a Rheem Water Heater Last?

Water heaters need to be serviced every 5 years so that they can last longer. Rheem water heaters should also have this maintenance done. Tankless and tank configuration ones come with different care. This means you will have them for way more time if properly attended.

15 years is the maximum life span of these models. Hence, you must replace your unit after that period or prepare yourself accordingly. A well-functioning heater from day one usually lasts at least five years in a row before giving any issue.

It’s not necessary whether an old model was adequately built with good parts. It could still wear down like other gadgets over time regardless of quality factors considered during production.

Knowing its age would help understand how much further it may push without breaking down unexpectedly. To know when exactly there might happen leakage requiring replacement because everything wears out eventually!

How to Fix the Rheem A004 Water Heater Error?

Fixing the error code isn’t so hard. You have to make sure the motor is working correctly. Ensure the filter is clean and the other components are okay.

Step 1: Check the Fan and Compressor

The fan is key for water heater and heat pump function. Without it, they malfunction. If the internal temperature of the unit becomes too high or if there are performance issues with the heat pump, check to ensure that its fan is operational.

Relay diagnostics require a 60V reading switch to ground. Also, test whether compressor activation causes operation in your system’s component parts. Lack of action by other components may mean trouble either sourcing power supply or due to an issue in relay connection.

Although uncommonly needed, repair service exists only rarely for those interested enough. When something goes wrong, invariably related control board correction work needs completing under warranty protection where applicable. This should fix all concerns about functionality right away!

Should systems continue working but still return nonfunction from operating checks (fan not running + no compressor), let Rheem know immediately. This ensures prompt delivery replacement hot water heaters before situations grow dire unnecessarily longer!

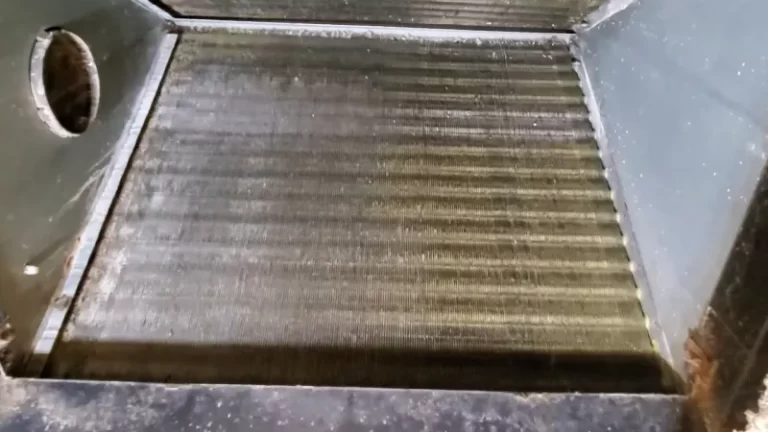

Step 2: Clean the Filter Screen

To resolve water heater error codes, inspect the filter screen on the control panel for blockages or dirt. If you see any issues, use compressed air to blow off debris from the bottom of your unit.

If after tackling these problems persist still, then check if there is a leak in your inlet causing this issue. Ensure that your filter screen doesn’t have dust build-up and is clean. Spray with water until fully cleared out to remove an error code.

In case you see other accompanying issues like poor airflow because of a dirty filter, lay it down flat before hosing away excess grits. This will make spotting remaining grime easier! The fan may not be working yet, but try turning on heat pumps once done clearing everything up. This will confirm proper functioning afterwards!

If confirmed faulty, purchasing another part should fix all errors instantly without further delay. Nothing else could cause such symptoms except perhaps internal hardware malfunctioning (which are rare). Finally, always do regular checks every now and then even when things seem okay as prevention!

Cleaning water heater screens is different from chimney cleaning, so be careful.

Step 3: Check for the Signs of a Refrigerant Leak

There might be a leak in the Rheem A004 water heater. If you spot any signs of leakage, you have an issue to deal with. You can try checking for the leaks by sucking refrigerant.

If there are no visible indications of leaking and still the compressor doesn’t work well, then it’s faulty. The front side has a coolant level indicator showing low levels if refilling or recharging is required.

Also, whenever your compressor fails before displaying any sign such as leakage, detecting its location from running without using it will help. Find where that component got weak points causing this problem after all troubleshooting is done for optimal efficiency.

To Recap

The water heater is essential for our homes, but sometimes problems can occur with its components. If you suspect an issue with your A004 water heater, it’s not a bad idea to try fixing the problem by yourself.

One common problem that might arise in the A004 model is known as an ‘A004 Error.’ This happens when there are issues with the compressor. In case of such an error, firstly ensure that there aren’t any electrical issues present around either fan or compressor. This could be checked through continuity testing (reading greater than 60V).

It would help if you also kept checking regularly whether filter screens have become clogged. Clear them out accordingly so they don’t cause unwanted complications down the line! Finally, while inspecting these areas meticulously, look out for oily residue where refrigerant leakage seems likely. It must be addressed sooner rather than later.

If despite thorough inspection compressors still appear faulty, replace them promptly. Along with replacement leaky filters, new ones-upper-casing has several compartments arranged ergonomically. It makes replacements durable, ensuring ideal functionality. Remember, having promptitude from observation to replacement will save money, time, and effort. It will probably save frustration too in future instances where malfunction becomes inevitable again.