Splice 10/3 Wire [is Easy to Do]

Splicing electrical wires is a common task in many home improvement and repair projects. It is important to splice wires safely to prevent accidents and ensure that the electrical system is functioning properly.

10/3 wire, also known as 10 gauge wire, is a type of wire commonly used in electrical systems. It is often used for heavy-duty appliances, such as electric dryers and ranges, and for circuits that require high amounts of power.

In this guide, we will discuss the proper steps and materials needed to splice 10/3 wire safely and effectively.

You'll Learn About

How to Splice 10/3 Wire?

To splice 10/3 wire, you will need to follow a few steps:

- First, turn off the power to the circuit you will be working on. Use a voltage tester to confirm that there is no electricity flowing through the wires.

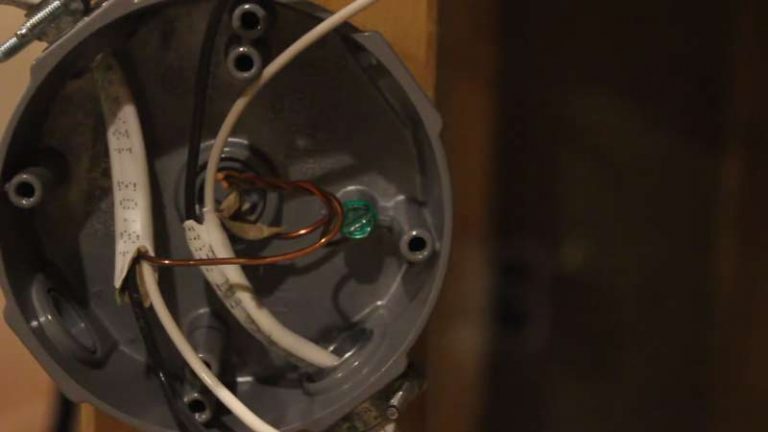

- Next, locate the point where you will be splicing the 10/3 wire. It is important to use a junction box at this point to protect the splice and ensure that it remains accessible. Choose a junction box that is large enough to accommodate the 10/3 wire and any other wires that may be present in the box.

- Cut the 10/3 wire at the splice point using wire strippers or wire cutters. Strip about 1 inch of insulation off the end of each wire.

- Use wire connectors, also known as wire nuts, to join the two ends of the 10/3 wire together. Be sure to twist the wires together tightly and secure the wire nuts firmly.

- Once the splice is complete, wrap the entire splice in electrical tape to provide additional protection.

- Finally, attach the junction box cover and restore power to the circuit.

It is important to follow these steps carefully and to use the appropriate tools and materials to ensure that the splice is safe and secure. If you are unsure about how to splice 10/3 wire, it is best to consult a licensed electrician or refer to the National Electrical Code for guidance.

Safety Precautions

It is crucial to take safety precautions when splicing electrical wires, as working with electricity can be dangerous. The first and most important step is to turn off the power to the circuit you will be working on.

This can usually be done by flipping the appropriate circuit breaker or unplugging the appliance. It is important to double-check that the power is off by using a voltage tester on the wires.

In addition to turning off the power, it is also important to wear proper safety gear when splicing electrical wires. This includes gloves to protect your hands, as well as goggles to protect your eyes from flying debris.

It is also a good idea to have a fire extinguisher nearby in case of any accidents. Following these safety precautions will help to ensure that you can splice the 10/3 wire safely and without any mishaps.

Materials and Tools Needed

In order to splice 10/3 wire, you will need to have the following materials and tools on hand:

Junction Box

A junction box is a device used to protect and contain electrical connections. It is important to use a junction box when splicing 10/3 wire to ensure that the splice remains accessible and protected. Choose a junction box that is large enough to accommodate the 10/3 wire and any other wires that may be present in the box.

Wire Strippers or Wire Cutters

These tools are used to cut the 10/3 wire at the splice point. Wire strippers have a built-in wire cutter and are used to strip the insulation off the ends of the wires. Wire cutters are simply used to cut the wire.

Wire Connectors (Wire Nuts)

Wire connectors, also known as wire nuts, are used to join the two ends of the 10/3 wire together. They come in various sizes to fit different gauges of wire. Be sure to choose the appropriate size for the 10/3 wire.

Electrical Tape

Electrical tape is used to wrap the splice and provide additional protection. It is important to use electrical tape that is specifically designed for use on electrical wires.

Having these materials and tools on hand will ensure that you are prepared to splice the 10/3 wire safely and effectively.

Step-by-step Guide to Splicing 10/3 Wire

To splice 10/3 wire, follow these steps:

Locate the Splice Point and Install a Junction Box

The first step is to locate the point where you will be splicing the 10/3 wire. It is important to use a junction box at this point to protect the splice and ensure that it remains accessible. Choose a junction box that is large enough to accommodate the 10/3 wire and any other wires that may be present in the box.

Install the junction box according to the manufacturer’s instructions.

Cut the 10/3 Wire at the Splice Point

Using wire strippers or wire cutters, cut the 10/3 wire at the splice point.

Strip the Insulation Off the Ends of the Wires

Using wire strippers, strip about 1 inch of insulation off the end of each wire.

Use Wire Connectors to Join the Two Ends of the Wire Together

Hold the two ends of the 10/3 wire together, and use wire connectors to secure them in place. Be sure to twist the wires together tightly and secure the wire connectors firmly.

Wrap the Splice in Electrical Tape

Once the splice is complete, wrap the entire splice in electrical tape to provide additional protection.

Attach the Junction Box Cover

Finally, attach the junction box cover to the junction box.

By following these steps, you can splice the 10/3 wire safely and effectively.

Tips and Considerations

Here are a few tips and considerations to keep in mind when splicing 10/3 wire:

Choosing the Right Size Junction Box

It is important to choose a junction box that is large enough to accommodate the 10/3 wire and any other wires that may be present in the box. A junction box that is too small may not provide enough room for the splice, while a junction box that is too large may be unnecessarily bulky and difficult to install.

Tightly twisting the wires together and securing the wire connectors firmly: It is important to twist the wires together tightly and secure the wire connectors firmly to ensure that the splice is strong and secure.

Following the National Electrical Code Guidelines for Splicing

The National Electrical Code (NEC) is a set of standards that outlines the proper way to install and maintain electrical systems. It is important to follow these guidelines when splicing 10/3 wire to ensure that the splice is safe and meets industry standards. If you are unsure about the NEC guidelines for splicing, it is a good idea to consult a licensed electrician or refer to the NEC for guidance.

By following these tips and considerations, you can splice the 10/3 wire safely and effectively.

Conclusion

Splicing 10/3 wire is an important task that requires careful attention to safety and proper technique. By following the steps outlined in this guide and using the appropriate materials and tools, you can splice the 10/3 wire safely and effectively.

However, if you are unsure about any part of the process, it is important to seek the help of a licensed electrician. Working with electricity can be dangerous, and it is always better to err on the side of caution.

Splicing 10/3 wire is a straightforward task if you follow the proper steps. Ensure you use the right connectors and tools, and always turn off the power before starting. Proper splicing ensures a safe and reliable electrical connection.

While working on your wiring, consider other electrical projects. For example, learning why there are two holes in plug prongs can enhance your understanding of electrical systems. Additionally, understanding the difference between duplex and regular outlets can help you make informed decisions about your home’s wiring. For more tips, explore our guide on checking if you’ve drilled through a wire.