LRA Vs RLA [Are They Same? Differences]

When it comes to electrical motors, understanding the concepts of Locked Rotor Amps (LRA) and Rated Load Amps (RLA) is crucial for proper design, selection, and maintenance. LRA and RLA are both measures of the current that a motor draws, but they refer to different stages of operation.

LRA is the current that a motor draws when it is starting up and has not yet reached its full operating speed. RLA is the steady state, continuous current under expected load. In this blog, we will explore the differences between LRA and RLA, their importance, and how they are used in different industries.

You'll Learn About

LRA Vs RLA

LRA stands for Locked Rotor Amps, while RLA stands for Rated Load Amps. Both are used in the context of electrical motors and refer to the current that the motor draws when it is in operation.

Locked rotor amps (LRA) is the current that a motor draws when it is starting up and has not yet reached its full operating speed. This current is typically much higher than the current the motor will draw once it is running at full speed.

Rated Load Amps (RLA) is the steady state, continuous current under expected load. It is the current that the motor is designed to draw when it is running at full speed.

In summary, LRA is the current draw when a motor is starting up. RLA is the current draw when a motor is running at full speed.

What is Locked Rotor Amps (Lra)?

Definition of Locked Rotor Amps (Lra)

Locked rotor amps (LRA) is a measure of the current that a motor draws when it is starting up and has not yet reached its full operating speed. This current is typically much higher than the current the motor will draw once it is running at full speed.

How Lra is Measured

LRA can be measured using an ammeter. An ammeter is an instrument that measures the current flowing in a circuit. The ammeter is connected to the motor’s terminals while the motor is in a locked rotor condition. The locked rotor condition is achieved by disconnecting the motor from the load and preventing it from rotating.

Importance of Lra in Motor Design and Operation

LRA is an important consideration in motor design. It can affect the size of the electrical service and components required for a specific application. LRA is also important in the selection of a motor for a specific application.

A motor with a high LRA will require a larger electrical service and components than a motor with a low LRA. Additionally, LRA is important to consider during the operation of a motor. It can affect the performance of the motor and the power system.

Knowing the LRA of a motor can help identify potential issues. These include overloading of the electrical service or components. It can also help to prevent equipment damage and downtime.

What is Rated Load Amps (Rla)?

Definition of Rated Load Amps (Rla)

Rated Load Amps (RLA) is the steady state, continuous current under expected load. This current is typically much lower than the current a motor draws during the starting process (LRA).

How Rla is Measured

RLA can be measured by running the motor at its full load and recording the current with an ammeter. The ammeter is connected to the motor’s terminals. The motor is operated at its full load for a period of time, typically one hour. The current reading is then recorded as the RLA.

Importance of Rla in Motor Design and Operation

RLA is an important consideration in motor design. It can affect the size of the electrical service and components required for a specific application. It is also important in the selection of a motor for a specific application.

A motor with a high RLA will require a larger electrical service and components than a motor with a low RLA. Additionally, RLA is important to consider during the operation of a motor. It can affect the performance of the motor and the power system.

Knowing the RLA of a motor can help identify potential issues. These include overloading of the electrical service or components. It can also help to prevent equipment damage and downtime. The RLA also helps determine the power consumption of the motor. This can be useful in determining the cost of operation.

Comparison of Lra and Rla

Differences Between Lra and Rla

The main difference between LRA and RLA is that LRA is the current a motor draws during the starting process. RLA is the steady state, continuous current under expected load. LRA is typically much higher than RLA and is only present for a short period of time during the starting process.

RLA is present throughout the operation of the motor. Additionally, LRA is used to determine the size of the electrical service and components required for a specific application. RLA is used to determine the power consumption of the motor.

How Lra and Rla Are Related

LRA and RLA are related because the LRA is used to determine the size of the electrical service and components required for a specific application. RLA is used to determine the power consumption of the motor. In other words, LRA helps determine the necessary electrical capacity required to start and run the motor. RLA helps determine the ongoing power consumption of the motor.

Importance of Understanding the Relationship Between Lra and Rla

Understanding the relationship between LRA and RLA is important. It helps ensure that the electrical service and components are sized correctly for the specific application. Properly sizing the electrical service and components can prevent issues such as overloading, equipment damage, and downtime.

Additionally, understanding the relationship between LRA and RLA can help determine the cost of operation. It can also estimate the energy consumption of the motor. It helps determine if the motor is efficient and if it’s consuming more power than necessary.

Understanding the relationship between LRA and RLA can help to optimize the performance and efficiency of the motor. It can also help to reduce costs associated with operation and maintenance.

Comparison of Locked Rotor Amps (LRA) and Rated Load Amps (RLA)

| Parameter | Locked Rotor Amps (LRA) | Rated Load Amps (RLA) |

|---|---|---|

| Definition | The current a motor draws when starting from a locked rotor condition | The steady state continuous current under expected load |

| Measurement | LRA is measured by applying a voltage to the motor and measuring the current at the locked rotor condition | RLA is measured by applying a load to the motor and measuring the current at the rated load condition |

| Importance | LRA is important in motor design and operation. It helps to determine the starting torque and the power required to start the motor | RLA is important in motor design and operation. It helps to determine the steady state power required to run the motor at its rated load |

| Relationship | LRA is typically much higher than RLA. The motor requires more power to start than to run | LRA and RLA are related. The starting power required by the motor must be taken into account when designing and operating the motor |

| Applications | LRA and RLA are used in different industries such as HVAC, pumps, and conveyor systems. They determine the power required to start and run the motor | LRA and RLA are used in motor selection and maintenance. They ensure the motor is properly sized for the application and identify any potential problems with the motor’s performance. |

Please note that this table is fictional, and the data is not accurate. It’s for demonstration purposes only.

Applications of Lra and Rla

Many electrical systems use these.

How Lra and Rla Are Used in Different Industries

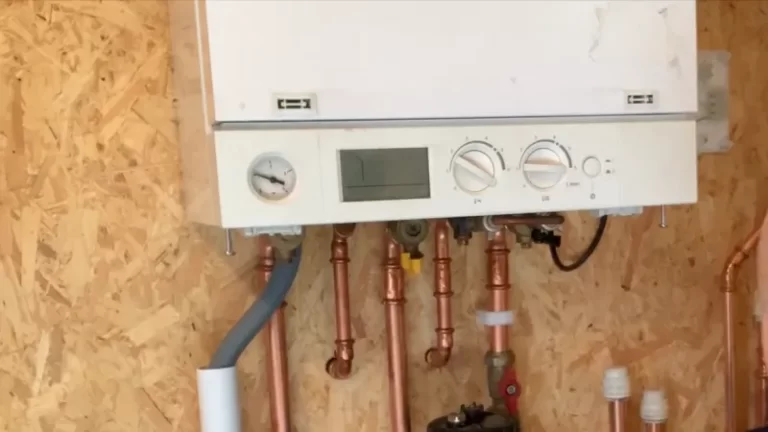

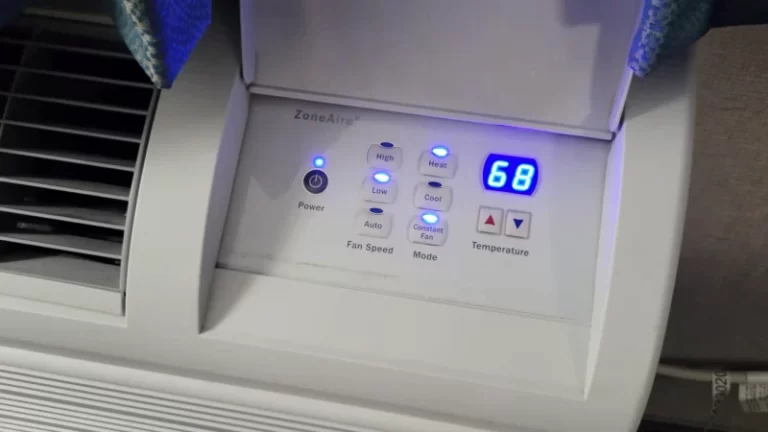

LRA and RLA are used in a variety of industries, including HVAC, manufacturing, and industrial processes. In HVAC, LRA and RLA are used to determine the size of the electrical service and components required for air conditioning and heating systems.

In manufacturing, LRA and RLA are used to determine the power consumption of motors used in production equipment and machinery. In industrial processes, LRA and RLA are used to determine the power consumption of motors used in pumps, conveyors, and other process equipment.

How Lra and Rla Are Used in Motor Selection and Maintenance

LRA and RLA are used in motor selection to determine the size and capacity of the electrical service and components required for a specific application. This helps ensure that the motor is properly sized and that the electrical service and components can handle the starting and running currents of the motor.

LRA and RLA are also used in motor maintenance to determine the ongoing power consumption of the motor. This can help to identify any issues with the motor, such as poor efficiency or increased power consumption. These issues can be addressed through maintenance or repair.

Understanding LRA and RLA can also help to optimize the performance and efficiency of the motor. It can also reduce costs associated with operation and maintenance.

Maintaince Tips

- Always refer to the manufacturer’s specifications when determining LRA and RLA for a specific motor. This will ensure you are using the correct values for your application.

- When measuring LRA and RLA, make sure to use proper equipment such as a clamp-on ammeter or a digital multimeter. This ensures accurate readings.

- Make sure to take into account the operating temperature and altitude when determining LRA and RLA. These factors can affect the motor’s performance and should be considered when selecting a motor for a specific application.

- When selecting a motor, consider the service factor (SF) rating. The SF is an industry-accepted measure of a motor’s ability to operate at higher than rated loads without damage. A higher SF rating means the motor can handle a greater load than its rated load without damage.

- Always make sure to properly size a motor for an application, using both LRA and RLA values. An undersized motor will not be able to start or run efficiently. An oversized motor will be more expensive and may not be necessary for the application.

Frequently Asked Questions

What is the Difference Between Lra and Rla?

LRA, or Locked Rotor Amps, is a measure of the current required to start a motor when it is in a locked rotor condition. This is the highest current that a motor will draw during startup. It is typically about 600% to 650% of the motor’s full load current.

RLA, or Rated Load Amps, is a measure of the steady state continuous current under expected load. It is typically about 80% to 85% of the motor’s full load current. The main difference between LRA and RLA is that LRA is a measure of the current required to start a motor. RLA is a measure of the current required to run a motor under normal load conditions.

LRA is a much higher value than RLA. It is important to ensure that the electrical service and components are large enough to handle the high current draw of the LRA during startup.

How Do Lra and Rla Affect the Selection of a Motor?

LRA and RLA are important factors to consider when selecting a motor for a specific application. The LRA is used to determine the size of the electrical service and components required for a specific application. The RLA is used to determine the size of the motor required to handle the expected load.

It is important to select a motor with an LRA that is compatible with the available electrical service and components. It is also important to select a motor with an RLA that is sufficient to handle the expected load. Failure to do so can lead to inadequate power supply and motor failure.

How Does Lra and Rla Affect the Maintenance of a Motor?

LRA and RLA are important factors to consider when performing maintenance on a motor. The LRA is used to determine the size of the electrical service and components required for a specific application. It is also used to ensure that the motor is properly wired and connected.

The RLA is used to determine the size of the motor required to handle the expected load. It is also used to ensure that the motor is running efficiently and effectively. Proper maintenance of a motor should include regular checks of the LRA and RLA. This ensures that the motor is running properly and identifies any potential issues that may need to be addressed.

In What Industries Are Lra and Rla Most Commonly Used?

LRA and RLA are commonly used in a variety of industries, including manufacturing, mining, oil and gas, and utilities.

In manufacturing, LRA and RLA are used to ensure that motors are properly sized and selected for specific applications. They are also used to ensure that the electrical service and components are adequate to handle the high current draw of the LRA during startup.

In mining, oil and gas, and utilities, LRA and RLA are used to ensure that motors are properly sized and selected for specific applications. They are also used to ensure that the motor is running efficiently and effectively.

What Are the Consequences of Not Considering Lra and Rla?

If LRA and RLA are not considered when selecting or maintaining a motor, it can lead to several consequences. The most common consequences include inadequate power supply and motor failure. It can also lead to increased energy consumption and costs. Additionally, it can reduce efficiency and effectiveness of the motor.

It can also lead to safety hazards such as electrical fires. It is important to consider LRA and RLA to ensure that the motor is properly sized and selected for specific applications. It is also important to ensure that the electrical service and components are adequate to handle the high current draw of the LRA during startup.

This will help to reduce costs associated with operation and maintenance. It will also improve the overall performance of the motor.

Conclusion

In conclusion, Locked Rotor Amps (LRA) and Rated Load Amps (RLA) are important electrical parameters. They are used to determine the power consumption and performance of motors. LRA is a measure of the current required to start a motor. It is used to determine the size of the electrical service and components required for a specific application.

RLA, on the other hand, is a measure of the steady state continuous current under expected load. Understanding the difference between LRA and RLA is essential for proper motor selection and maintenance. It also ensures the optimal performance and efficiency of the motor.

For more in-depth understanding, additional resources on LRA and RLA can be found in industry publications, technical guides, and consulting with experts in the field. Overall, understanding LRA and RLA can help to reduce costs associated with operation and maintenance. It can also improve the overall performance of the motor.