Anchor in a Stud? Stop! The Ultimate Guide to Securely Hanging Anything

You’ve found the perfect spot for that new shelf, you’ve marked your hole, and you start to drill. You’re expecting the familiar soft give of drywall, but instead, your drill bites into solid wood. Congratulations, you’ve hit a stud! But wait—your plan was to use a wall anchor. Now what?

This scenario is incredibly common and springs from a fundamental misunderstanding of how walls are built and how hardware works. The simple truth is that hitting a stud is like striking gold for any DIY project. It’s the strongest point in your wall, and you should take full advantage of it.

Let’s clear up the confusion once and for all. This guide will walk you through why putting an anchor in a stud is a mistake, what to do if you’ve already drilled the wrong size hole, and the correct, secure way to mount heavy objects directly to a stud.

You'll Learn About

The Core Conflict: Understanding Anchors vs. Studs

Before we dive into the “how-to,” it’s crucial to understand the “why.” Your walls are not solid barriers; they are typically hollow structures consisting of drywall panels attached to a wooden or metal frame. The vertical beams of that frame are the studs.

A wall stud is the solid, structural support inside your wall. A drywall anchor is a device designed to expand in the hollow space behind the drywall, creating a secure point where there is no stud. The two are designed for completely opposite situations.

Therefore, the most important rule to remember is this: You should never intentionally put a standard wall anchor into a wood stud.

Why is an Anchor in a Stud a Bad Idea?

Wall anchors are engineered to function in a void. When you drive a screw into an anchor in drywall, it either expands, wings out, or toggles open behind the wall panel. This action braces it against the inside of the drywall, distributing the load over a wider area.

If you try to force an anchor into a solid wood stud, several problems arise. The anchor has no room to expand, which means it cannot function as designed. You end up with a weakened connection that relies on the friction of a plastic sleeve rather than the immense gripping power of a screw threaded directly into wood grain.

Worse, the act of drilling a large hole for the anchor removes significant material from the stud, potentially compromising its structural integrity for that specific point. You’ve created a bigger, weaker hole than necessary, defeating the purpose of finding the stud in the first place.

Help! I Already Drilled a Big Hole and Hit a Stud!

It’s a moment that causes many DIYers to panic. You’ve followed the instructions for a drywall anchor, drilled a 1/4-inch or even larger hole, and now you have a gaping opening in the stud that your intended screw will just slide into. Don’t worry, this is a fixable and very common problem.

First, put the wall anchor aside. You do not need it. Your goal now is to use the superior strength of the stud you’ve found. Here are the best solutions, from simplest to most robust.

Solution 1: Use a Thicker, Longer Screw

This is the easiest and often most effective fix. The hole you drilled for the anchor is now your pilot hole. Simply choose a wood screw or lag screw that is thicker in diameter than the hole you drilled. The new, larger threads will bite into fresh wood within the stud, creating a very strong connection.

Ensure the screw is also long enough. A good rule of thumb is that the screw should penetrate at least 1 to 1.5 inches into the stud itself. Add the thickness of your drywall (usually 1/2 inch) and the thickness of the item’s mounting bracket to determine the minimum screw length you need.

Solution 2: The Wooden Dowel Repair

If the hole is excessively large or you need to use the original screw that came with your item, the dowel method provides a rock-solid repair. This technique essentially fills the oversized hole with new wood, giving you a fresh surface to work with.

Start by finding a wooden dowel with the same diameter as the hole you drilled. Coat the dowel liberally with wood glue and tap it into the hole with a hammer until it’s flush with the stud. Once the glue has completely dried, you can cut the dowel flush with the drywall surface. You now have a solid wood plug in the stud, ready for you to drill a new, correctly-sized pilot hole for your original screw.

Solution 3: Shims or Wood Splinters (The Quick Fix)

For lighter-duty applications, a quick fix involves using wood glue and toothpicks or small wood shims. Fill the hole with a few glue-coated toothpicks or wood splinters, breaking them off flush with the surface. This added material will give the threads of your original screw something to bite into.

While effective for lighter items, this method is not recommended for anything particularly heavy. For substantial loads, the dowel repair or simply using a larger screw are far superior options.

The Right Way: How to Securely Mount Directly to a Stud

Now that we’ve covered the common mistakes and fixes, let’s focus on the correct procedure from the start. Mounting directly to a stud is the gold standard for hanging anything heavy and ensures the safety and security of your installation.

From shelving to large artwork, the process is straightforward when you follow these steps.

Step 1: Locate the Stud Accurately

The first step is finding the center of the stud. While tapping on the wall can give you a general idea, using an electronic stud finder is the most reliable method. Slide the stud finder horizontally across the wall until it beeps or flashes, indicating the edges of the stud. Mark both edges and measure to find the exact center.

Step 2: Drill a Pilot Hole

Once you’ve marked the center of the stud, it’s time to drill a pilot hole. A pilot hole is a small hole drilled before the main screw. This step is crucial as it prevents the wood stud from splitting when you drive in the larger screw and makes the screw much easier to install. The drill bit for the pilot hole should be slightly smaller than the diameter of the screw’s shank (the solid part without threads).

Step 3: Choose the Right Fastener

Forget the drywall anchors. For mounting into wood studs, you need wood screws or lag screws. The size and type depend entirely on the weight of the object you are hanging.

Drywall screws are not recommended for hanging heavy objects as they are brittle and can snap under shear stress. Opt for stronger structural or wood screws.

| Item Weight | Recommended Fastener | Minimum Stud Penetration | Pilot Hole Advice |

|---|---|---|---|

| Light (Under 20 lbs) – e.g., Small pictures | #8 or #10 Wood Screw | 1 inch | Use a bit slightly smaller than the screw shank. |

| Medium (20-50 lbs) – e.g., Shelves, large mirrors | #10 or #12 Wood Screw or 1/4″ Lag Screw | 1.5 inches | Essential to prevent splitting. Match bit to screw shank. |

| Heavy (50-100 lbs) – e.g., Small cabinets, TV mounts | 1/4″ or 5/16″ Lag Screw | 1.5 to 2 inches | Absolutely required. Drill to the depth of the screw. |

| Very Heavy (Over 100 lbs) – e.g., Large cabinets | 3/8″ Lag Screw or Multiple Fasteners | 2 to 2.5 inches | Use multiple studs for support whenever possible. |

Step 4: Drive the Screw

Using a drill or a socket wrench for lag screws, drive your chosen fastener through your item’s mounting bracket, through the drywall, and into the pilot hole in the stud. Drive the screw until the head is snug against the mounting surface, but be careful not to overtighten. Overtightening can strip the wood inside the stud, weakening the connection.

Advanced Considerations for Heavy Installations

Some projects require more than just a single screw in a stud. Understanding how to distribute weight and handle unique situations is key to a safe installation.

Hanging Extremely Heavy Objects

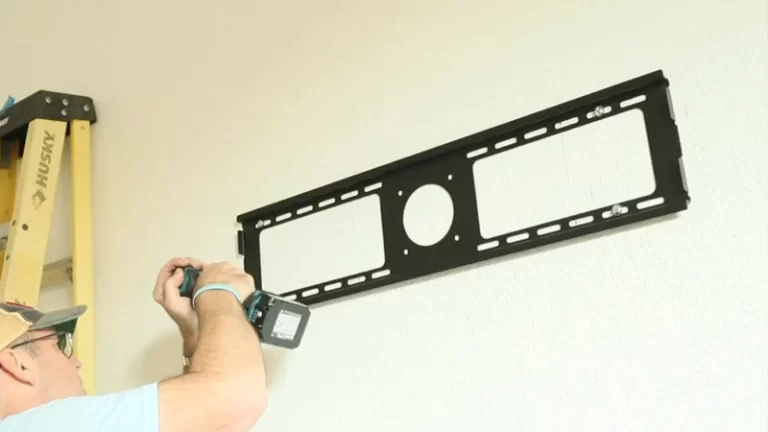

When hanging very heavy items like large cabinets or televisions, it’s best practice to span two or more studs. This distributes the load across a wider section of the wall frame. Learning how to secure a shelving unit to a wall properly often involves this multi-stud approach for maximum stability.

Specialty Projects: The Heavy Designer Mirror

Ornate, heavy mirrors often present a unique challenge due to their weight and value. The process for how to hang an Anthropologie mirror, for instance, is a perfect case study in why finding a stud is non-negotiable. For such items, using a heavy-duty lag screw or even a French cleat system secured to multiple studs is the safest method.

When You Can’t Use a Stud

Of course, sometimes a stud simply isn’t located where you need it. In these situations, and only for lighter to medium-weight items, a high-quality drywall anchor is the correct tool. Heavy-duty toggle bolts or snap-toggles are excellent choices for hollow walls as they provide a large bearing surface behind the drywall.

These scenarios can be tricky and require careful consideration of the wall material, similar to the challenges faced when you need to hang things on vertical siding, where finding a solid structural element is paramount.

Final Takeaways: Your Path to Secure Mounting

The confusion between wall anchors and studs leads to one of the most common DIY mistakes. By understanding their distinct purposes, you can avoid frustration and ensure your projects are safe and secure.

Remember the golden rules: Studs provide the ultimate support, and anchors are for hollow walls. Always use a pilot hole when driving a screw into a stud. And if you do make a mistake by drilling too large a hole, a simple fix with a larger screw or a wooden dowel will get you back on track.

Armed with this knowledge, you can confidently tackle any mounting project, knowing you’re using the right hardware for the job and creating a connection that will last for years to come.

![R-30 Insulation 2×8 [Everything You Need to Know]](https://fixitinthehome.com/wp-content/uploads/2023/01/R-30-Insulation-2x8-1-768x432.webp)