Proper Walk In Freezer Superheat – Everything You Need to Know

In order to maintain the efficiency and proper functioning of a walk-in freezer, it is important to have an appropriate level of superheat. Superheat refers to the temperature of refrigerant gas above its boiling point in a cooling system.

A low or high level can cause various problems for both coolers and freezers.

You'll Learn About

Superheat Basics

Superheat is the amount of heat that exists above boiling point in a vapor state, such as refrigerant gas. The additional heat added to vapor allows it to absorb more energy for efficient functioning.

What is Superheat?

Superheated refrigerant has high-temperature levels compared with normal saturation temperature at which evaporating takes place by absorbing latent heat from air circulated through them.

Why is It Important in a Walk-in Freezer?

Because slight temperature variations can dramatically affect the overall effectiveness of a cooling system, optimum working conditions are critical for efficiency and performance.

Low temperatures are widely used in walk-in freezers. As a result, insufficient superheats may cause compressor damage due to regular overloading or cooling issues because there will be insufficient suction pressure management.

How is Superheat Measured?

SuperHeat is a broad term for an analysis that involves transforming liquid material into flowing vapors while measuring and computing its total cooling force. When analyzing, it employs instruments such as thermometers, clamp-on ammeters, sub-cooling analyzers, and so on, with readouts providing accurate measurement values.

Furthermore, according to Service Manuals Guidelines, Installation Companies often measure required SuperHeats depending on distinct models in specific circumstances and places.

As we learnt, the minimal value that should exist at Compressor Inlet Levels Ready To Start Operations Depending On Different Configurations/Offers. As a result, proper measures can be provided based on the many models available and selected.

Which is best for offerrings/market demands in specific circumstances? Regions that provide optimal efficiency inside systems if well maintained over time. Following the above-mentioned analytical procedures ensures effectiveness and prevents energy loss.

It damages equipment over time due to either over or underloading, resulting in significant production costs.

Why is Minimum Superheat Required?

In refrigeration systems, it is essential to maintain a minimum superheat at the compressor to ensure its proper operation and prevent damage due to overheating.

Superheat refers to the temperature difference between the vapor leaving an evaporator and the boiling point of that refrigerant under existing conditions.

Why is Minimum Superheat Required?

Minimum superheat refers to the amount of heat added back into the refrigerant vapor after it has left an evaporator before entering a compressor’s suction line.

Consequences of Insufficient Superheats

Insufficient levels can lead to major problems in…

- Compressor operation: A high-volume flow may produce liquid slugging or even complete flooding (the compressor should only be confronted by gas), putting pressure on its components and potentially causing wear and tear over time.

- Poor System Efficiency: Without appropriate levels of energy existing within our system’s pipes, less energy from external sources such as ambient air cannot be dissipated efficiently, causing your unit to work hard merely to produce the minimum amount of output expected.

How to Ensure Minimum Superheater at the Compresor?

One method to mitigate these hazards is to maintain optimal ranges through careful measuring techniques and stringent control mechanisms. Because measuring equipment keep them informed whether values move significantly above/below set limiting tolerances, operators may be aware when things go awry.

Digital thermometers must be utilized as measuring devices since they provide precise measurements with faster reaction times. During maintenance checks, a digital thermometer probe is fastened into pipelines.

While regularly scheduled services will aid in the early detection of any performance concerns. It warns us about abnormal fluctuations displaying emerging indicators requiring advanced attention before we reach the danger zone.

Proper maintenance procedures outlined above helps establish operating efficiencies protect equipment integrity throughout its lifecycle. It helps promoting lasting usefulness beyond shortest service lifetime projections issued would also increase untimely expenses avoided altogether if done correctly.

Superheat Requirements for Walk-in Freezers

Superheat Requirements for Hvac Systems

Superheat is the temperature of refrigerant vapor above its boiling point at a certain pressure. The ideal amount of superheat varies depending on the specific application and type of system being used.

Minimum Superheat Requirement

A minimum superheat requirement of 20°F is necessary to ensure that there is no liquid refrigerant entering into the compressor, which can cause damage or failure.

Superheat Requirements for Coolers Vs. Freezers

Evaporator superheats vary between coolers and freezers due to differences in thermal loads, typically ranging from 6-10 degrees Fahrenheit for coolers and 4-8 degrees Fahrenheit for freezers.

Ideal Superheat Requirement

For walk-in freezers an ideal evaporator super heat range should be implemented around -30°C (-22°F)to -26°C(-14°F). Moreover; it depends also depend upon indoor humidity level as well as outdoor weather conditions.

Cooler Vs. Freezer Cooling Requirements Comparison

Coolers have a higher relative humidity than freezers and are used for more healthy applications such as fruit and vegetable preservation. Similarly, if the chill display cabinets are depleted, it may be difficult to locate fresh soft drink cans.

When moist air enters the Walkin-Cooler, it becomes uncomfortable due to exudation against your shirt. However, devices that operate after reaching a predetermined cooler/freeze temperature emit ‘hot gas’ during the chilling operation, regardless of the ambient climate conditions.

The Importance of Proper Synthesis Before Use

Plant energy efficiency is ensured by maintaining proper levels of subcooling and superb according to manufacturer specifications. As a result, it is not affected by improper time, which leads to ongoing headache maintenance difficulties or higher electricity bills, making good anti-Wastage installation necessary.

How to Measure Superheat in a Walk-in Freezer?

Tools and Equipment Needed to Measure Superheat

To measure the superheat in a walk-in freezer, you will need:

- A digital thermometer for measuring suction line temperature.

- Gauge manifold set which includes hoses with high side and low side fittings, compound gauge, and refrigerant tank connectors.

- Refrigeration pressure/temperature chart specific to your refrigerant type.

Step-by-step Instructions for Measuring Superheat

Here are the steps for measuring superheat in a walk-in freezer:

- To begin, run the refrigerator normally until it reaches its steady-state operating condition.

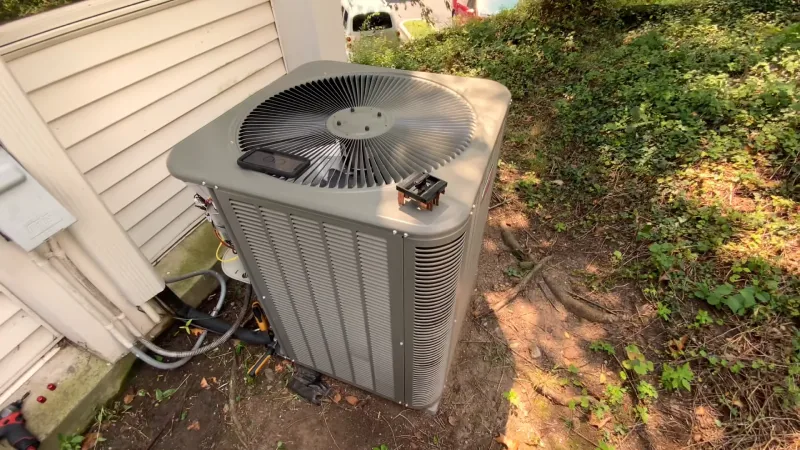

- The next step is to locate your suction line on the compressor’s outside unit of Your premises or installation place and label it with a marker pen. In order to avoid confusion, unless otherwise indicated elsewhere.

- Take note of both the internal air (return air near the evaporator inlet louvers/bars, for example) and the outdoor circumstances. (Ambient Temperature).

- Connect one end of each hose from the gauge manifold to the valve at the outside compressor unit.(Suction And Liquid Line valves-use screwdriver if necessary).

- Let’s connect some more ends out there, like the charging cylinder.(referigerantonwala,cylinderman or Whoever stored liquid ref around has connections that can make use available)

- Open the high side water valve on the manifold set, then install this end onto charging cylinders or any other low-precision source available. That is the percentage of supplied refrigerant volume.(In Reference To Tank Capacity). Then You’d Be Able To Enter Data Into The Digital Thermometer You Originally Used-Or Just Record Over The Temp/Psi Chart Reading (The One Provided By Mfgr/Others Printed Out W/Chart Pasted Somewhere)?

- Excess gas should be vented until the analog (gauge reading) stabilizes. That Might Do)-Perhaps a 5cm3 charge and then close the High Side Valve.

- Now, take your digital thermometer and pressure gauge and record the suction gas line temperature (Ts), high-pressure discharge side of the compressor temperature (Condenser/liquid AKA SH=0°), and pressure gauge temperature.(Tc).

Troubleshooting Common Issues When Measuring Superheat

Common Issues may include:

- If the superheat measurement findings deviate from the specified levels, check for refrigerant charge or valve functioning issues.

- If you are dissatisfied with your digital thermometer, you should replace it with one with a greater resolution.(rather than loss altogether).

- Low refrigerant levels could generate false readings.Low refrigerant charge causes the compressor to work harder than usual, causing the suction lines to overheat. As a result, there are unbalanced/inappropriate perceptible temperature differences->Gas escapes somewhere? The Vapor Compression Unit is broken and needs to be repaired as soon as possible.

- Something had been disconnected (someone had interfered?) to prevent correct operation.Critical Leaks/Lost Refrigerants as a result of Joint Connection Failure, etc.

Common Causes of High or Low Superheat

Superheat is a crucial factor in refrigeration systems that controls the temperature and pressure of refrigerants. It measures the amount of heat added to vapor from its boiling point at a particular pressure, indicating how well the evaporator coil transfers heat between refrigerant and air.

Minimum Superheat Requirements

One of the primary requirements for ensuring proper functioning of compressor components is maintaining a minimum superheat level. Typically, it should be around 20°F.

This ensures that there is no liquid carryover into compressors as low superheats can cause rapid wear on compressor parts by causing internal flooding or slugging return liquids.

Evaporator Superheat Ranges

Evaporators offer varying levels based on specific cooling purposes such as coolers (6-10 degrees) or freezers (4-8 degrees). If system control wants ice-forming ability—a lower range in both types will usually suffice—but if used for food preservation under different conditions—higher ranges are required.

Common Causes of High/low Superheats:

There could be various reasons behind high/low superheating levels within their respective optimal values;

- Faulty Expansion Valve: The expansion valve adjusts supply rates according to demand across an enclosed space. Hence allows sufficient coldness during expansion but malfunctioning valves remain open longer than necessary increasing supply rates beyond recommended(superhigh).

- Refrigerant Overcharge Or Undercharge: Refrigerant overflows inside coils which results In very reduced evaporation reducing process capacity. This promotes resulting in poor performance with overloaded substances. While low charge causes insufficient lubrication affecting overall operation processes leading often times zero performances due to Lubrication problems.

- Dirty Evaporator Coil: Another major source lies dirty condenser fins which frequently reduce normal flow. Because many impurities always block fluid channels ranging from dust particles, microbes settling along passage ways. It causes impacting negatively regarding operational abilities through effectiveness reduction creating issues again like those listed above.

Superheating concerns require careful attention since operating outside optimal values can cause issues such as high energy consumption, fluctuating cooling output.

Such concerns must approach with caution and proper remedies where necessary to ensure systems operate at recommended best performances.

What Causes High Superheat on a Walk in Freezer?

Insufficient Refrigerant

Low refrigerant levels prevent proper heat transfer causing the evaporator coil to become too hot.

Dirty Coils

Dirt, debris and other contaminants on coils reduce its efficiency in absorbing heat from gaseous refrigerants increasing superheat values.

Restricted Liquid Line

A clogged liquid line reduces the pressure difference between high-side discharge and low-side suction leading to increased superheat condition.

Poor Thermal Insulation

Leakages in door seals or walls of freezers allow warm air into space reducing cooling effectiveness resulting in higher than normal temperature differences between saturated vapor evaporation temperatures at inlet and outlet points thereby increasing superheating values.

Overload Systems

Walking freezer systems have a rating for maximum input power beyond which they are prone to malfunction. It’s due inadequate cooling capacity lowering saturation pressures further elevating discharged gas temperature via compressor overloading operations affecting by increaseing superheats.

What is Normal Superheat for 404a Refrigerant?

The normal superheat temperature for 404a refrigerant is 4-6 degrees. It’s a solid rule of thumb for keeping refrigeration systems running smoothly. The temperature rise in refrigerant above its boiling point is referred to as superheat.

The appropriate amount of superheat guarantees that all liquid has evaporated, leaving only gas to enter compressors. Due to insufficient suction pressure on intake ports, high quantities of superheat can cause compressor damage by overheating it.

Low levels may cause too much liquid to accumulate in the suction line and flood back into the compressor, causing slugging issues. Normal superheat values are affected by factors such as ambient temperature, load circumstances, and airflow.

Manufacturers provide unique guidelines based on equipment needs. Variable depending on system design considerations such as TXV changes or replacement cycle times.

Before adjusting or replacing refrigerants, follow the manufacturer’s recommendations. Sometimes ACs make noise in the sinks.

What is Normal Superheat for Freezer?

Normal superheat for freezers ranges from 4-8 degrees. Superheat refers to the temperature rise above refrigerant vapor saturation point. It is measured at the outlet of the evaporator in a freezer system.

Normal superheat prevents liquid refrigerants from entering the compressor, causing damage and failure. When there is insufficient or no superheat, it implies a lack of heat load on the evaporator coil.

When cold air does not transmit enough heat into the room/space being cooled. Excessive superheat values may also indicate expansion valve performance issues or clogging/dirt accumulation in capillary tubes/filters.

The typical amount required varies depending on the kind and size of device. Because Chest freezers rarely self-defrost, they have a different typical quantity than uprights/freezer/fridge combos.

As a result, more frequent checks for ice buildup/organs probable defect-i.e. the thermostat/compressor cycle having faults that can lead to insufficient cooling-are required.

It’s even with adequate freon/coolant levels. Checking on a frequent basis to ensure constant freezing temperatures that keep your frozen items safe for ingestion is part of proper maintenance.

Failure to do so reduces appliance lifespan while increasing energy consumption.

To Recap

By ensuring that evaporator superheat levels are within the recommended range (4-8 degrees) for freezers, one can avoid issues such as compressor damage or insufficient cooling capacity.

It is crucial that businesses regularly measure and monitor their walk-in freezer’s superheat levels to keep them running smoothly and effectively over time.