Foam Board Instead of Drywall: The Dangerous Mistake to Avoid

You’re staring at a stack of heavy drywall sheets, the inevitable cloud of dust, and the tedious process of mudding and sanding. There has to be a better way, you think. Then, you see it: lightweight, easy-to-cut foam board, promising insulation and a seemingly simpler path to a finished wall. But can this lightweight champion truly replace the heavyweight king of interior walls?

The idea of using foam board instead of drywall is tempting, offering a potential shortcut around the mess and muscle traditionally associated with finishing a room. However, this seemingly clever hack hides a significant danger that every homeowner and DIY enthusiast must understand. Before you make a potentially costly and hazardous mistake, let’s dive deep into the realities of this popular question.

You'll Learn About

What is Foam Board and Why Is It So Tempting?

Rigid foam board is a popular insulation material, prized for its high R-value (a measure of thermal resistance), moisture resistance, and ease of handling. It typically comes in three main types: Expanded Polystyrene (EPS), Extruded Polystyrene (XPS), and Polyisocyanurate (Polyiso). Each offers different levels of insulation and moisture protection, making them fantastic for insulating basements, exterior walls, and roofs.

Compared to drywall, foam board is incredibly lightweight, simple to cut, and doesn’t produce the fine, pervasive dust that gets into everything. This makes it an attractive option for workshops, garages, or basements where a pristine finish isn’t the top priority. The added insulation is a significant bonus, promising a more comfortable and energy-efficient space.

The Insulation and Moisture Advantage

Without a doubt, foam board is a superior insulator to drywall. A standard half-inch sheet of drywall has an R-value of less than 0.5, while foam boards can offer R-values of R-5 to R-8 or more per inch of thickness. This can make a substantial difference in spaces like garages or basements, helping to stabilize temperatures and reduce energy bills.

Furthermore, closed-cell foam boards like XPS and foil-faced Polyiso are excellent vapor barriers. They resist moisture absorption, which is a major advantage in below-grade applications like basements where dampness can be a constant concern. Drywall, on the other hand, can degrade and support mold growth when exposed to moisture.

The Critical Flaw: Fire Safety and Building Codes

Here is the single most important reason why you cannot simply swap drywall for foam board on your interior walls: fire safety. Standard foam board insulation is combustible. When exposed to flame, it can burn rapidly and release thick, toxic smoke, creating an incredibly dangerous situation in a fire.

Building codes are extremely clear on this point. The International Residential Code (IRC) and International Building Code (IBC) mandate that foam plastic insulation must be separated from the interior of a building by an approved 15-minute thermal barrier. The most common and accepted thermal barrier is 1/2-inch gypsum board—in other words, drywall.

Understanding Thermal Barriers

A thermal barrier is a material applied over foam insulation that is designed to slow the temperature rise of the foam during a fire. This delays the point at which the foam ignites, providing critical, life-saving time for occupants to escape. Drywall achieves this because its core is made of gypsum, a mineral that contains chemically bound water (calcium sulfate dihydrate).

When exposed to fire, this water is released as steam, a process called calcination. This process absorbs significant heat energy, keeping the opposite side of the drywall cooler for a period of time and protecting the flammable materials behind it. Foam board has no such inherent fire resistance.

Where Can You Use Foam Board on Walls? (With Caution)

Despite the fire code limitations, there are specific scenarios where foam board can be used on interior walls, but almost always as part of a larger wall system that includes a thermal barrier. It is rarely, if ever, acceptable as the final, exposed wall surface in a habitable space.

Basements and Garage Walls

In basements, it’s common practice to adhere rigid foam directly to the concrete foundation walls for insulation and moisture control. However, you must then build a stud wall in front of it and cover that wall with drywall. Leaving the foam exposed is a code violation and a serious fire hazard.

Similarly, in a garage or workshop, you might be tempted to just attach foam board for a quick, insulated finish. This is not permissible if the garage is attached to the house or considered an occupied space. You must cover it with drywall (often thicker, 5/8″ Type X fire-rated drywall is required on walls shared with the living space) or another approved thermal barrier.

A Note on “Fire-Rated” Foam Boards

Some manufacturers offer specialized products, like foil-faced polyisocyanurate boards (often called Thermax or CI Max), which have been tested and approved for exposed use in certain limited applications, like crawl spaces or attics. However, these products are not a universal solution and you must always verify their approval for your specific application with your local building code official before proceeding.

Comparing Foam Board and Drywall Head-to-Head

To make the choice clearer, let’s break down the key differences in a simple table.

| Feature | Foam Board (Rigid Polystyrene) | Standard 1/2″ Drywall |

|---|---|---|

| Primary Function | Insulation | Wall Finish / Thermal Barrier |

| R-Value (per inch) | ~R-5 (XPS) | ~R-0.9 (for a full inch) |

| Fire Resistance | Poor (Combustible) | Excellent (15-minute thermal barrier) |

| Moisture Resistance | Excellent (Closed-cell foam) | Poor (Standard) to Good (Moisture-resistant type) |

| Durability | Low (Easily dented and damaged) | Moderate (Can be damaged but easily repaired) |

| Ease of Installation | Very Easy (Lightweight, simple to cut) | Moderate (Heavy, dusty, requires finishing) |

| Cost (Material Only) | Higher than standard drywall | Lower than foam board |

How to Properly Install Foam Board as Part of a Wall System

If your goal is to add insulation, using foam board is a great idea—as long as you do it correctly. Here is the proper, code-compliant method for incorporating it into an interior wall.

Step 1: Attach Foam Board to the Wall

For concrete or block walls, use a compatible foam board adhesive to glue the sheets directly to the surface. For existing stud walls, you can place the foam board sheets over the studs. Ensure all seams are sealed with compatible construction tape to create a continuous air and vapor barrier.

Step 2: Frame a New Wall (If Necessary)

If you’ve attached the foam to a solid wall, you’ll need to frame a 2×4 stud wall directly in front of the foam. This creates the necessary structure to hang your drywall and provides a cavity for running electrical wiring and plumbing without compromising the insulation layer.

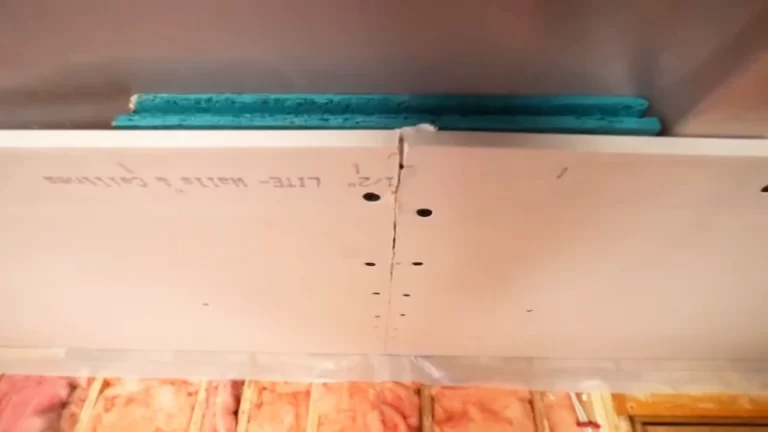

Step 3: Install the Thermal Barrier

This is the critical step. Hang 1/2-inch or 5/8-inch drywall over your studs, securing it with drywall screws. Knowing how to cut drywall on a stud properly will be essential here to ensure a clean installation around outlets and corners.

Step 4: Finish the Drywall

Proceed with taping, mudding, and sanding the drywall joints. The choice between different joint compounds, like exploring whether Easy Sand 45 vs 90 is better for your timeline, can make this process more efficient. Once finished and primed, your wall is safe, insulated, and ready for paint.

Frequently Asked Questions

Is it safe to use foam board instead of drywall?

No, it is generally not safe to use foam board as a direct replacement for drywall. Foam board is a combustible material and poses a significant fire hazard if left exposed. Building codes typically require a thermal barrier, such as 1/2-inch drywall, to be installed over foam insulation to slow the spread of fire.

Can foam board ever be used as a finished wall surface?

In most residential applications, foam board cannot be left as the final wall surface due to its flammability. Some specially rated commercial or industrial foam products may be left exposed in certain situations, but for home interiors, it must be covered by a fire-resistant material like drywall.

What are the building code requirements for installing foam board on interior walls?

Most building codes mandate that foam plastic insulation be separated from the building’s interior by an approved thermal barrier. The most common requirement is 1/2-inch gypsum board (drywall). This is to ensure fire safety and prevent the rapid spread of flames.

What is the primary advantage of using foam board on interior walls?

The main benefit of installing foam board on interior walls is for its insulation properties. It can significantly increase the R-value of a wall, leading to better energy efficiency and sound dampening. It is particularly effective against concrete walls, such as in a basement, before the final wall is framed.

How does the cost of foam board compare to drywall?

The cost can vary, but generally, foam board insulation is more expensive than drywall on a per-sheet basis. When used as intended for insulation, it is an additional cost to the drywall itself. Using it as a drywall replacement would not be a cost-saving measure, especially considering the necessary fire-resistant covering.

The Final Verdict: A Tool, Not a Replacement

So, can you use foam board instead of drywall? The answer is a definitive no. Foam board should be seen as a high-performance insulation material that works *with* drywall, not as a substitute for it. Its lack of fire resistance makes it an unsafe and non-compliant choice for an exposed interior wall finish.

While the dream of a dust-free, lightweight wall solution is appealing, safety must always come first. Embrace foam board for its incredible insulating and moisture-handling properties, but always give it the proper respect—and the proper covering—that building codes and common sense demand. By pairing it correctly with drywall, you can create a wall that is not only easy to finish but also safe, durable, and exceptionally energy-efficient.