Snowblower Surges With Choke Off? Here’s the 5-Minute Fix!

It’s a frustratingly common scenario for snowblower owners. You pull the starter cord, the engine fires up perfectly with the choke on, and it hums along smoothly. But the moment you push the choke lever to the “off” or “run” position, the engine starts to hunt and surge, the RPMs pulsing up and down like it can’t catch its breath. This isn’t just annoying; it’s a clear signal that your machine is starving for fuel.

This surging is a classic symptom of an engine running too lean. When the choke is on, it restricts airflow, creating a rich fuel mixture that a cold engine needs to start. When you turn the choke off, the carburetor is supposed to deliver a balanced mix of air and fuel, but if it can’t supply enough gas, the engine surges.

You'll Learn About

Why Your Snowblower Only Runs Smoothly With the Choke On

Understanding the role of the choke is the first step to diagnosing the problem. The choke plate is simply a valve that temporarily cuts down the air supply entering the carburetor. This forces the engine to draw in a higher concentration of fuel, which is essential for cold starts.

Once the engine warms up, it no longer needs this extra-rich mixture. Pushing the choke to the “off” position opens the airway for normal operation. If the engine begins to surge at this point, it’s telling you that the normal fuel delivery circuits are blocked and it isn’t getting the gasoline it needs to run steadily.

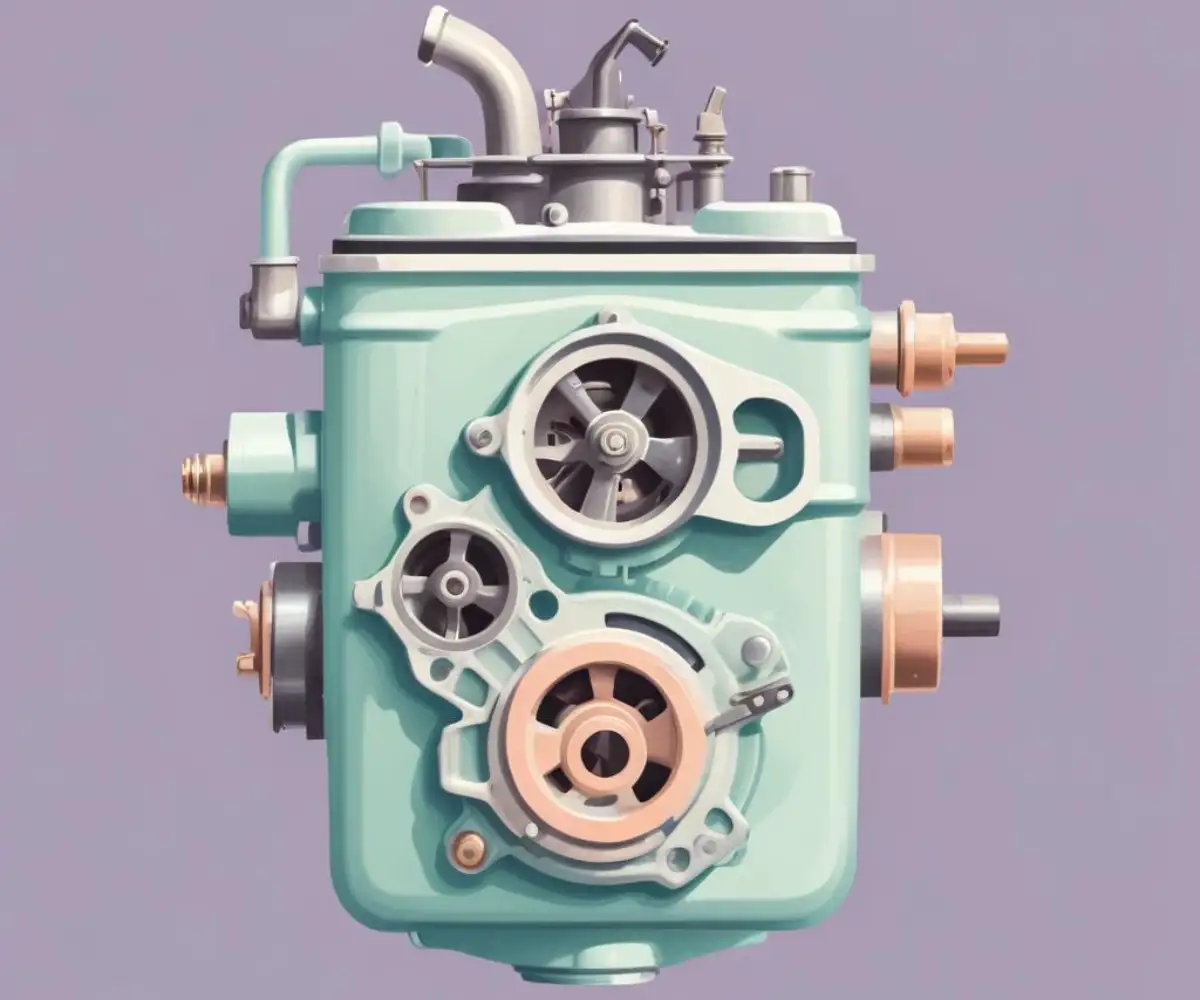

The #1 Culprit: A Clogged Carburetor

In the vast majority of cases, the root cause of a snowblower surging with the choke off is a dirty or clogged carburetor. This is especially true for machines that have been sitting for months with untreated fuel in the tank. Modern ethanol-blended gasoline can absorb moisture from the air, leading to corrosion and gummy deposits that wreak havoc on tiny internal passages.

These blockages most often occur in the carburetor’s main jet and pilot jet. The main jet is responsible for delivering fuel at high speeds, while the pilot jet handles the idle and low-speed circuits. Even a microscopic speck of debris in one of these critical passages can be enough to disrupt the fuel flow and cause the engine to run lean.

The Quick Fix: Cleaning the Carburetor Bowl and Jet

For a minor clog, you may be able to solve the surging issue without completely removing the carburetor. This process involves cleaning the main fuel jet, which is often integrated into the bolt that holds the carburetor’s fuel bowl in place.

First, position your snowblower on a level surface and shut off the fuel valve. Place a container underneath the carburetor to catch any spilled gasoline. Using a socket wrench, carefully unscrew the bowl nut at the bottom of the carburetor and remove the fuel bowl, taking care not to damage the rubber gasket.

Examine the bowl nut closely. It will have a large central hole and very small pinholes on the side. These tiny side holes are often the source of the blockage. Thoroughly spray the bowl and the nut with carburetor cleaner and use a thin wire—like one from a bread tie—to gently clear any debris from all the holes. Reassemble, turn the fuel back on, and test the engine.

The Deep Clean: A Full Carburetor Overhaul

If the quick clean doesn’t resolve the surging, a more thorough cleaning is necessary. This involves removing the carburetor from the engine for a complete disassembly and overhaul. Before you begin, take several photos of the carburetor’s connections, including the fuel lines and the governor linkages, to ensure you can reassemble it correctly.

Once removed, carefully disassemble the carburetor on a clean workbench. Remove the float, the needle valve, and all removable jets. Spray every passage and orifice with carburetor cleaner, followed by a blast of compressed air to ensure they are completely clear. This detailed cleaning is similar for most small engines, from a lightweight HS55 Honda snowblower to a more powerful machine.

Beyond the Carb: Other Potential Causes for Surging

While a dirty carburetor is the most frequent offender, other issues can also cause an engine to run lean and surge. If a thorough carb cleaning doesn’t solve the problem, it’s time to investigate these other potential causes.

Fuel System Issues

A problem with the fuel supply upstream of the carburetor can mimic the symptoms of a clogged jet. Old, stale fuel loses its volatile compounds, leading to poor combustion. Always start the season with fresh gasoline that is less than 30 days old.

Another often-overlooked component is the fuel cap. The fuel cap must have a vent to allow air to enter the tank as fuel is consumed; otherwise, a vacuum will form and restrict fuel flow. To check this, slightly loosen the cap while the engine is running. If the surging stops, the vent is clogged and the cap needs to be replaced.

Air Leaks and Gaskets

An engine can also run lean if there is a vacuum leak. This happens when air is sucked into the engine from somewhere other than the carburetor’s main intake. The most common sources of vacuum leaks are cracked or damaged gaskets between the carburetor and the engine block.

You can test for a leak by spraying a small amount of carburetor cleaner around the gasket mating surfaces while the engine is running. If the engine’s RPMs change, it indicates that the spray is being sucked in through a leak. Replacing the faulty gasket is the only solution.

The Governor System

The governor is a mechanical system designed to maintain a constant engine speed under different loads. If the governor’s springs or linkages are stretched, worn, or incorrectly adjusted, it can cause the engine to “hunt” for the correct RPM, resulting in surging. For those experiencing this, a Toro snowblower governor adjustment may be necessary, and the principles often apply to other brands as well.

Troubleshooting Summary: Surging Engine

Use this table as a quick reference to diagnose and address the most common causes of a snowblower that surges when the choke is off.

| Symptom | Most Likely Cause | Recommended Solution |

|---|---|---|

| Engine surges at high speed with choke off. | Clogged main jet in the carburetor. | Remove and thoroughly clean the carburetor’s main jet and emulsion tube. |

| Engine starts fine, then dies when choke is turned off. | Severe fuel starvation or blockage. | Check for a clogged fuel filter, pinched fuel line, or a blocked fuel cap vent. |

| Surging is erratic and worsens under load. | Governor system malfunction. | Inspect governor springs and linkages for damage or misadjustment. |

| Engine runs rough at all times, not just when choke is off. | Stale fuel or a vacuum leak. | Drain and replace the old fuel; check carburetor gaskets for air leaks. |

A Proactive Approach: How to Prevent Surging in the Future

The best way to deal with a surging snowblower is to prevent it from happening in the first place. Proper fuel management and routine maintenance are key. Always use a fuel stabilizer in your gas can to keep the fuel fresh and prevent the formation of varnish and gum.

At the end of the winter season, either drain the fuel system completely or run the snowblower until it is out of gas. This prevents old fuel from sitting in the carburetor and clogging the delicate jets and passages, ensuring your machine, whether it’s a small single-stage or a heavy-duty model like a Honda 828 snowblower, is ready to go after summer storage.

When to Call a Professional

While cleaning a carburetor is a manageable task for many DIYers, it’s not for everyone. If you’ve tried the basic steps and the engine still surges, or if you’re not comfortable completely disassembling the carburetor, it may be time to consult a qualified small engine mechanic.

A professional will have the right tools, including ultrasonic cleaners that can remove even the most stubborn deposits from a carburetor. They can also quickly diagnose less common problems, saving you time and frustration and getting you back to clearing snow safely and efficiently.