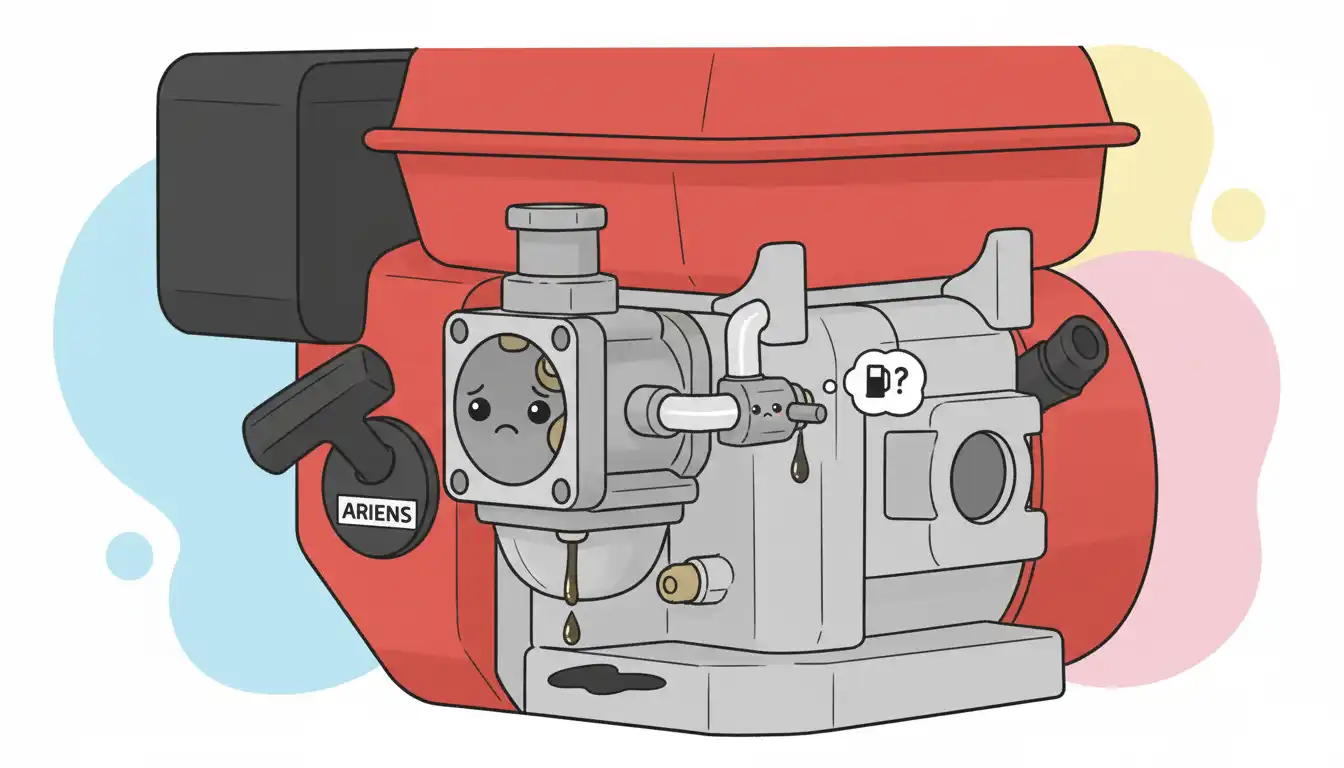

Ariens Carburetor Leaking Gas? Stop Leaks Fast (Valve Guide)

There are few things more frustrating than gearing up to clear a heavy snowfall only to find a puddle of gasoline under your powerful Ariens snow blower. That distinct smell of fuel is not just the sign of a wasted resource; it’s a significant safety hazard and a clear signal that your machine needs immediate attention. A gas leak, whether from the carburetor or the fuel shut-off valve, can stop your winter work dead in its tracks.

Fortunately, you’ve come to the right place. This guide will walk you through the common causes of fuel leaks on Ariens snow blowers and provide actionable, step-by-step solutions. We will cover everything from the intricate components inside your carburetor to the simple but crucial fuel shut-off valve, empowering you to diagnose and fix the problem safely and effectively.

You'll Learn About

Decoding the Drip: Why Your Ariens Snow Blower Leaks Gas

A gas leak on your Ariens snow blower almost always originates from one of two primary areas: the carburetor or the fuel shut-off valve. Understanding the role of each component is the first step toward a successful repair. These parts work together to deliver fuel to the engine, but over time, gaskets can degrade and parts can fail.

Modern gasoline itself can be a contributing factor. Most fuel available at the pump contains ethanol, which is known to be corrosive to rubber and plastic components found in small engines. Over time, ethanol can cause gaskets, seals, and fuel lines to become brittle and crack, leading to leaks that weren’t as common with older, ethanol-free gasoline.

The Carburetor: Ground Zero for Fuel Leaks

The carburetor is the heart of your snow blower’s fuel system, mixing gasoline with air to create a combustible mixture for the engine. It’s a complex component with several moving parts and seals, making it a common source of leaks. When fuel escapes from the carburetor, it’s typically due to an internal failure that causes the fuel bowl to overfill and overflow.

One of the most frequent culprits is a stuck float or a faulty needle valve. The float rises with the fuel level in the carburetor bowl, and when it reaches the correct level, it pushes a small needle into a seat to shut off the flow of gasoline. If the float gets stuck in the down position or the needle fails to seal properly, gasoline will continuously flood the carburetor and leak out.

Another common issue is a worn-out carburetor bowl gasket. This gasket creates a seal between the carburetor body and the fuel bowl at the bottom. With age and exposure to gasoline, especially ethanol-blended fuels, this rubber ring can dry out, crack, or become compressed, allowing fuel to seep out from the bottom of the carburetor.

The Fuel Shut-Off Valve: A Common But Overlooked Culprit

The fuel shut-off valve is a simple but vital component that allows you to stop the flow of gasoline from the tank to the carburetor. This is particularly useful for storage and maintenance. However, like any part with seals, it can become a source of leaks over time. A leak from this valve is often easier to spot, appearing directly below the valve itself where it connects to the fuel tank or the fuel line.

Leaks from the shut-off valve are typically caused by degraded internal seals or cracks in the valve body. The constant vibration of the engine and the corrosive effects of fuel can cause the plastic or rubber components inside the valve to wear out. Additionally, the connections where the fuel line attaches can become loose or the fuel line itself may develop cracks near the connection point.

Finding the Source: A Step-by-Step Diagnostic Approach

Before you can fix the leak, you must accurately identify its origin. Guessing can lead to unnecessary repairs and frustration. Follow these steps to pinpoint exactly where the gas is coming from. Safety is paramount: perform these checks in a well-ventilated area, away from any open flames or sources of sparks, and have a fire extinguisher nearby.

First, thoroughly clean and dry the engine area around the carburetor and fuel tank. Old oil, dirt, and grime can obscure the true source of a fresh leak. Once the area is clean, turn the fuel shut-off valve to the “On” position to allow gasoline to flow and carefully observe where the fresh fuel begins to appear. You may need to use a flashlight to get a clear view. Trace the path of the fuel from the highest wet point downwards to find the source.

If the leak is coming from the body of the carburetor, particularly from the seam where the bowl attaches, the issue is likely internal. If you see fuel dripping directly from the fuel shut-off valve or the attached fuel line, you have found your culprit. Sometimes, a leak may only appear when the engine is running due to vibration, so if you can’t find it while static, you may need to briefly and safely run the engine while observing.

Fixing a Leaky Ariens Carburetor: Your Action Plan

Once you’ve confirmed the carburetor is the source of the leak, it’s time to take action. The most common fixes involve addressing the float and needle assembly or replacing the bowl gasket. These are tasks that can be accomplished with basic hand tools.

Solution 1: Addressing a Stuck Float and Faulty Needle

A stuck float is a very common reason for a carburetor to overflow and leak gas. Sometimes, a quick, temporary fix can be achieved by gently tapping the side of the carburetor bowl with the plastic handle of a screwdriver. This vibration can sometimes be enough to free a sticky float and allow the needle valve to seat properly, stopping the leak.

For a more permanent solution, you will need to remove and clean the carburetor bowl. First, ensure the fuel shut-off valve is closed and place a small container underneath to catch any spilled gas. The bowl is typically held in place by a single bolt at its base. Once removed, you can carefully lower the bowl, taking care not to spill the gasoline inside. Inspect the bowl for any sediment or debris that could be causing the float to stick.

With the bowl off, you will see the float assembly. Gently pivot the float up and down to ensure it moves freely. The needle valve is often attached to the float with a small wire clip. You can remove the float by sliding out the pin that holds it in place. Carefully inspect the rubber tip of the needle for any signs of wear, deformation, or debris that would prevent it from creating a perfect seal. Clean the needle and the seat it goes into with carburetor cleaner and a soft cloth before reassembly.

Solution 2: Replacing a Worn Carburetor Bowl Gasket

If the leak is clearly seeping from the seam between the carburetor body and the bowl, the bowl gasket is almost certainly the problem. This is a straightforward and inexpensive repair. After removing the carburetor bowl as described above, you will see the old gasket, which is a simple O-ring seated in a groove on the carburetor body or the top edge of the bowl.

Use a small pick or screwdriver to carefully remove the old gasket. Be mindful not to scratch the metal surfaces. Before installing the new gasket, clean the groove and the corresponding mating surface on the bowl thoroughly to ensure a clean seal. A new gasket should fit snugly into the groove, creating a tight seal when the bowl is reinstalled and tightened.

How to Repair a Leaking Ariens Fuel Shut-Off Valve

If your diagnostic work points to the fuel shut-off valve, the repair is typically a simple replacement. These valves are generally not serviceable and are inexpensive to replace. Fixing this promptly is critical to prevent fuel from leaking when the machine is not in use.

The first and most critical step is to drain the fuel tank completely. Once the tank is empty, you can proceed to remove the valve. Place a rag or container under the valve to catch any residual fuel. Use pliers to slide the hose clamp up the fuel line, then carefully twist and pull the fuel line off the valve’s outlet nozzle.

The valve itself is usually threaded into the bottom of the fuel tank with a nut securing it. Hold the valve to keep it from turning and loosen the retaining nut. Once the nut is loose, you can unscrew the valve from the tank. Installation of the new valve is the reverse of removal. Ensure the new valve has its rubber gasket in place to create a seal against the tank, then tighten the retaining nut until it is snug. Do not overtighten. Reattach the fuel line and secure it with the clamp.

Preventative Maintenance: Your Best Defense Against Leaks

The best way to fix a leak is to prevent it from ever happening. A consistent maintenance schedule is key to the longevity and reliability of your Ariens snow blower. Simple, proactive steps can save you from the headache of a fuel leak on a snowy day.

One of the most important preventative measures is proper fuel management. Always use fresh gasoline (less than 30 days old) and add a quality fuel stabilizer, especially if you buy more fuel than you will use in a month. Stabilizer prevents the fuel from breaking down and forming gummy deposits that can clog carburetor passages and cause the float needle to stick. For long-term storage, it’s best to run the engine until the carburetor is empty, which prevents fuel from evaporating and leaving varnish in the bowl.

Regular inspections of your fuel system components are also crucial. Periodically check the fuel lines for any signs of cracking or brittleness and replace them if they appear worn. Ensure all clamps are tight and that the fuel shut-off valve operates smoothly. Addressing a small issue, like a worn fuel line, before it fails can prevent a much larger problem. To help identify the correct parts for your machine, you might need to know its age, which you can find out with a guide on determining what year your Ariens snowblower is. While you’re inspecting for fuel leaks, it’s also a good idea to check for other potential issues, such as if your Ariens snowblower is leaking oil.

Seasonal Maintenance Checklist

A structured maintenance plan can keep your machine in top condition. This table outlines a simple schedule for tasks related to preventing fuel leaks and ensuring overall reliability. A well-maintained machine is less likely to experience sudden failures, including fuel system problems that can lead to no-start situations, a common issue discussed in the Ariens EFI snowblower won’t start guide.

| Timing | Maintenance Task | Purpose |

|---|---|---|

| Before Each Use | Inspect fuel lines for cracks or brittleness. | Prevents unexpected line failure and leaks during operation. |

| Monthly (During Season) | Check fuel for freshness; add stabilizer if needed. | Prevents fuel degradation that clogs carburetors. |

| Annually (Pre-Season) | Inspect carburetor bowl gasket for signs of drying or cracking. | Catches a potential leak point before it fails. |

| Annually (Pre-Season) | Operate the fuel shut-off valve to ensure it moves freely. | Ensures the valve is not seizing and is sealing properly. |

| End of Season (Storage) | Run engine with fuel valve off to empty the carburetor. | Prevents varnish buildup from evaporated fuel causing stuck floats. |

When It’s Time to Call a Professional

While many fuel leak repairs are manageable for a DIYer, there are situations where calling a qualified small engine mechanic is the wisest and safest choice. If you have performed the steps in this guide and the leak persists, there may be a more complex issue at play. For instance, the carburetor body itself could have a hairline crack that is difficult to see.

If you are not comfortable working with gasoline or disassembling the carburetor, it is always best to defer to a professional. A mechanic will have the tools and experience to diagnose the problem quickly and safely. They can also perform a comprehensive service to ensure the rest of your snow blower is in excellent working order for the winter ahead.

Your Ariens, Ready for the Storm

A fuel leak from your Ariens snow blower’s carburetor or shut-off valve can be an alarming discovery, but it doesn’t have to mean a costly repair or the end of your machine’s service life. By systematically diagnosing the source of the leak and following the clear, actionable steps outlined in this guide, you can confidently tackle the most common causes of these leaks.

From freeing a stuck float and replacing a simple gasket to swapping out a faulty fuel valve, these repairs are within reach for most homeowners. Paired with a proactive maintenance routine focused on fuel quality and regular inspections, you can ensure your Ariens snow blower remains a reliable and safe machine, always ready to face the heaviest winter storms.