Snowblower Smells Like Gas? Don’t Ignore This Warning Sign!

That unmistakable, pungent smell of raw gasoline wafting from your snowblower is more than just an unpleasant odor; it’s a critical warning sign. Ignoring it can lead to serious safety hazards, including fire risks, and can indicate underlying engine problems that will only worsen over time. This guide will walk you through the most common reasons your snowblower smells like gas and provide actionable, step-by-step solutions to fix the problem safely and efficiently.

Understanding the source of the fuel smell is the first step toward a reliable and safe machine. Whether it’s a simple fix or a more complex carburetor issue, addressing it promptly ensures your snowblower is ready to tackle the next storm without putting you or your property at risk.

You'll Learn About

Why You Can’t Ignore the Smell of Gas

A gasoline odor around your snowblower is a clear signal that fuel is present where it shouldn’t be. Raw, liquid gasoline or its potent vapor is highly flammable and can ignite from a simple spark, such as the one from the engine’s own ignition system or static electricity. This creates a significant fire hazard that cannot be taken lightly.

Beyond the immediate safety risks, a persistent gas smell often points to a fuel system malfunction. This could mean your engine is running too rich (using too much fuel), which wastes gas, increases emissions, and can eventually foul the spark plug and damage the engine. It can also indicate a leak that, if left unaddressed, could lead to more costly repairs down the line.

Top 5 Reasons Your Snowblower Smells Like Gas (And How to Fix Them)

Most fuel smell issues can be traced back to a handful of common culprits. By systematically checking each one, you can diagnose and resolve the problem. Always perform maintenance in a well-ventilated area away from any ignition sources and disconnect the spark plug wire before starting work.

1. The Most Common Culprit: A Carburetor Problem

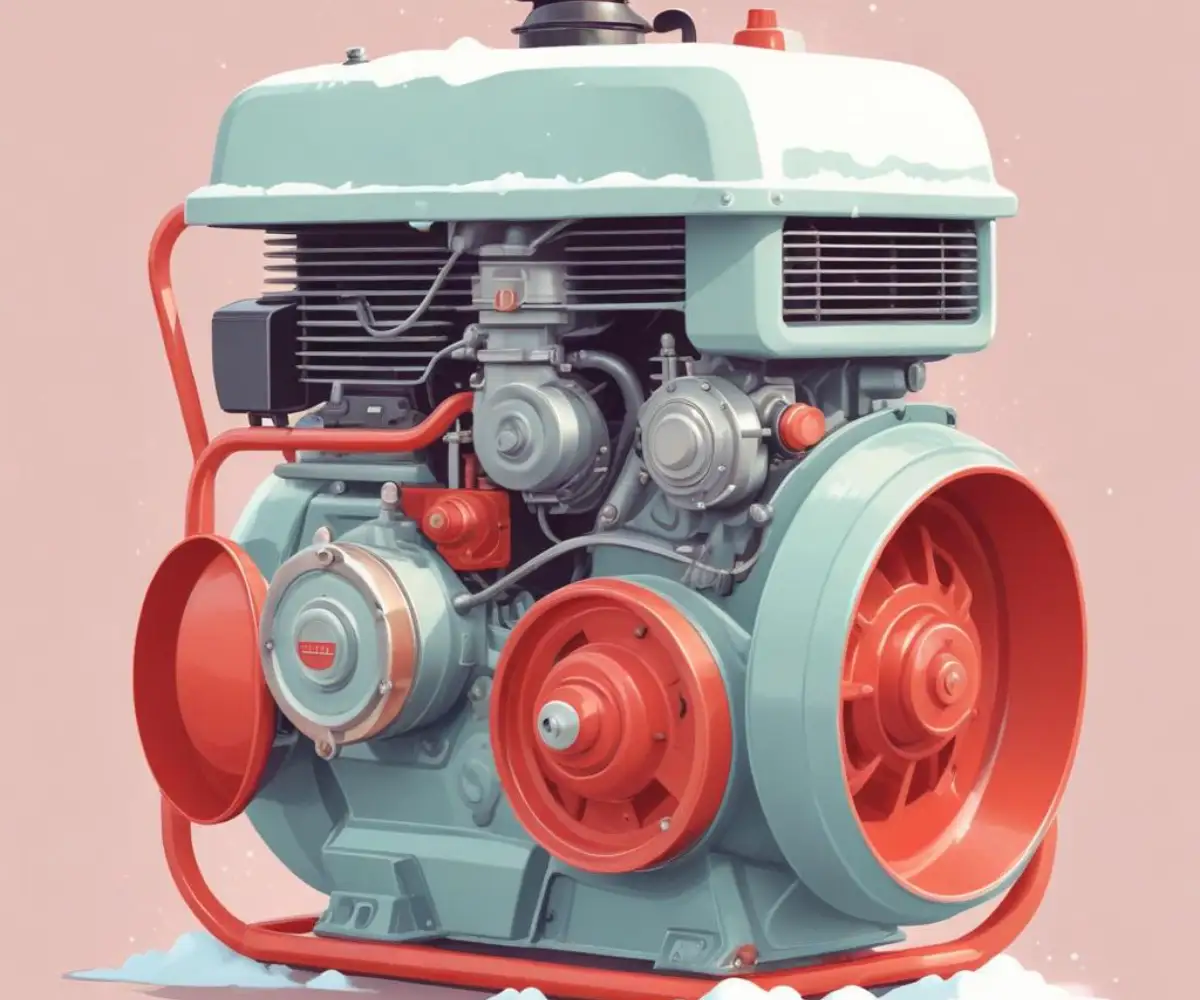

The carburetor is the heart of your snowblower’s fuel system, mixing air and fuel in precise amounts for combustion. When it malfunctions, it’s the most frequent source of gas smells. Several issues can arise within this complex component.

A very common problem is a stuck float or a faulty needle valve. Inside the carburetor is a small reservoir of fuel called the float bowl. As fuel fills the bowl, a float rises and pushes a needle into a seat, stopping the flow of gas. If this needle valve fails to seal properly, gas will continuously overflow, leading to a strong fuel odor and visible leaks. You might wonder, should carburetor bowl be full of gas? While it should be mostly full during operation, a constant overflow indicates a definite problem. Another related issue could be a leaking carburetor gasket. If you notice leaks specifically from this area, it might be time to investigate further. For more detailed guidance, see our post on an Ariens carburetor leaking gas.

Solution: Often, tapping the side of the carburetor bowl firmly with the handle of a screwdriver can dislodge a stuck float. If this doesn’t work, you may need to remove the carburetor bowl, clean the needle and seat with carburetor cleaner, and ensure the float moves freely. If the components are worn, a carburetor rebuild kit is an inexpensive way to replace them.

2. Cracked or Loose Fuel Lines

The rubber or plastic fuel lines that carry gasoline from the tank to the carburetor are constantly exposed to fuel, vibrations, and extreme temperatures. Over time, they can become brittle, crack, or develop loose connections, allowing fuel to seep out. Even a very small, weeping leak can produce a strong gasoline smell.

Solution: Carefully inspect the entire length of the fuel line, from the tank to the fuel shut-off valve and all the way to the carburetor. Pay close attention to the connection points. If you see any cracks or feel wetness, the line must be replaced. Use pliers to slide the clamps off, pull the old line, and install a new fuel line of the same size, securing it with the clamps.

3. A Faulty Gas Cap Seal

This is one of the most overlooked causes of a gasoline smell. The gas cap is designed to vent, allowing air to enter the tank as fuel is consumed, which prevents a vacuum from forming. However, it must also create a seal to prevent fuel vapors and liquid fuel from escaping, especially as the machine vibrates.

The rubber gasket inside the cap can degrade, crack, or become compressed over time, compromising the seal. An improper seal allows gasoline vapors to escape continuously, creating a persistent odor in your garage or shed. Using a non-original equipment manufacturer (OEM) cap can also cause issues, as they may not vent at the correct pressure for your specific model.

Solution: Inspect the gasket inside the gas cap. If it appears damaged, dry, or flattened, replace the gas cap. Opting for a genuine OEM cap is always the best choice to ensure a perfect fit and proper venting, eliminating the smell and ensuring correct engine operation.

4. Engine Flooding: Too Much of a Good Thing

Engine flooding occurs when too much gasoline enters the combustion chamber, overwhelming the spark plug and preventing ignition. This is often caused by over-priming (pushing the primer bulb too many times) or an incorrect starting procedure. The excess, unburnt fuel will evaporate and create a very strong gas smell.

Solution: If you suspect the engine is flooded, do not prime it again. Turn the choke to the “off” or “run” position and set the throttle to full. Pull the starter rope several times. This procedure helps clear the excess fuel from the cylinder. If it still won’t start, you may need to remove the spark plug, let it air dry, and crank the engine a few times with the plug out to expel the rest of the fuel before reinstalling.

5. Old or Improperly Stored Fuel

Gasoline degrades over time. As it ages, the more volatile compounds evaporate, leaving behind a heavier, less combustible fuel that can smell sour or varnish-like. This stale fuel not only causes hard starting and poor performance but can also emit a stronger, more unpleasant odor than fresh gasoline.

Solution: If the fuel in your tank is more than a few months old and was not treated with a fuel stabilizer, it’s best to drain it completely. Dispose of the old fuel according to local regulations and refill the tank with fresh gasoline. Using a fuel stabilizer is crucial, especially for the last fill-up of the season, to keep the fuel system clean and the gas fresh for months.

The Troubleshooting Table: Pinpoint Your Gas Smell

Use this table to quickly diagnose the potential cause of the gas smell based on the symptoms you are observing. This can help you narrow down the issue and focus your repair efforts.

| Symptom | Possible Cause | Recommended Solution |

|---|---|---|

| Strong gas smell with visible drips under the engine. | Leaking carburetor bowl, fuel line, or fuel filter. | Inspect carburetor gaskets, all fuel line connections, and the fuel filter housing. Replace any cracked or damaged parts. |

| Gas smell is strongest after failed starting attempts. | Engine flooding due to over-priming. | Follow the procedure to clear a flooded engine. Avoid excessive priming. |

| A constant, faint gas smell in the storage area, even when the snowblower is cold. | Faulty gas cap seal or vapor permeation through a plastic tank. | Inspect and likely replace the gas cap. Ensure the storage area is well-ventilated. |

| Smell of gas accompanied by black smoke from the exhaust when running. | Engine is running rich. | The carburetor likely needs cleaning and adjustment. Check that the choke is opening fully. |

| Gasoline smell is noticeable in the engine oil (check dipstick). | Internal carburetor leak (stuck float/needle). | This is serious. Fuel is contaminating the oil. Do not run the engine. Repair the carburetor and perform an immediate oil change. |

Beyond the Basics: When the Smell Isn’t a Leak

Sometimes a gas smell doesn’t come from a liquid leak. Gasoline is highly volatile, and its vapors are powerful. On some models, especially older ones, it’s possible for fuel vapors to slowly permeate through the plastic of the fuel tank itself, creating a noticeable odor without any visible wetness.

Additionally, a cracked primer bulb can be a hidden source of a leak. This small rubber bulb can become brittle and develop tiny cracks that weep fuel or vapor, especially when pressed. Carefully inspect the primer bulb for any signs of damage or wetness around its base.

Safety First: Essential Precautions

Working with gasoline requires the utmost caution. It is extremely flammable and its vapors are explosive. Always follow these safety rules before attempting any diagnosis or repair on your snowblower’s fuel system.

Work in a well-ventilated area, preferably outdoors or in a garage with the doors wide open. This prevents the dangerous buildup of gasoline fumes. Ensure there are no open flames or spark sources nearby. This includes pilot lights on water heaters or furnaces, cigarettes, and power tools that can create sparks. Always have a Class B fire extinguisher rated for flammable liquids within easy reach. Before starting any work, disconnect the spark plug wire and secure it away from the spark plug. This prevents any chance of the engine accidentally starting while you are working on it.

What About Oil Smells?

It’s important to distinguish between a raw gas smell and a burning oil smell. A burning oil smell, which is quite different, often indicates an oil leak where oil is dripping onto hot engine components. If you suspect an oil issue, it’s a separate problem that needs investigation. For guidance on that topic, you can learn how to fix an Ariens snowblower leaking oil.

Conclusion: Taking Control of the Situation

A snowblower that smells like gas is a problem that demands immediate attention. By methodically working through the most likely causes—from the carburetor and fuel lines to the gas cap and the fuel itself—you can effectively diagnose and fix the issue. This not only eliminates the unpleasant odor but, more importantly, neutralizes a significant safety hazard.

Taking the time to perform these checks and repairs will ensure your machine operates reliably and safely. A well-maintained snowblower is a dependable tool, ready to perform when the snow starts to fall, giving you peace of mind throughout the winter.