How to Seal Leaking Electrical Conduit: Simple Repair Guide

Discovering water inside your electrical conduit is a problem that demands immediate attention. It’s a silent threat that can lead to catastrophic failures, from short circuits to devastating electrical fires. Ignoring this issue is not an option, as it compromises the safety and integrity of your entire electrical system.

This comprehensive guide will walk you through exactly how to seal leaking electrical conduit, turning a potential disaster into a manageable task. We will explore the root causes, from environmental factors to installation oversights, and provide clear, actionable solutions. You’ll learn the professional techniques to create a lasting, watertight seal and protect your property.

You'll Learn About

Why Is Water in My Electrical Conduit? Uncovering the Culprits

Water intrusion in an electrical conduit isn’t just bad luck; it’s typically the result of specific environmental conditions or installation flaws. Understanding the source is the first critical step toward a permanent fix. Water can infiltrate these protective pathways in several ways, each requiring a specific approach to resolve.

From subtle temperature changes causing moisture buildup to direct leaks from groundwater, identifying the root cause is essential for effective sealing. Let’s break down the most common reasons you’re finding water where it doesn’t belong.

The Sneaky Threat of Condensation

One of the most common and often overlooked causes of water in conduit is condensation. This occurs when there’s a significant temperature difference between the inside and outside of the conduit run. Warm, moist air traveling through a conduit that passes into a colder area will cause moisture to condense and accumulate inside.

This is frequently seen in conduits that run from a heated basement or interior space to the outdoors or an unheated attic. The temperature gradient creates the perfect conditions for water vapor to turn into liquid, posing a serious threat to your wiring over time.

Groundwater and Rainwater Infiltration

Underground conduit runs are constantly at risk of water infiltration from the surrounding soil. Even the smallest crack, poorly sealed joint, or improper fitting can allow groundwater to seep in, especially in areas with a high water table or poor drainage. Hydrostatic pressure can force water through minuscule openings.

Similarly, above-ground outdoor conduits are exposed to rain. If fittings are not rated for wet locations or if seals have degraded over time due to UV exposure, rainwater can easily find its way inside. This is particularly true where conduit enters an electrical box or building penetration point.

Improperly Sealed Fittings and Entry Points

Every connection point, fitting, and entry into a junction box is a potential failure point. Using connectors that are not watertight, or failing to properly seal the threads and entry holes, is a direct invitation for moisture. Over time, gaskets can dry out and crack, and mechanical fittings can loosen.

It’s crucial that all components used in an outdoor or underground installation are specifically rated for those conditions. Often, a simple mechanical connection is not enough to form a permanent barrier against persistent water pressure.

The Dangers of Leaking Conduit: More Than Just a Puddle

Water and electricity are a notoriously dangerous combination. The presence of moisture inside your electrical conduit elevates the risk of severe electrical hazards and long-term damage that can be costly to repair. The consequences extend far beyond a simple tripped breaker.

Ignoring water in your conduit can lead to the degradation of your entire electrical system’s infrastructure. From corroded wires to the risk of electric shock, the dangers are real and significant.

Short Circuits and Fire Hazards

Water is an excellent conductor of electricity. When it comes into contact with live wires inside a conduit, it can create a path for electricity to flow between conductors or to the grounded metal conduit itself. This results in a short circuit, which can damage connected equipment and poses a significant fire risk.

Moisture compromises the insulation on wires, making them more susceptible to arcing and sparking. This is one of the leading causes of electrical fires, a hazard that proper sealing is designed to prevent.

Corrosion and System Degradation

When water sits inside a metal conduit, such as EMT or rigid steel, it will inevitably lead to rust and corrosion. This corrosion not only weakens the conduit itself but can also damage the wire insulation and the conductors within. Corroded connections lead to poor performance and eventual failure.

This degradation significantly reduces the lifespan of your electrical system. What should have lasted for decades might fail in just a few years, requiring extensive and expensive replacement work.

Your Step-by-Step Guide to Sealing Electrical Conduit

Now that you understand the causes and dangers, it’s time for the solution. Sealing a conduit effectively requires the right materials and a methodical approach. This process involves cleaning the area, choosing the appropriate sealant, and applying it correctly to create a durable, waterproof barrier.

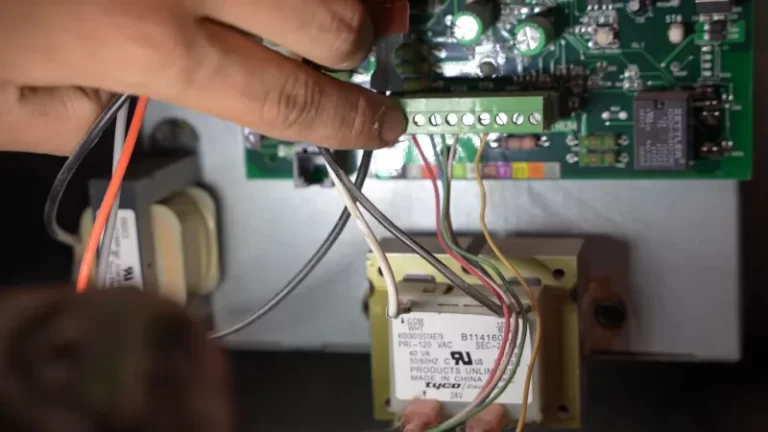

Safety is paramount. Before beginning any work, you must de-energize the circuit you’ll be working on. Turn off the corresponding breaker at your electrical panel and use a voltage tester to confirm there is no power to the wires inside the conduit.

Step 1: Inspect, Clean, and Dry the Conduit

Your first step is a thorough inspection to identify the exact points of water entry. Look for cracked fittings, loose connections, or gaps where the conduit enters a wall or box. Once you’ve found the problem areas, the conduit must be completely clean and dry before applying any sealant.

Use a cloth to wipe down the interior and exterior surfaces. For stubborn moisture inside, you can use a shop vacuum to pull air through the pipe or push a rag through with a fish tape. A clean, dry surface is essential for the sealant to adhere properly and form a lasting bond.

Step 2: Choose the Right Sealant

The type of sealant you use is critical to your success. Not all caulks or foams are created equal, and some are not suitable for electrical applications. Your choice will depend on the location of the leak and the size of the gap you need to fill. When considering materials for various home projects, understanding the specifications, like learning what is 3.25 od pvc pipe used for, can provide insight into choosing the right product for the job.

There are three primary types of sealants recommended for electrical conduits: duct seal putty, expanding foam, and silicone caulk. Each has its specific advantages and best-use scenarios.

Step 3: Apply the Sealant Correctly

Proper application is just as important as the sealant itself. For duct seal putty, you’ll want to work the material in your hands to make it pliable. Then, pack it firmly into the opening of the conduit and around the wires, ensuring there are no gaps or air pockets. It should form a dense, complete plug.

When using expanding foam, apply it carefully as it will grow to fill the space. A closed-cell foam is best for a watertight seal. For silicone caulk, apply a generous bead around the exterior of fittings or where the conduit enters a structure, smoothing it to ensure full coverage.

Comparing Your Conduit Sealing Options

With several effective sealing methods available, choosing the best one can be confusing. This table breaks down the most common options to help you decide which material is right for your specific situation. Consider factors like location, re-enterability, and the size of the opening you need to seal.

Each method has distinct pros and cons that make it more suitable for certain applications. Understanding these differences will ensure you create the most effective and durable seal possible.

| Sealing Method | Best For | Pros | Cons |

|---|---|---|---|

| Duct Seal Putty | Sealing conduit openings (indoors & outdoors) | Easy to apply, non-hardening, easily re-enterable | Not ideal for sealing joints or cracks, can sag over time |

| 2-Part Closed-Cell Foam | Sealing empty or occupied conduits against high water pressure | Creates a very strong, permanent, and watertight seal | More expensive, difficult to re-enter for future cable pulls |

| Silicone Caulk (Outdoor Rated) | Sealing exterior joints, fittings, and wall penetrations | Flexible, UV resistant, excellent adhesion | Can be difficult to apply inside conduit, some types corrode metal |

| Watertight Connectors/Hubs | Entry points into junction boxes and enclosures in wet locations | Engineered for a perfect seal, code-compliant | Requires replacing existing fittings, higher initial cost |

Preventing Future Leaks: Proactive Measures

Sealing an existing leak is only half the battle. The ultimate goal is to prevent water from ever entering your conduit again. This involves smart installation practices and regular maintenance to catch potential problems before they escalate.

A few proactive steps can save you significant time and money down the road. Sometimes, home maintenance issues can seem related, like when a fireplace mantel coming away from wall seems like a structural problem but might be caused by moisture, similar to conduit leaks.

Using Proper Fittings in Wet Locations

Always use fittings and connectors that are explicitly rated for “wet locations” when installing conduit outdoors or underground. These components, such as watertight hubs and raintight connectors, incorporate rubber gaskets or O-rings that create a much more reliable seal than standard fittings.

Ensuring every component of your conduit system is appropriate for its environment is the foundation of a leak-proof installation. Taking the time to select the right parts is a critical investment in the longevity and safety of your electrical system.

Addressing Condensation at the Source

To prevent condensation, you must stop the flow of air between warm and cold areas. The most effective way to do this is to seal both ends of the conduit run with duct seal putty. This creates an air trap, preventing moist air from moving into the colder section of the pipe and condensing.

Plugging the conduit openings inside electrical boxes and panels is a simple but highly effective preventative measure. This is a standard practice required by electrical codes in many situations to stop this exact problem.

Regular Inspection and Maintenance

Periodically inspect your outdoor and underground conduit systems. Look for signs of corrosion, cracked sealant, or physical damage. Catching a deteriorating seal early and reapplying caulk or putty is much easier than dealing with a conduit full of water.

Just as you might investigate the how much does a maytag water softener cost to manage your home’s water quality, investing time in maintaining your electrical system’s integrity is crucial for long-term safety and functionality. A small amount of proactive maintenance can prevent costly and dangerous failures.