Relocating Your Air Handler: Is the High Cost Worth It?

Is that bulky air handler taking up valuable closet space? Are you finishing your basement and need it moved? Many homeowners face the dilemma of needing to relocate their air handler but are often shocked by the complexity and cost involved. It’s a project that seems simple on the surface but quickly reveals a web of interconnected systems—ductwork, electrical lines, and refrigerant pipes—that all demand professional attention.

Relocating an air handler isn’t just about moving a box from point A to point B. It’s a significant HVAC project that can improve your home’s layout and functionality, but only when done correctly. This guide will break down the true cost of relocating your air handler, explore the factors that drive the price up, and help you decide if it’s a worthwhile investment for your home.

You'll Learn About

Why Relocate an Air Handler in the First Place?

Before diving into the costs, it’s essential to understand the common reasons homeowners decide to take on this project. The motivation is rarely arbitrary; it’s typically driven by a tangible need to improve the home’s living space or system performance.

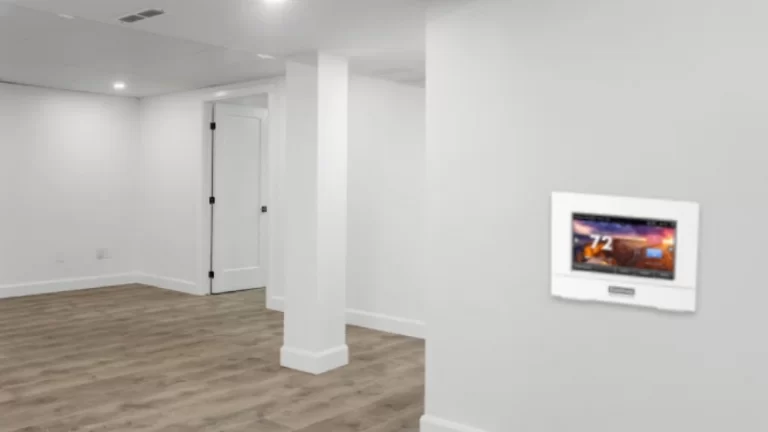

Common motivations include home renovations, such as finishing a basement or reclaiming a utility closet for more functional storage. Noise reduction is another significant factor; moving a loud unit from a central living area to a garage or attic can dramatically improve home comfort. Sometimes, the move is about enhancing efficiency, for example, by relocating the unit from a scorching hot attic to a more temperate basement, reducing the strain on the system.

Key Reasons for Relocation:

- Space Optimization: Freeing up a closet or utility room for other uses is one of the most popular reasons. This is especially common during major home remodeling projects.

- Noise Reduction: Air handlers, especially older models, can be noisy. Moving them to a more remote location like an attic or garage minimizes disruptions in living areas.

- Accessibility and Maintenance: If your unit is in a hard-to-reach crawl space or a cramped closet, moving it can make routine maintenance and future repairs much easier and less costly.

- Improved Efficiency: An air handler located in an unconditioned space, like a hot attic, has to work much harder. Relocating it to a conditioned or semi-conditioned space like a basement can lead to better performance and lower energy bills.

Breaking Down the Cost to Relocate an Air Handler

Moving an air handler is a labor-intensive process that involves multiple trades. The cost to move an air handler typically ranges from $1,500 to $3,000 or more. This price can fluctuate significantly based on several key variables. Unlike a simple appliance replacement, this job is a custom project tailored to your home’s specific layout and HVAC system.

The final invoice will cover much more than just the physical moving of the unit. It includes the cost of new materials, skilled labor from certified technicians, and potentially permits and inspections. Understanding these components is crucial for accurately budgeting for your project and avoiding unexpected expenses.

Primary Factors Influencing the Relocation Cost

No two air handler relocation jobs are the same. The distance of the move, the complexity of your home’s construction, and the type of system you have all play a pivotal role in the final price tag. Here’s a closer look at what drives the cost.

1. Distance and Location

The most significant cost factor is how far the unit is being moved and its new location. A short move of just a few feet within the same room will be on the lower end of the cost spectrum. Moving the unit to a different floor, such as from a first-floor closet to the attic or basement, is a much more complex and expensive job.

Moving to a new floor involves extensive modifications to ductwork, electrical wiring, refrigerant lines, and the condensate drain line. For instance, relocating a unit to an attic may require reinforcing the structure to support the unit’s weight and installing a secondary drain pan to prevent water damage. This requires significantly more labor and materials.

2. Ductwork Modifications

Your existing ductwork is designed to connect to the air handler in its current location. When the unit moves, the entire duct system must be reconfigured. This can range from simple extensions to a complete redesign of the supply and return plenums. The cost of ductwork modifications can add hundreds or even thousands of dollars to the project.

If the new location changes the dynamics of airflow, your technician may need to perform calculations to ensure the system remains balanced. Improperly sized or installed ductwork can lead to poor performance, creating hot and cold spots throughout your home and negating any potential efficiency gains. In some cases, you might decide to use this opportunity to upgrade your ductwork, especially if you’re experiencing issues like poor insulation. If you’re dealing with old insulation, it’s a good time to consider removal, a process that can be managed with tools like a shop vac for blown insulation, before new ducts are installed.

3. Refrigerant and Electrical Lines

The air handler is connected to the outdoor condenser unit via a set of copper refrigerant lines (the line set). Moving the air handler requires a licensed HVAC technician to safely pump down and recover the refrigerant, disconnect the lines, and then reinstall them. In most cases, the existing line set cannot be reused and a new, longer one must be installed, which adds to the material cost.

Similarly, the electrical wiring that powers the unit and connects it to the thermostat will need to be moved and extended. This work must be done by a qualified individual to ensure it complies with local electrical codes, which adds to the labor cost. Poor electrical work is a serious fire hazard.

4. Condensate Drain Line

During the cooling process, your air handler produces condensation that must be safely drained away. Moving the unit requires re-routing the condensate drain line. This can be complex, as the line must have a continuous downward slope to drain properly via gravity. If a gravity drain isn’t feasible in the new location, a condensate pump will need to be installed, adding another $150 to $250 to the total cost.

Cost Breakdown Table

To give you a clearer picture, here is a table estimating the potential costs associated with relocating an air handler. Prices are approximate and can vary based on your location and the specifics of the job.

| Cost Component | Estimated Price Range | Notes |

|---|---|---|

| HVAC Labor | $800 – $1,500+ | Typically billed at $75-$150 per hour. Complex moves can take 1-2 full days. |

| New Refrigerant Line Set | $200 – $500 | Cost depends on the length and diameter required. |

| Ductwork Modifications | $300 – $2,000+ | Varies widely based on the extent of changes needed. |

| Electrical Work | $200 – $600 | Includes extending wiring and ensuring code compliance. |

| Condensate Pump (if needed) | $150 – $250 | Required if a gravity drain is not possible. |

| Permits and Inspections | $100 – $500 | Required in most municipalities for this type of work. |

| Drywall Repair & Painting | $200 – $700 | Often necessary after running new lines and ducts through walls and ceilings. |

The Relocation Process: What to Expect

Understanding the steps involved can help you prepare for the project and ensure it goes smoothly. A professional relocation is a multi-stage process that requires careful planning and execution.

From the initial consultation to the final system test, each step is critical. A reputable HVAC contractor will follow a methodical approach to minimize disruption to your home and ensure the system operates correctly in its new location. This is not a DIY project due to the need for specialized tools and certifications, especially for handling refrigerant.

Step-by-Step Relocation Guide:

- Professional Assessment: A technician will visit your home to evaluate the current setup, discuss the desired new location, and identify any potential challenges. They will measure for new duct runs, line sets, and electrical wiring to provide an accurate quote.

- System Preparation: On the day of the job, the technician will shut off power to the unit and safely recover the refrigerant from the system. This is a critical step that requires EPA certification.

- Disconnection: The technician will then disconnect the electrical wiring, drain line, refrigerant lines, and ductwork from the air handler.

- Moving the Unit: The air handler is physically moved to its new location. If it’s going into an attic or other elevated space, a support platform and secondary drain pan will be installed.

- Reconnection: New ductwork, refrigerant lines, electrical wiring, and a condensate drain are run to the new location and connected to the unit. This is often the most time-consuming part of the job.

- System Charging and Testing: Once everything is reconnected, the system is pressure tested for leaks, evacuated to remove moisture, and recharged with the precise amount of refrigerant. The technician will then turn the system on and perform a series of tests to ensure it is operating safely and efficiently.

Hidden Costs and Unforeseen Complications

While a detailed quote from a contractor should cover the primary expenses, there are often hidden costs and potential complications that can arise during a project of this nature. Being aware of these possibilities can help you budget for contingencies.

For instance, opening up walls and ceilings can reveal pre-existing issues like pests, mold, or structural problems that need to be addressed before the HVAC work can continue. Older homes may have outdated wiring or asbestos-containing materials that require remediation, adding unexpected costs to the project.

Potential Additional Expenses:

- Structural Modifications: If you’re moving the unit to an attic, you may need to hire a contractor to reinforce the joists to handle the weight. Discussing structural integrity, especially if dealing with issues like a bowed post, might be necessary. There are solutions for how to straighten a bowed 4×4 post that could be relevant in larger renovation contexts.

- Code Upgrades: The new location may trigger requirements for other systems to be brought up to current building codes, such as electrical or ventilation standards.

- Cosmetic Repairs: The cost of patching and painting drywall, or replacing flooring where the old unit was located, is not always included in the HVAC contractor’s quote.

- System Performance Issues: If the relocation is not planned carefully, it can negatively impact your system’s static pressure, leading to reduced airflow and efficiency. A good contractor will perform calculations to prevent this, but it’s a critical point of discussion.

Is It Better to Relocate or Replace Your Air Handler?

Given the significant cost and complexity of relocating an air handler, it’s wise to consider the age and condition of your current unit. If your system is more than 10-15 years old, it may be more cost-effective in the long run to invest in a complete replacement rather than paying to move an aging unit.

A new air handler will offer higher efficiency, better performance, and a new warranty. While the upfront cost of replacement is higher than relocation alone, the long-term energy savings and avoidance of future repair costs on an old unit can make it a smarter financial decision. When finishing a basement, choosing the right wall system, like a Dricore Smartwall alternative, can also contribute to overall home efficiency alongside a new HVAC system.

When to Relocate:

- Your current air handler is relatively new (under 10 years old) and in excellent condition.

- The relocation is a necessity for a major home renovation project.

- The move is short and straightforward, keeping costs on the lower end.

When to Replace:

- Your system is over 12 years old or uses the outdated R-22 refrigerant.

- The unit has required multiple repairs in recent years.

- The cost of relocation is more than 50% of the cost of a new, more efficient system.

Final Thoughts: Making the Right Decision

The decision to relocate your air handler is a significant one that involves a careful balance of cost, necessity, and long-term value. While the price tag of $1,500 to $3,000 might seem steep, the benefits of reclaiming valuable living space or reducing noise can make it a worthwhile investment for many homeowners.

The key to a successful project is hiring a qualified and experienced HVAC professional. Always get multiple quotes, ask detailed questions about the process and what’s included, and ensure the contractor is licensed and insured. By doing your homework, you can ensure your air handler relocation is done safely, correctly, and provides lasting value to your home.