R134a Charge as Liquid or Vapor – Recharge Guidelines

Charging systems with R-134a refrigerant can be done as a vapor or liquid. However, end-users need to abide by the guidelines provided by their equipment manufacturers for specific charging instructions.

Charging as a Vapor

R-134a is a commonly used refrigerant in various systems such as automotive A/C, commercial A/C and refrigeration units. Charging with R-134a can be done either as a liquid or a vapor, depending on the specific requirements of the system being serviced.

How to Charge With R-134a as a Vapor

Charging with R-134a as a vapor entails injecting the refrigerant into the system’s low-pressure side while it is running. Typically, an electronic charging scale connected via hoses to containers holding R-1434aba’ or evacuated receiver tank fitted for recovery/recycling equipment such as unit should have valves that allow refrigerant entry and outlet control during the retrofitting process.

When moving vaporous fluid through a secondary container, the technician must verify that a sufficient vacuum is pulled before introducing any new material. Then, by tracking the content entering the receivers, the consistent ambient pressure and temperature are checked.

High accuracy balance gauges display the equilibrium phase between refilling chambers when it is zero.

Advantages and Disadvantages of Charging as a Vapor

One advantage of charging with R-1434 purely N-gas is that no CFCs or HCFCs are released. This could have an impact on our ecology because the value of Ozone depletion is constrained internationally.

It is causing them to consume illegal substances. Safe alternatives are especially beneficial in working contexts. Since many nations are regulating these substances under the Montreal Protocol, other ecologically friendly policies affecting climate change are being implemented.

One disadvantage would be a larger possible risk of exposure when handling compressed gas structures. Furthermore, without sufficient training, only qualified individuals are permitted to operate linked machinery besides leak detection.

It ensures high performance while eliminating downtime and waste scrap repairs. idealized efficiency in an idealized setting minimizes energy use. It maintains consistent inventory while reducing operational expenses, improving mixed solvent conversion rates, and upgrading eco-friendly solutions.

Furthermore, future-proof facilities that want to lower their carbon footprint achieve increased service life maintenance cost-effective predictability. While automating daily operations, avoid substantial reliance on manual labor input based on memory recall or custom know-how.

Safety Precautions

If not done appropriately, charging as a vapor can pose various safety issues, including potentially hazardous gas leaks and skin/eye damage exposure to technicians conducting those activities.

These considerations should be taken seriously at all times when performing these activities and handling any high-pressure equipment. Always use adequate Personal Protective Equipment.

(PPE). Wearing gloves, goggles for eye protection, and a coverall proofed against external chemicals are all part of the process. While ensuring sufficient ventilation, ensure that the valve covers are secure when liquid evacuates the surrounding environment.

It accounts for nearby items and detects fumes/smell leaks to reduce health risks. That incidents occur as a result of following instruction manuals ensures that quality standards are scrupulously followed.

Environmental impact is also being assessed. Making sure that sustainable choices are driven by preserving the earth’s resources, saving energy, and encouraging ongoing improvements that benefit future generations.

crucially increased functionality Creating a retrofit plan methods unique project execution needs long-term compatibility feasible flourishing. within the hydrocarbon industry Green job creation awareness education is being promoted as part of the going green notion.

More about different options that individuals can use interchangeably over time, leading to a massive. Change general corporate perspectives, eventually pushing customers to choose environmentally responsible actions.

Spreading ideology and making the world a greener environment is one step ahead of daily living installations and equipment upgrading. monitoring performance Improving new technological breakthroughs will provide opportunities for growth.

Charging as a Liquid

How to Charge With R-134a as a Liquid:

R-134a can be charged as a vapor or a liquid, although this section will concentrate on charging the refrigerant in liquid form.

Before beginning any refilling procedure, it is critical to check that the device being charged is using R-134a rather than other refrigerants. End users should also consult the manufacturer’s guidelines for particular information on how to replenish their system.

The next step would be to connect your A/C machine’s low-pressure side hose to an air conditioner’s service port. After you’ve created contact between these two pieces of machinery, turn off all valves on the machine.

(i.e., hose and AC unit).

Following that, one might attach their freon bottle to another end tip positioned above our equipment before starting the transfer into such instrument panel/system.

Continuing to exercise caution when handling operations at each stage until completely done putting back what was taken out previously. In terms of coolant levels, required devices are regarded safe from engaging too frequently due to primarily undesirable circumstances.

Such hazards may even result in total loss of ability, operational status, and unanticipated damages that disturb smooth processes. Good workflows made it possible for some brands’ products to be incompatible with the relevant systems implemented by manufacturers.

They are dependable; otherwise, switching up make model fully suggested sources is advised.

Advantages and Disadvantages

The benefits of charging machines that use liquids include easy monitoring of fluid additions and exact quantity released data. Its auto-shut characteristics enable cooling functions to be shut down completely automatically.

It is disseminated carefully throughout the apparatus. Moreover, charging as a liquid can significantly increase the cooling effect. Good cooling within the system prior to conversion into gas results in increased efficiency.

It is important to consider the potential drawbacks of this approach; longer use results in increasing condensation levels. It is causing compressor burnout or other technical issues, which may necessitate repairs for certain customers.

Some recommend avoiding exaggerating the optimal amount charged any item regardless of manufacturer specifications. Anyone intending to do so is recommended to proceed with extreme caution in order to reduce the likelihood of complications costing substantial financial resources to repair or replace future suitability totally.

Safety Precautions

To charge R-134a as a liquid, specific safety standards must be followed in order to avoid severe injury. As a result of refrigerant contact during application, it is very flammable.

And inhalable causes frostbite cases when adequate equipment is not utilized contain taking hazardous consequences. Accepting recommendations seriously ensures better readings, more production, and dependable piece machinery for extended periods of time.

While always keeping hazards in mind, handling compounds intrinsic characteristics potential hazards carefully monitored task done perfectly the first time.

Retrofitting With R-134a

The use of R-12 refrigerant has been discontinued due to its harmful impact on the environment and health risks associated with it. As a result, retrofitting older systems to more sustainable options is becoming increasingly common.

What is Retrofitting?

Retrofitting is the process of replacing an existing system or piece of equipment with modern technology in order to increase efficiency, usability, and eliminate potential environmental concerns.

Retrofitting in this context involves replacing the old R-12 refrigerant used in air conditioning systems with R-134a, which is safer for both humans and the environment.

Retrofitting Using R-134a

It can be difficult to transition older systems from using old refrigirants like R – 12 to using new ones like CO2 or HFOs. However, the change to a better method almost always results in improved operational conditions.

Despite the introduction of improved replacements and alternatives for freon systems, the most often utilized refrigerant at the moment is the HFC-based fluid, R – 134A.

Benefits of Retrofitting Existing R-12 Systems

The benefits of converting old air conditioning systems to use the R-134a refrigerant include:

Environmental safety: Because of their hazardous impact on the ozone layer, the extensively used CFCs and HCFCs in older AC units have been phased out. Adoption of HFCs during retrofitting reduces this impact due to their high GWP value, and so is a viable choice for systems with low rvaporation rates, such as freezing and refrigeration applications.

Cost Saving: It also saves a lot of money.

Improved Efficiency: Because of its superior cooling capabilities, R – 134A produces exceptional performance at various pressure levels. Its variable operating capability significantly improves operational efficiency since the viscosity allows for more efficient heat conduction between parts.

There are larger capacities, volume flow rates, and superior oil compatibility with fewer component issues during use.

Replacing outmoded A/C systems from old technology to modern options may take time and correct planning, but it creates safer working conditions, fewer health concerns, and a lower carbon footprint, among many other benefits previously stated.

Applications of R-134a

Refrigeration

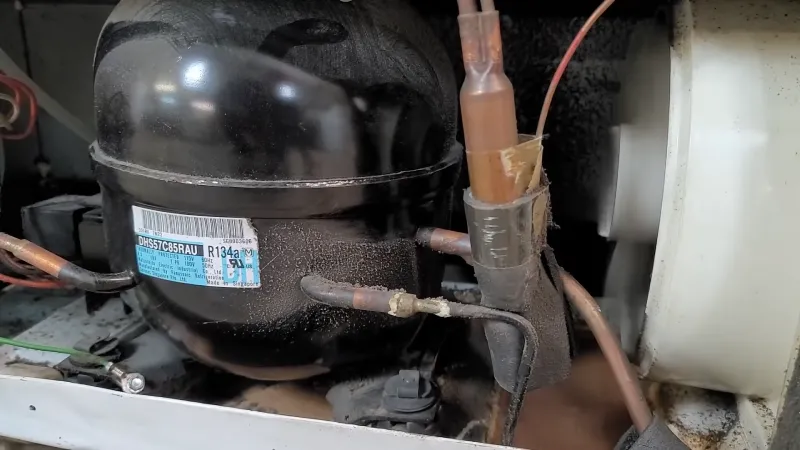

R-134a is frequently used as a refrigerant in a wide range of refrigeration applications, including domestic and commercial refrigerators. It has excellent thermodynamic properties that make it quite effective for use in these systems.

Unlike other alternatives such as R12, R-134a does not harm the ozone layer.

Automotive a/c Systems

Another essential application for this chemical is its use to power automotive air conditioning (AC) systems. Most modern automobiles use either 100% R-134a or a combination of various cooling agents incorporating considerable amounts of the compound.

Due to its superior heat transfer performance while keeping compressor requirements minimal.

Commercial Air Conditioning Systems

Dryers/dehumidifiers powered by air conditioning systems are very beneficial in large scale heating ventilation and manufacturing. Again, coolants based on HFCs, such as r/freon, are typically deemed appropriate because they do not deplete the ozone layer.

That means that when working with large HVAC equipment that are regularly used in industrial settings, replacement costs might be enormous. for lengthy periods of time that necessitate substantial customisation prior to installation, owing to their massive size and capacity.

It must be capable even at high temperatures.

Charging Techniques

The charging process demands specific techniques depending on whether you’re recharging an existing system utilizing alternative/ retrofit substances. Or adding Gas into one fresh off construction job where there might be no internal parts damage/problems whatsoever after manufacture & testing.

Liquid Charging Technique

Useful primarily during recovery operations for larger installations that require vacuums to suction away moisture/water, etc. This ensures thorough evacuation while also preventing blockage by installing filters within pipelines ahead of time.

Pumping equipment also ensures the safety of service personnel because most liquid containers include leak-proof valves. The valves shut uncontrolled gas release chances quickly, considerably reducing fire/explosion hazards and streamlining complete operations.

Overall, lowering error potential caused by uncertainty-related handling of volatile Chemical’s dangerous fumes.

Vapor Charging Technique

This technique is more preferred, as it’s environmentally safer during one-time or multiple recharge procedures. Refrigerant gas in liquid form requires significant attention since external exposure cases can cause human/animal life-risk along with releasing dangerous volatile organic compounds VOCs directly into the atmosphere.

R-134a has become an industry standard due to its great qualities and efficient usage in a variety of systems. This necessitates an abundance of cooling benefits for accurate temperature regulation.

Particular emphasis is placed on large-scale HVAC equipment that serve industrial applications on a daily basis, where the repair/replacement costs of incorrect installations are enormous. The tank weight is also important.

When under heavy operation 24 hours a day, seven days a week, without proper expert maintenance/supervision. It has the potential to cause catastrophic failures, severe stress-overtime payouts, and jeopardize business operations.

Furthermore, profitability eventually leads to a sudden shutdown/collapse. And endangering livelihoods/jobs/lives is a legitimate issue that necessitates correct handling techniques/guidelines based on the recommendations of experienced specialists.

Do You Charge Refrigerant as a Liquid or Vapor?

When adding refrigerant to a system, it is important to use vapor. This avoids flooding the compressor with liquid and causing damage. Vapor charging can also help prevent air from entering the system.

Charging as a liquid may result in uneven distribution throughout the coils. However, some systems require low-side charging as a liquid for proper operation. Consult manufacturer guidelines before deciding on which method of charging to use.

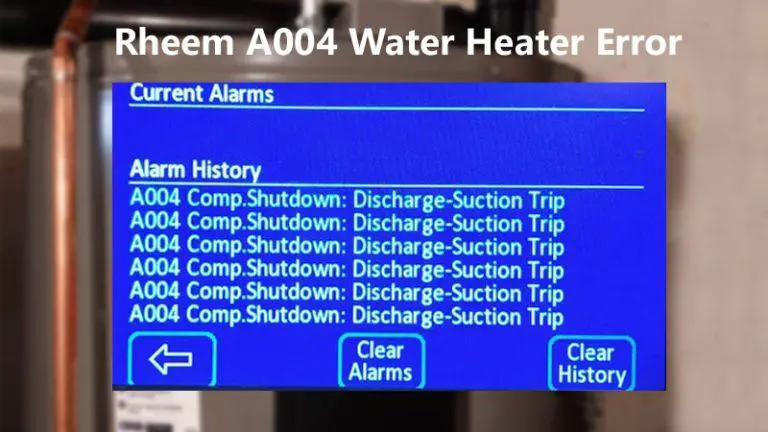

When adding refrigerant, it is critical not to overcharge or undercharge the system. Overcharging raises energy expenditures and reduces efficiency, whilst undercharging can lead to compressor failure.

Attempting to add too much refrigerant at once is risky and should be avoided. For best operation, regular maintenance by an HVAC professional is suggested.

To Recap

Retrofitting existing R-12 systems is possible using R-134a that makes it an ideal candidate in various applications such as automotive A/C and commercial A/C systems alongside refrigeration.

As you choose between liquid and vapor charge method, make sure to follow manufacturer’s recommended methods at all times.

![Why Would Someone Run Their Air Conditioner in the Winter? [Pros, Cons, Expert Tips]](https://fixitinthehome.com/wp-content/uploads/2023/02/Sydney-Air-conditioning-installation-Daikin-wall-split-system-2-27-screenshot-768x432.webp)