How Many Circuits in 1/2 EMT? [And Why?]

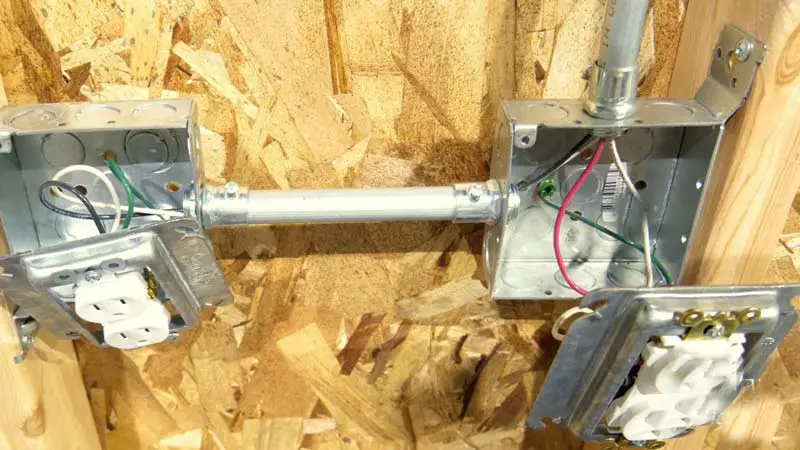

Installing electrical circuits in electrical metallic tubing (EMT) is an important part of many electrical projects. EMT is a type of conduit that is commonly used to protect and route electrical wiring in buildings and other structures.

It is made of thin-walled metal tubing that is coated with a protective layer to prevent corrosion. When installing electrical circuits in EMT, it is important to follow the National Electric Code (NEC) and consult with a licensed electrician to ensure that the installation is safe and compliant with the relevant codes and standards.

One key aspect to consider is the number of circuits that can be installed in a given size of EMT, such as 1/2 inch EMT. In this article, we will explore the factors that determine the number of circuits that can be installed in 1/2 inch EMT and provide examples based on the NEC guidelines.

You'll Learn About

How Many Circuits in 1/2 EMT?

In general, you can install 9 THHN #12 awg conductors in 1/2 inch EMT and 16 THHN #12 awg conductors in 3/4 inch EMT before you need to derate the circuit.

However, you should always follow the National Electric Code (NEC) and consult a licensed electrician for specific guidance on your project. The NEC provides detailed information on the types of wires and cables that can be used in electrical conduit and the maximum number of conductors that can be installed in a given size of conduit.

The maximum number of conductors allowed in a conduit is based on the size of the conductors and the size of the conduit, and it is limited to 40% fill of the cross-sectional area of the conduit.

THHN (thermoplastic high heat-resistant nylon-coated) wire is a common type of electrical wire used in building wiring and is suitable for use in electrical conduit.

It is an insulation material that has a higher temperature rating than THW (thermoplastic high heat-resistant wire). It is often used in residential and commercial buildings.

Factors That Determine The Number Of Circuits In EMT

The number of circuits that can be installed in EMT is determined by a combination of factors, including the size of the EMT, the size and type of the conductors, and the amount of current carried by the circuit. The size of the EMT refers to its diameter, which is typically measured in inches.

Diameter

In general, the larger the diameter of the EMT, the more conductors it can accommodate. However, the NEC sets limits on the maximum number of conductors that can be installed in a given size of EMT, regardless of its diameter.

Size

The size of the conductors, also known as their gauge, is another important factor to consider when determining the number of circuits in EMT. The gauge of a conductor refers to its thickness or cross-sectional area, which is usually measured in American Wire Gauge (AWG).

Cross-sectional Area

In general, larger gauge conductors have a larger cross-sectional area and can carry more current than smaller gauge conductors. The NEC provides tables that list the allowable ampacity of different sizes and types of conductors, which can be used to determine the maximum number of circuits that can be installed in EMT.

Amount of Current

The amount of current carried by the circuit is another factor that determines the number of circuits in EMT. The NEC specifies the maximum amperage that can be carried by different sizes of conductors and EMT, depending on the type of insulation used and the ambient temperature.

Safety

If the circuit carries more current than the maximum allowed by the NEC, the circuit must be derated to ensure safety. Derating involves reducing the maximum allowed current based on the number of conductors installed in the EMT, according to the rules set out in the NEC.

National Electric Code Guidelines For Circuit Installation In EMT

The National Electric Code (NEC) provides guidelines for installing electrical circuits in EMT and other types of conduit. One important resource for determining the number of circuits that can be installed in EMT is Table 310.16 of the NEC, which lists the allowable ampacity of different sizes and types of electrical conductors.

This table provides the maximum amount of current that can be safely carried by different sizes of conductors under different conditions, such as ambient temperature and type of insulation.

Another important guideline for circuit installation in EMT is the rule of 40% fill, which specifies the maximum number of conductors that can be installed in a given size of conduit. This rule states that the number of conductors installed in a conduit must not exceed 40% of the cross-sectional area of the conduit.

In other words, the conductors must not take up more than 40% of the space inside the conduit. This rule applies to EMT and other types of electrical conduit, and it is intended to ensure that the conductors have sufficient space to cool and prevent overheating.

To determine the maximum number of circuits that can be installed in EMT, you can use Table 310.16 to determine the allowable ampacity of the conductors, and then use the rule of 40% fill to calculate the maximum number of conductors allowed in the EMT based on its size.

It is important to follow these guidelines and consult with a licensed electrician to ensure that the electrical installation is safe and compliant with the NEC.

Examples Of Circuit Installation In 1/2 Inch EMT

Here are two examples of circuit installation in 1/2 inch EMT using THHN (thermoplastic high heat-resistant nylon-coated) conductors:

Example 1

12 awg THHN conductors According to Table 310.16 of the National Electric Code (NEC), the allowable ampacity of 12 awg THHN conductors is 30 amps in a conduit with an ambient temperature of 86°F (30°C) or lower.

This means that each 12 awg THHN conductor can safely carry up to 30 amps of current in 1/2 inch EMT. Based on the rule of 40% fill, the maximum number of conductors that can be installed in 1/2 inch EMT is 9, assuming that the conductors are spaced evenly and do not touch each other.

Therefore, you can install up to 9 12 awg THHN conductors in 1/2 inch EMT before you need to derate the circuit to ensure safety.

Example 2

14 awg THHN conductors According to Table 310.16 of the NEC, the allowable ampacity of 14 awg THHN conductors is 15 amps in a conduit with an ambient temperature of 86°F (30°C) or lower. This means that each 14 awg THHN conductor can safely carry up to 15 amps of current in 1/2 inch EMT.

Based on the rule of 40% fill, the maximum number of conductors that can be installed in 1/2 inch EMT is 16, assuming that the conductors are spaced evenly and do not touch each other. Therefore, you can install up to 16 14 awg THHN conductors in 1/2 inch EMT before you need to derate the circuit to ensure safety.

It is important to note that these examples are based on the NEC guidelines and assume that the conductors are spaced evenly and do not touch each other. In practice, you may need to install the conductors in a different configuration.

You may need to consider additional factors, such as the length of the circuit or the ambient temperature. In such cases, you may need to consult with a licensed electrician and follow additional guidelines to ensure the safety and compliance of the electrical installation.

Why 9 Circuits in 1/2 EMT?

According to the NEC Code, Condict Size, Ampacity derating, THWN/THHN wires, Safety concerts 9 circuits in ½ EMT is okay. Anyone should follow the rules in order to have the safe operation of any system using the wires.

NEC Code

The National Electric Code (NEC) is a set of regulations and guidelines that govern the installation and maintenance of electrical systems. These codes are designed to ensure the safety of electrical systems and the people who use them.

Conduit Size

The NEC sets limitations on the number of conductors that can be installed in a given size of conduit. For example, the code specifies that a maximum of 9 conductors can be installed in 1/2 inch EMT conduit.

This is because as the number of conductors in a conduit increases, the heat generated by the electrical current flowing through the conductors also increases. Larger conduit is required to accommodate more conductors and dissipate the heat generated.

Ampacity Derating

The ampacity of a conductor is the amount of electrical current that it can safely carry. As the number of conductors in a conduit increases, the ampacity of each individual conductor must be derated, or reduced, to prevent overheating and potential fire hazards.

THWN/THHN Wire

THWN and THHN are types of electrical wire that are commonly used in conduit systems. These wires are made of copper or aluminum and are rated for use in wet or dry locations.

They are also suitable for use in conduit systems, and must comply with the NEC code’s limitations on the number of conductors that can be installed in a given size of conduit.

Safety

The NEC codes and regulations are designed to ensure the safety of electrical systems and the people who use them. By limiting the number of conductors in a conduit and requiring ampacity derating, the NEC helps to prevent overheating and potential fire hazards.

It also ensures that the electrical system is able to handle the loads that are placed on it, and that it is able to dissipate the heat generated by the electrical current flowing through the conductors.

Why the Right Wire Size is Important?

Here are a few additional tips to consider when installing electrical circuits in EMT:

Use The Correct Size Of EMT

It is important to use the correct size of EMT for your electrical installation. The NEC specifies the minimum size of EMT that must be used for different types and sizes of conductors. Using a larger size of EMT than required may result in wasted space and added cost, while using a smaller size may result in overcrowding and increased risk of overheating.

Ambient Temperature

The NEC specifies different allowable ampacities for conductors based on the ambient temperature. It is important to consider the ambient temperature when installing electrical circuits in EMT, as the temperature can affect the current-carrying capacity of the conductors.

Protect Against Corrosion

EMT is coated with a protective layer to prevent corrosion, but it is still important to take additional measures to protect against corrosion. This can include using corrosion-resistant conductors, applying a corrosion-resistant coating to the EMT, and using proper sealing and grounding techniques.

Use Proper Fittings

It is important to use proper fittings when installing electrical circuits in EMT to ensure a secure and reliable connection. The NEC specifies the types of fittings that can be used with EMT, and it is important to follow these guidelines to ensure the safety of the installation.

Follow Proper Installation Techniques

It is important to follow proper installation techniques when installing electrical circuits in EMT. This includes using the correct tools and equipment, following the manufacturer’s instructions, and observing proper safety precautions. It is also important to follow local building codes and obtain the necessary permits and inspections.

To Recap

The number of circuits that can be installed in 1/2 inch EMT depends on various factors, including the size and type of the conductors, the amount of current carried by the circuit, and the ambient temperature.

To ensure the safety and compliance of the electrical installation, it is important to follow the National Electric Code (NEC) and consult with a licensed electrician. The NEC provides guidelines, such as Table 310.16 and the rule of 40% fill, that can be used to determine the maximum number of circuits that can be installed in EMT.

By following these guidelines and taking proper safety precautions, you can ensure that your electrical installation is safe and meets the relevant codes and standards.