Crimp PEX Without a Tool? The #1 Secret Plumbers Won’t Tell You

You are in the middle of a plumbing project. Water is off, the family is waiting, and you have a PEX pipe that needs a connection. There is just one problem: you do not have a PEX crimp tool. It is a situation that sends many homeowners scrambling for a solution, wondering if there is a way to crimp PEX without the designated tool.

The immediate, critical answer is a firm no. You cannot properly or safely crimp a PEX ring without a calibrated PEX crimping tool. Attempting to use pliers, a vise, or any other makeshift device is a recipe for a slow leak, a catastrophic burst, and significant water damage down the line. The secret isn’t finding a clever way to bypass the tool; it’s knowing the professional alternatives that don’t require a crimper at all.

You'll Learn About

Why Makeshift “Crimping” Methods Are a Guaranteed Plumbing Disaster

To understand why you cannot improvise a PEX crimp, it is important to understand what the tool actually does. A PEX crimping tool is designed to apply a precise, uniform 360-degree pressure to the copper crimp ring. This pressure compresses the ring, the PEX pipe, and the fitting’s barb into a single, watertight unit that is meant to last for decades.

When you try to replicate this with a pair of pliers or a vise, you create uneven pressure points. This not only fails to create a complete seal but can also damage the integrity of the PEX tubing and the fitting itself. These makeshift connections might seem to hold initially, but they create stress points that are almost certain to fail under the constant pressure and temperature fluctuations of a home’s water system.

The Hidden Dangers of an Improper Seal

A failed PEX connection behind a wall or under a floor can go unnoticed for weeks, silently leaking water into your home’s structure. This can lead to thousands of dollars in damage from rot, mold growth, and compromised structural integrity. The risk is simply not worth the perceived savings of skipping the proper tool or method.

The subtle signs of a failing connection can be elusive. You might notice a faint musty odor, unexplained humidity, or minor warping in flooring or drywall. By the time these symptoms become obvious, extensive damage has often already occurred. This is why professional plumbers exclusively use methods that guarantee a secure, long-lasting seal from the very beginning.

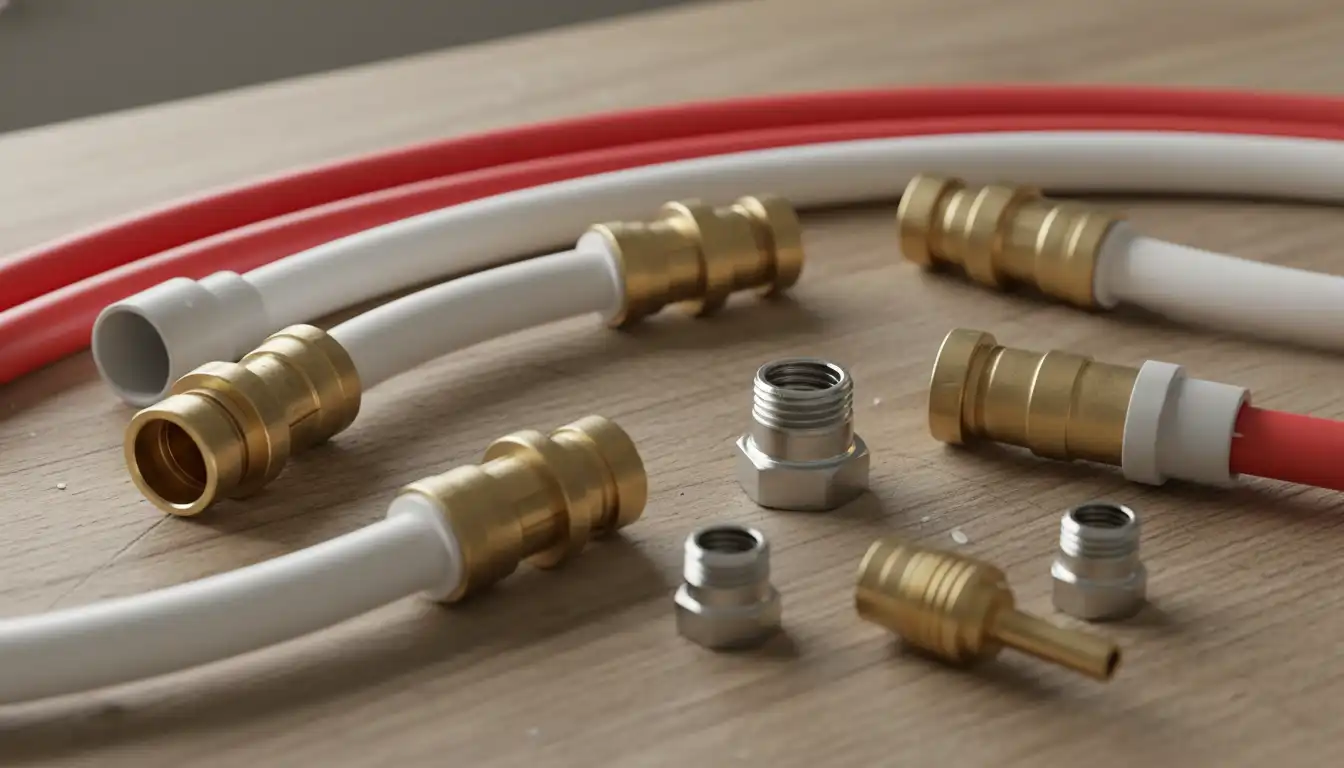

The Real Solution: How to Connect PEX Without a Crimp Tool

The true secret to handling this situation is not to find a hack for crimping, but to use professionally-approved fittings that are specifically designed for tool-free or minimal-tool installation. Instead of asking how to crimp without a tool, the better question is: “How do I connect PEX without a crimp tool?” Fortunately, there are excellent, reliable options available.

These methods are trusted by both professionals for quick repairs and DIYers for their simplicity and reliability. They provide a secure, leak-proof connection without the need for a specialized and often expensive crimping or clamping tool. Understanding these alternatives is key to completing your project safely and effectively.

Method 1: Push-to-Connect (Push-Fit) Fittings – The DIY Favorite

Push-to-connect fittings, widely known by the brand name SharkBite, are the most popular and accessible tool-free solution for PEX plumbing. These ingenious fittings use a system of a stainless steel grab ring and a rubber O-ring to create a secure seal. When the PEX pipe is inserted, the grab ring’s teeth bite into the pipe, holding it firmly in place while the O-ring creates a watertight barrier.

Their popularity stems from their incredible ease of use. They are an excellent choice for repairs in tight spaces or for homeowners who do not plan on doing enough plumbing work to justify purchasing a crimp tool. They are approved for permanent installation behind walls and underground, offering a reliable connection that can last for years.

Step-by-Step Guide to Installing Push-to-Connect Fittings

Installing a push-fit fitting is a straightforward process that requires only a pipe cutter and a deburring tool.

1. Make a Clean, Square Cut: Use a dedicated PEX cutter to ensure the end of the pipe is perfectly square. A hacksaw or utility knife can create burrs and an uneven surface, which can damage the O-ring and prevent a proper seal.

2. Deburr the Pipe: After cutting, smooth the inside and outside edge of the pipe with a deburring tool. This small step is critical to protect the fitting’s O-ring from being sliced or damaged during insertion, which is a common cause of leaks.

3. Mark the Insertion Depth: Use the manufacturer’s depth gauge (or measure according to their specifications) to mark how far the pipe needs to be inserted into the fitting. This visual confirmation ensures the pipe has passed the O-ring and is fully seated.

4. Push to Connect: With a firm, steady motion, push the PEX pipe into the fitting until it meets the mark you made. You will feel a distinct “click” as the grab ring engages and the pipe seats fully. That is all there is to it; the connection is made.

Method 2: Compression Fittings – The Old-School Reliable Choice

Compression fittings are another excellent method for connecting PEX without a crimp tool. This style of fitting has been used in plumbing for decades and creates a seal by mechanical pressure. It consists of three main parts: the fitting body, a compression ring (or ferrule), and a compression nut.

As you tighten the nut, it forces the compression ring into the tapered seat of the fitting body, compressing it tightly against the PEX pipe. This creates a very strong and reliable mechanical seal. While they require a pair of wrenches to tighten, they do not need any specialized PEX tools.

Step-by-Step Guide to Installing Compression Fittings

Proper installation is key to a leak-free compression fitting.

1. Cut and Prepare the Pipe: Just as with push-fit fittings, start with a clean, square cut on the PEX pipe and ensure the end is free of burrs.

2. Assemble the Components: Slide the compression nut onto the PEX pipe first, ensuring the threads are facing the end of the pipe. Then, slide the compression ring (ferrule) onto the pipe.

3. Insert the Pipe: Push the PEX pipe into the body of the fitting until it bottoms out. The pipe must be fully inserted to ensure a proper seal.

4. Tighten the Nut: Slide the compression ring and nut down to meet the fitting body and hand-tighten the nut. Then, using two wrenches—one to hold the fitting body steady and one to turn the nut—tighten the nut another half to three-quarters of a turn. Be careful not to over-tighten, as this can damage the pipe or the fitting.

Comparing Your Tool-Free PEX Connection Options

Choosing between push-to-connect and compression fittings often comes down to the specific application, budget, and personal preference. Both are reliable alternatives to crimping, but they have distinct advantages and disadvantages.

The following table breaks down the key differences to help you decide which method is best for your project.

| Feature | Push-to-Connect (Push-Fit) | Compression Fittings |

|---|---|---|

| Ease of Use | Extremely easy; no tools required for connection. | Moderately easy; requires two wrenches for tightening. |

| Installation Speed | Very fast, connects in seconds. | Slower, requires careful tightening. |

| Cost per Fitting | Higher, can be significantly more expensive. | Lower, generally more budget-friendly. |

| Required Tools | Pipe Cutter, Deburring Tool. | Pipe Cutter, Two Adjustable Wrenches. |

| Reusability | Yes, can be removed with a special clip and reused. | Sometimes, but it’s often recommended to replace the compression ring. |

| Best For | Emergency repairs, tight spaces, DIYers, transitions between pipe types. | Exposed connections (like shut-off valves), applications requiring high durability. |

When to Use Tool-Free Fittings in Your Home Projects

Tool-free fittings are incredibly versatile and can be a lifesaver in many common home improvement scenarios. They excel in situations where speed, simplicity, or working in confined spaces is a priority. For example, when you need to move sink plumbing over a few inches, a push-fit elbow can make the job dramatically easier than trying to maneuver a crimp tool under a cabinet.

Similarly, the task of replacing a shower faucet with a different brand often involves adapting new connections to existing pipes behind the wall. Push-to-connect adapters can simplify this transition, saving time and frustration. Even in larger projects, like moving your washer and dryer to another wall, these fittings can be used for final connections or in hard-to-reach areas to complement a larger crimped system.

The Professional’s Perspective: Is it Worth Buying a PEX Crimp Tool?

While tool-free fittings are excellent solutions, there is a reason why crimp and clamp systems remain the standard for new construction and full-scale plumbing installations. The primary factors are long-term cost and the established track record of crimped connections when properly installed.

For a large project, the higher cost of push-to-connect fittings can add up quickly. A basic PEX crimp tool can pay for itself over the course of a single bathroom remodel when compared to the cost of using dozens of push-fit tees and elbows. Furthermore, a properly crimped connection is generally considered a “permanent” installation with a very low failure rate, offering ultimate peace of mind for connections that will be sealed behind finished walls for decades.

Long-Term Cost and Reliability

Think of it as a trade-off between upfront investment and per-fitting cost. If you anticipate doing several plumbing projects in the future, investing in a quality crimp or clamp tool is a wise financial decision. However, for a single, small repair or a project with just a few connections, the convenience and reliability of push-to-connect or compression fittings are unmatched.

Ultimately, the best method depends on the scale of your work and your comfort level. Both crimped and high-quality tool-free fittings will provide a safe, leak-proof system when installed according to the manufacturer’s instructions.

Final Verdict: Don’t Crimp Without a Tool, Connect Without One

The mission to “crimp PEX without a tool” should be reframed. Instead of seeking a dangerous shortcut, the goal is to learn the correct, safe, and reliable methods to connect PEX without a specialized crimper. Push-to-connect and compression fittings are not just DIY workarounds; they are code-approved, professional-grade solutions that offer a secure alternative.

For your next plumbing project, resist the temptation to grab a pair of pliers. Instead, equip yourself with the right knowledge and the right alternative fittings. By doing so, you ensure the safety, longevity, and integrity of your home’s plumbing system, turning a moment of potential panic into a display of informed and confident handiwork.