Skim Coat Popcorn Ceiling: The Ultimate Guide to a Flaw-Free Finish

That popcorn ceiling has been staring down at you for years. It’s the last relic of a bygone design era, trapping dust, casting strange shadows, and making your room feel dated and dark. You know it has to go, but the thought of the monumental mess and potential hazards of scraping it all down is enough to make anyone procrastinate.

The good news is there’s a better way. Skim coating is a transformative technique that covers the ugly texture, creating a modern, smooth, and clean surface without the extreme disruption of a full removal. This process involves applying thin layers of joint compound directly over the popcorn texture, effectively burying it for good.

You'll Learn About

Why That Textured Ceiling Has to Go: The Problem with Popcorn

Popcorn ceilings, also known as acoustic or stucco ceilings, were popular from the 1950s through the 1980s. They were a quick and easy way for builders to hide imperfections in the ceiling drywall. However, their time has long passed, and now they present several problems for homeowners.

Beyond their dated appearance, these textures are notoriously difficult to clean and even harder to repair. They act like magnets for dust, cobwebs, and allergens. For many, the desire for a smooth ceiling is about creating a brighter, more modern, and healthier living space.

Skim Coating: The Smarter, Cleaner Alternative to Removal

Instead of embarking on a messy and potentially hazardous scraping project, skim coating offers a much more elegant solution. It’s a method that allows you to achieve a perfectly smooth ceiling by applying a new surface directly over the old one. The benefits are significant: it dramatically reduces the amount of dust and debris, it can be more cost-effective, and it safely encapsulates the old texture.

This is especially important if your home was built before the mid-1980s, as many older popcorn ceilings contain asbestos. Skim coating allows you to cover it without disturbing the dangerous fibers, a process known as encapsulation. This makes it a safer choice for you and your family.

The Critical First Step: Asbestos Testing

Before you touch your ceiling, you must address the risk of asbestos. Homes built before 1982 have a high probability of containing asbestos in their popcorn texture. Disturbing this material by scraping or even aggressive sanding can release harmful fibers into the air, which are linked to serious health conditions.

Testing is simple and non-negotiable. You can purchase an at-home test kit or hire a professional to take a sample. If the test comes back positive, skim coating is one of the safest ways to deal with it, as it avoids disturbing the asbestos. Full removal should only be handled by a licensed abatement professional.

Before You Begin: A Game-Changing Reality Check

Skim coating a ceiling is a project that requires patience and physical effort, but it is well within the reach of a determined DIYer. It is not a quick fix; it’s a multi-step process that involves careful preparation, application, and finishing work. Be prepared to work overhead for extended periods, which can be strenuous on your neck, shoulders, and back.

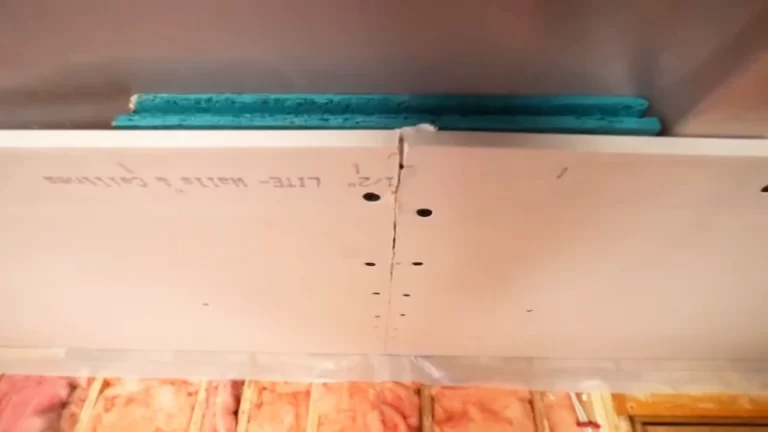

A crucial factor that is often overlooked is the added weight. Joint compound is heavy, and applying multiple layers will add a significant load to your ceiling drywall. Before you start, inspect your ceiling for any signs of sagging, water damage, or structural weakness. Ensuring the ceiling is secure is a vital safety precaution.

Assembling Your Arsenal: Tools and Materials for a Perfect Finish

Having the right tools is essential for achieving a professional-looking finish. Rushing this step or trying to make do with improper equipment will lead to frustration and a subpar result. Below is a comprehensive list of what you’ll need.

| Item | Purpose | Pro-Tip |

|---|---|---|

| Asbestos Test Kit | Safety Check | Do not skip this step for homes built before the mid-1980s. |

| Plastic Sheeting & Rosin Paper | Room Protection | Double-cover floors. Use tape to secure plastic to the top of your walls. |

| Stain-Blocking Primer (Oil or Shellac-based) | Sealing the Ceiling | Prevents the water in the mud from soaking into the popcorn texture, which can cause it to fall off. |

| All-Purpose Joint Compound | The Skim Coat Material | Choose a standard all-purpose compound for the best adhesion and strength. |

| 5-Gallon Bucket | Mixing Compound | You will need a clean bucket dedicated to your mud mixture. |

| Paddle Mixer Drill Attachment | Ensuring Consistency | Mixing by hand is difficult and often leaves lumps. A paddle mixer is a must-have. |

| 12″ or 14″ Taping Knife | Applying the Compound | A wider knife helps to spread the mud more evenly and requires fewer passes. |

| Mud Pan | Holding Compound | A mud pan is much easier to work with on a ladder or scaffold than a heavy bucket. |

| Sturdy Ladder or Scaffolding | Access & Safety | Ensure your work platform is stable and allows you to reach the ceiling comfortably. |

| Pole Sander & Sanding Screens | Smoothing the Surface | Use a medium grit (120-150) for sanding between coats and a fine grit (180-220) for the final finish. |

| Shop Vacuum with Dust Filter | Cleanup | Essential for controlling dust during the sanding phase. |

| Safety Gear (Goggles, Mask/Respirator) | Personal Protection | Protect your eyes and lungs from dust and potential contaminants. |

The 7-Step Method to Skim Coat Your Popcorn Ceiling

Follow these steps methodically for a smooth, professional-grade finish. Remember, patience is your greatest tool throughout this process. Rushing will only create more work for you later.

Step 1: Meticulous Preparation and Room Protection

This is the most important step for a stress-free project. Remove all furniture from the room if possible. What you can’t remove, group in the center of the room and cover completely with heavy plastic sheeting. Cover the entire floor with rosin paper, followed by another layer of plastic sheeting. Use painter’s tape to seal the edges where the floor meets the walls.

Turn off the power to the room at the breaker box and remove any ceiling fans or light fixtures. Cover the electrical boxes with painter’s tape. Finally, tape plastic sheeting along the top edge of the walls to protect them from mud splatters.

Step 2: Address Ceiling Imperfections First

Before you can add a new surface, you must ensure the existing one is stable. Use a wide putty knife to gently knock down any obvious high points or loose chunks of the popcorn texture. Be careful not to gouge the drywall underneath.

Look for any cracks, water stains, or damaged areas. These must be repaired and allowed to dry completely before you proceed. Water stains should be sealed with a stain-blocking primer to prevent them from bleeding through your new finish.

Step 3: The Make-or-Break Priming Stage

Do not apply joint compound directly to an unprimed popcorn ceiling. The moisture from the mud will absorb into the texture, re-wetting it and causing it to fall off in sheets, creating a disastrous mess. You must seal the entire ceiling with a high-quality, stain-blocking primer. Oil-based or shellac-based primers are excellent choices as they create an impermeable barrier.

Apply the primer evenly with a roller and allow it to dry completely according to the manufacturer’s instructions. A good primer coat is the foundation for a successful skim coat, so ensuring you know how much PVA primer you might need is a crucial part of the planning. Depending on the ceiling’s condition, understanding how many coats of primer are necessary will ensure a solid base.

Step 4: Mixing Your Joint Compound to Perfection

Your goal is to achieve a smooth, creamy consistency, similar to thick pancake batter or creamy peanut butter. Start by putting some all-purpose joint compound into your 5-gallon bucket and add a small amount of water. Use your paddle mixer on a low speed to blend it thoroughly, scraping the sides of the bucket as you go.

Add water gradually until you reach the desired consistency. A mix that is too thick will be difficult to spread, while a mix that is too thin won’t provide adequate coverage and will be prone to dripping. Getting the mix right is key to a smooth application.

Step 5: Applying the First Skim Coat

Now the transformation begins. Scoop some of your mixed compound into your mud pan. Using your 12-inch or 14-inch taping knife, apply a thin, even layer of mud to a small section of the ceiling (e.g., a 4×4 foot area). Hold the knife at a low angle (around 15 degrees) to apply the mud, then increase the angle (around 30-45 degrees) to smooth it out.

The goal of the first coat is not to completely cover the popcorn texture. Its purpose is to fill in the deep valleys between the “popcorns.” Don’t worry about making it perfect; focus on applying a consistent, thin layer. Overworking the mud will cause it to dry out and become unmanageable.

Step 6: The Second (and Maybe Third) Coat

Allow the first coat to dry completely, which usually takes about 24 hours. Once dry, use your taping knife to gently scrape off any ridges or high spots. Do not sand at this stage. Wipe the ceiling with a damp cloth to remove any dust.

Apply the second coat in the same manner as the first, but work in a direction perpendicular to your first coat. This cross-hatching technique helps to build a flatter, more even surface. The second coat should fill in most of the remaining texture. For an exceptionally smooth result, a third, very thin coat may be necessary after the second has dried and been scraped.

Step 7: The Final Sand, Prime, and Paint

After your final coat is completely dry, it’s time for the finishing touches. Using a pole sander with a fine-grit sanding screen (180-220 grit), lightly sand the entire ceiling. Your goal is to smooth out minor imperfections, not to remove a significant amount of the compound. Use a light touch and keep the sander moving to avoid creating grooves.

After sanding, the ceiling will be covered in fine dust. Wipe the entire surface down with a damp cloth or a tack cloth. Once clean and dry, apply a coat of high-quality drywall primer to seal the new surface. Finally, you are ready to paint your new, beautifully smooth ceiling.

Common Skim Coating Disasters and How to Avoid Them

Even with careful planning, issues can arise. Knowing how to troubleshoot them is key. The most common problem is bubbles appearing in the mud as it dries. This is almost always caused by inadequate priming, where moisture is escaping from the underlying texture and pushing through the new mud.

Visible trowel marks and ridges are another frequent issue. This usually results from applying the mud too thickly, overworking it, or holding the taping knife at too steep an angle. Remember, multiple thin coats are always superior to one thick coat. If you find significant imperfections after a coat dries, it’s better to scrape them down rather than trying to sand them away.

The Unspoken Consequence: Losing Acoustic Dampening

One aspect that is rarely discussed is the change in room acoustics. Popcorn ceilings are also called “acoustic ceilings” for a reason. Their rough, porous surface is effective at absorbing sound waves and reducing echo within a room. When you create a flat, hard surface, sound will reflect much more.

After skim coating, you may notice that your room sounds more “live” or echoey. This is a normal consequence of changing the surface texture. If sound control is a concern, you can mitigate this effect by incorporating soft materials into your room’s decor, such as area rugs, heavy curtains, upholstered furniture, and fabric wall art.

Frequently Asked Questions (FAQ)

Can you skim coat a painted popcorn ceiling?

Yes, and in many cases, it’s preferable. A layer of paint often means the texture is more stable and less likely to absorb moisture, but you must still clean and prime the surface thoroughly before skim coating.

How much does it cost to skim coat a popcorn ceiling?

The cost can vary significantly based on your location and whether you do it yourself or hire a professional. DIY costs are primarily materials, which can range from $100 to $300 for an average-sized room. Professional work can cost between $1.50 to $3.00 per square foot, or more, depending on ceiling height and complexity.

What is the best joint compound for this job?

An all-purpose, ready-mixed joint compound is the best choice for this project. It has good adhesive properties and a strong finish. Avoid using “topping” compound for the initial coats, as it has less glue and may not adhere as well to the primed popcorn surface.

Is Skim Coating a Popcorn Ceiling Worth It?

Absolutely. While it requires a commitment of time and effort, skim coating a popcorn ceiling is one of the most impactful DIY projects you can undertake. It fundamentally transforms the character of a room, making it feel brighter, cleaner, and more modern.

By choosing to skim coat, you avoid the incredible mess of removal and safely contain potentially hazardous materials. The result is a flawless, smooth ceiling that will dramatically increase your home’s appeal and your enjoyment of the space for years to come.