Hydro-gear Zt-3100 Problems and Solutions

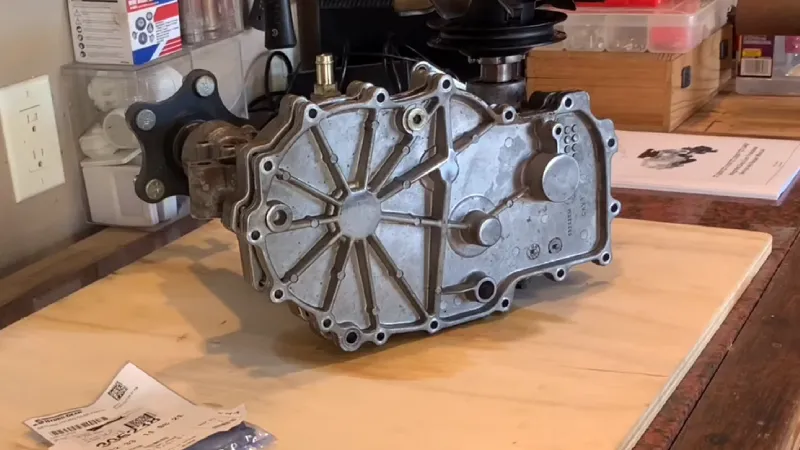

The Hydro-gear zt-3100 is a crucial component of many lawn mowers, providing the necessary power to propel the machine forward. However, despite its importance, this component is not without its share of problems.

Whether due to wear and tear, manufacturing defects, or other factors, issues with the Hydro-gear zt-3100 can cause serious problems for lawn mower owners. In this blog post, we’ll take a closer look at some of the common problems associated with the Hydro-gear zt-3100, as well as some potential solutions.

You'll Learn About

Common Problems With the Hydro-gear Zt-3100

The Hydro-gear zt-3100 is a highly regarded transmission system that is commonly used in commercial mowers and lawn tractors. However, like any mechanical system, it can suffer from a range of problems that may affect its performance and durability. In this article, we will discuss some of the common problems associated with the Hydro-gear zt-3100 and their potential causes and solutions.

Cavitation problem: One of the most common issues that can occur with the Hydro-gear zt-3100 is cavitation. Cavitation is defined as the formation of air bubbles in the hydraulic fluid. These air bubbles can cause a significant reduction in the hydraulic pressure, which can lead to a range of issues such as noise, reduced performance, and even damage to the system.

Some of the common causes of cavitation include low fluid levels, contaminated fluid, or a malfunctioning hydraulic pump. To prevent cavitation, it is important to check the fluid levels regularly and replace the fluid if necessary. Low-pressure and high-pressure issues might be created.

Whining noise: Another common issue that users may encounter with the Hydro-gear zt-3100 is a whining noise. This noise can be caused by a range of factors, including damaged gears, low fluid levels, or worn bearings.

To diagnose the cause of the noise, it is important to carry out a thorough inspection of the system. If the noise is caused by damaged gears, the transmission may need to be replaced. If the noise is caused by low fluid levels, adding more fluid can help to reduce the noise.

Gear shift problem: Gear shift problems are another common issue that users may encounter with the Hydro-gear zt-3100. This can be caused by a range of factors, including low fluid levels, worn shift forks, or a malfunctioning shift linkage.

To fix this problem, it is important to check the fluid levels and replace the fluid if necessary. If the problem persists, inspecting the shift linkage and shift forks can help to identify the underlying cause.

Overheating: Finally, overheating is another issue that users may encounter with the Hydro-gear zt-3100. This can be caused by a range of factors, including low fluid levels, a malfunctioning fan, or a clogged hydraulic filter.

To prevent overheating, it is important to check the fluid levels regularly and replace the filter if necessary. It is also important to ensure that the cooling system is functioning correctly.

In conclusion, the Hydro-gear zt-3100 is a reliable transmission system that is commonly used in commercial mowers and lawn tractors. However, users may encounter a range of problems that can affect its performance and durability. By understanding the common problems and their potential causes and solutions, users can take steps to prevent or fix issues as they arise.

Common Hydro-gear zt-3100 Problems and Solutions

| Problem | Causes | Solutions |

|---|---|---|

| Cavitation | Low oil level or poor quality oil | Refill or replace oil with high-quality oil, check for leaks |

| Whining noise | Worn-out bearings or damaged gears | Replace damaged parts, lubricate gears, tighten loose connections |

| Gear shift problem | Damaged shift lever or linkage | Inspect and replace damaged parts, adjust linkage, lubricate |

| Overheating | Low oil level, dirty oil or damaged fan | Refill or replace oil, clean or replace the fan, check for leaks |

Prevention and Maintenance of Hydro-gear Zt-3100

Prevention and maintenance of the Hydro-gear zt-3100 is important to ensure its longevity and smooth operation. Here are some preventive measures and maintenance tips:

Regular Oil Change

The Hydro-gear zt-3100 requires regular oil changes to maintain its performance. The manufacturer recommends changing the oil after the first 50 hours of operation and then every 200 hours after that. Using the wrong type of oil or not changing the oil can lead to increased wear and tear on the transmission.

Proper Cleaning and Lubrication

Keeping the Hydro-gear zt-3100 clean and lubricated is essential for its proper functioning. Regular cleaning can prevent debris and dirt from getting inside the transmission and causing damage. Lubrication of moving parts can also help reduce friction and prevent wear and tear on the transmission.

Inspecting and Replacing Damaged Parts

Inspecting the Hydro-gear zt-3100 for damaged or worn parts is important to prevent further damage. Replacing any damaged or worn parts can help ensure the transmission operates correctly. Checking the transmission for damage during routine maintenance is recommended.

Proper Storage and Usage

Proper storage and usage of the Hydro-gear zt-3100 is essential to maintain its performance. The transmission should be stored in a dry location to prevent rust and corrosion. When using the transmission, avoid sudden starts and stops that can cause excessive wear and tear on the transmission.

In conclusion, proper maintenance and prevention can help keep the Hydro-gear zt-3100 running smoothly for years to come. Regular oil changes, proper cleaning and lubrication, inspecting and replacing damaged parts, and proper storage and usage are all essential to ensure the longevity and proper functioning of the Hydro-gear zt-3100. By following these tips, you can prevent transmission problems and save money in the long run.

Troubleshooting the Hydro-gear Zt-3100

Identifying the source of the problem:

When troubleshooting the Hydro-gear zt-3100, it is important to first identify the source of the problem. This can be achieved by carefully listening to any unusual noises, observing any unusual behavior of the machine, and checking for any leaks.

It is also important to check for any damaged or worn-out parts. Some common signs of problems with the Hydro-gear zt-3100 include a loss of power, difficulty in steering, and strange noises.

Steps to take in resolving the issue:

Once the source of the problem has been identified, the next step is to take the appropriate measures to resolve the issue. In some cases, a simple fix such as changing the oil or cleaning the machine can solve the problem.

If the problem is more serious, it may require replacing damaged or worn-out parts. It is important to refer to the manufacturer’s instructions to ensure that all replacement parts are compatible and installed correctly.

Common mistakes to avoid during troubleshooting:

One common mistake to avoid when troubleshooting the Hydro-gear zt-3100 is to ignore any unusual noises or behavior. These are often early warning signs of a more serious problem that can escalate if left unattended.

Another mistake is to use incorrect parts or fail to follow the manufacturer’s instructions when replacing damaged parts. This can cause further damage and may even result in a safety hazard.

In conclusion, troubleshooting the Hydro-gear zt-3100 requires careful attention to detail and adherence to the manufacturer’s instructions. By identifying the source of the problem, taking appropriate measures to resolve the issue, and avoiding common mistakes, users can ensure that their machine remains in good working order and performs at its best for years to come.

Some More Problems and Solutions

Sure, here are five additional questions and answers related to the Hydro-gear zt-3100:

How Does the Hydro-gear Zt-3100 Compare to Other Transmission Systems for Lawn Mowers?

The Hydro-gear zt-3100 is a popular transmission system for commercial and residential lawn mowers. It is known for its durability and smooth operation, but there are other options available. For example, the Tuff Torq K46 and K62 are two other popular hydrostatic transmission systems used in lawn mowers.

These systems are also known for their durability, but they may not be as smooth as the Hydro-gear zt-3100.

Can the Hydro-gear Zt-3100 Be Repaired if It is Damaged?

Yes, it is possible to repair a damaged Hydro-gear zt-3100, but the process may vary depending on the specific problem. In some cases, a damaged part may need to be replaced, while in other cases, the system may need to be completely disassembled and rebuilt. It is important to consult a professional for repairs to ensure that the system is restored to proper working condition.

Is It Possible to Upgrade a Lawn Mower’s Transmission System to a Hydro-gear Zt-3100?

Yes, it is possible to upgrade a lawn mower’s transmission system to a Hydro-gear zt-3100, but the process can be complex and expensive. It may involve replacing multiple parts and making modifications to the mower’s frame. In addition, the upgrade may not be compatible with all lawn mower models, so it is important to consult with a professional before attempting the upgrade.

Can the Hydro-gear Zt-3100 Be Used in Other Types of Vehicles or Equipment Besides Lawn Mowers?

The Hydro-gear zt-3100 is primarily designed for use in lawn mowers, but it can also be used in other types of equipment. For example, it is sometimes used in small tractors, snow blowers, and utility vehicles. However, it is important to ensure that the system is compatible with the specific equipment before attempting to use it.

How Long Does a Properly Maintained Hydro-gear Zt-3100 Typically Last?

A properly maintained Hydro-gear zt-3100 can last for several thousand hours of use. The specific lifespan can vary depending on factors such as the frequency of use, the terrain the mower is used on, and the quality of maintenance. Regular maintenance, including oil changes and inspections, can help extend the life of the system.

Additional Tips for Maintaining and Troubleshooting

here are some additional tips for maintaining and troubleshooting the Hydro-gear zt-3100:

Keep the System Cool

One of the main causes of problems with the Hydro-gear zt-3100 is overheating. To prevent this, it’s important to keep the system cool by avoiding excessive loads, maintaining proper fluid levels, and ensuring proper ventilation.

Check the Belt Tension

If you notice slipping or other issues with the system, it’s important to check the belt tension. If the belt is too loose or too tight, it can cause problems with the operation of the system.

Address Issues Promptly

If you notice any issues with the Hydro-gear zt-3100, it’s important to address them promptly. Small issues can quickly turn into major problems if left untreated, so it’s better to deal with them early on.

Follow the Manufacturer’s Recommendations

To ensure the best possible performance and longevity from your Hydro-gear zt-3100, it’s important to follow the manufacturer’s recommendations for maintenance, usage, and storage. This can help prevent many common problems and extend the life of the system.

Consider Upgrading or Replacing the System

If you’re experiencing frequent problems or find that the Hydro-gear zt-3100 is no longer meeting your needs, it may be time to consider upgrading or replacing the system. This can help you avoid ongoing maintenance and repair costs, and ensure that your equipment is always operating at peak efficiency.

By following these tips and recommendations, you can help ensure that your Hydro-gear zt-3100 remains in top condition and continues to perform as it should.

Conclusion

The Hydro-gear zt-3100 is an essential component in many types of outdoor equipment. It is prone to various problems that can impede its performance and cause costly damages. These problems include cavitation, whining noise, gear shift issues, and overheating.

However, with proper maintenance, these problems can be prevented or resolved. Maintenance includes regular oil changes, proper cleaning and lubrication, inspecting and replacing damaged parts, and proper usage and storage.

When faced with a problem, troubleshooting should be carried out systematically, identifying the source of the issue and taking the necessary steps to resolve it while avoiding common mistakes. In summary, proper maintenance and prevention measures are critical to the longevity and performance of the Hydro-gear zt-3100, and recommendations include seeking professional help when necessary, keeping the manual handy, and avoiding DIY solutions that may cause further damage.