Can You Lower a fireplace box? Your Guide to a Better View

You have the perfect spot for your TV above the fireplace, but there’s a problem. The fireplace box is just too high, forcing you to crane your neck to watch your favorite shows. This is a common design frustration in many homes.

A high fireplace can disrupt the room’s aesthetic and create an uncomfortable viewing experience. Fortunately, you’re not stuck with this awkward setup. It is often possible to lower a fireplace box, but it’s a project that requires careful planning and consideration.

You'll Learn About

Why Your Fireplace Box is Too High

Understanding why your fireplace was installed at an awkward height is the first step. Often, the placement is a matter of construction convenience or outdated design trends rather than optimal room layout. Builders may have positioned it to simplify venting or to match a pre-existing mantel style.

Another reason could be the type of fireplace unit. Some zero-clearance prefabricated models have specific height requirements for safety and proper function. These manufacturer specifications dictate the minimum distance required from the floor and surrounding combustible materials.

The Problem with a High Fireplace Opening

The most immediate issue with a high firebox is the ergonomic nightmare it creates for mounting a television. Staring up at a screen for extended periods can lead to neck strain and discomfort. Aesthetically, it can make the entire wall feel unbalanced and top-heavy.

Beyond television placement, a high fireplace can also be a safety concern. It might be harder to manage the fire, add logs, or clean the interior. The heat distribution can also be less effective, with warmth rising towards the ceiling instead of radiating out into your living space.

Solutions: How to Lower a Fireplace Box

Lowering a fireplace box is a significant renovation project, not a simple weekend task. It involves structural alterations to the wall and potentially the chimney or venting system. Safety and code compliance are paramount.

The complexity of the job depends heavily on the type of fireplace you have: a traditional masonry fireplace or a prefabricated (zero-clearance) unit. Each requires a different approach.

Lowering a Prefabricated Fireplace Unit

Prefabricated fireplaces are factory-built metal boxes that are installed within a wooden frame. These are generally easier and less expensive to reposition than their masonry counterparts. However, the process is still complex.

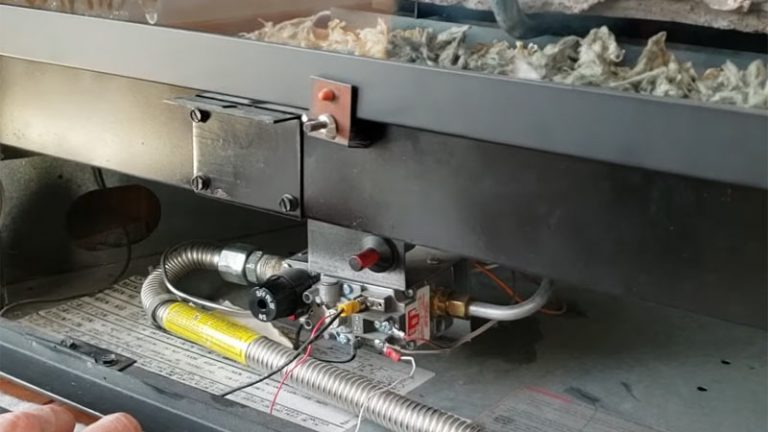

The project involves carefully deconstructing the wall around the fireplace. This includes removing the drywall, mantel, and any surrounding tile or stone. You must disconnect the gas line and electrical wiring before moving the unit.

Once the unit is exposed, the support framing must be rebuilt at a lower height. It’s crucial that this new framing is structurally sound and meets all local building codes and the manufacturer’s installation requirements for clearances. If you notice a draft, it might be related to other issues like a cold air leak in your gas fireplace.

Tackling a Masonry Fireplace

Lowering a traditional masonry fireplace is a much more intensive and costly undertaking. These fireplaces are built from brick or stone and are an integral part of your home’s structure. This is not a DIY project and requires a professional mason.

The process involves demolishing the existing firebox and hearth and rebuilding it at the desired height. This includes intricate brick or stone work and ensuring the smoke chamber and flue are correctly realigned. Altering a masonry structure can affect its structural integrity and safety.

Key Steps in the Lowering Process

Regardless of the fireplace type, the general process follows a clear sequence. Proper planning and execution are essential to ensure a safe and successful outcome. Rushing the job can lead to costly mistakes and safety hazards.

If you encounter unusual smells during or after the project, such as a burning plastic odor, it could indicate an issue with new components or wiring. You can learn more about why your electric fireplace smells like burning plastic to troubleshoot potential causes.

Step 1: Assessment and Planning

The first step is always a thorough assessment. You need to identify the type of fireplace, check manufacturer specifications for clearance requirements, and inspect the chimney and venting system. A professional consultation is highly recommended at this stage.

This is also the time to plan your new design. Determine the ideal height for your firebox, considering both your TV placement and the overall look of the room. You’ll also need to choose new finishing materials like tile, stone, or a mantel.

Step 2: Demolition and Preparation

This is the messy part. The area must be cleared, and protective coverings laid down to control dust and debris. The wall around the fireplace is carefully opened up to expose the firebox and its framing or masonry.

For gas or electric units, all utility lines must be safely disconnected by a qualified professional. Never attempt to handle gas lines yourself.

Step 3: Rebuilding and Installation

With the old structure removed, the new, lower support system is built. For prefab units, this means new wood framing. For masonry fireplaces, it means laying new bricks or stone for the firebox and hearth.

The fireplace unit is then set into its new position, and all vents, gas lines, and electrical connections are re-established. Proper sealing and insulation are critical to prevent drafts and ensure efficiency. An improperly functioning unit can sometimes lead to issues like a pellet stove overheating, so professional installation is key.

Step 4: Finishing and Restoration

Once the firebox is securely in place and has passed inspection, the wall can be closed up. This involves installing new drywall, followed by your chosen surround material, such as tile, stone veneer, or marble. The final step is installing the new mantel and painting the surrounding walls.

Hiring a Professional vs. DIY

While some experienced DIYers might be tempted to tackle the framing and drywall, lowering a fireplace box is a project best left to professionals. There are numerous safety codes and structural considerations that require expert knowledge.

A certified fireplace technician or a general contractor with specific experience in fireplace installations should handle the job. They will ensure the project is done safely, meets all local building codes, and functions correctly. The risks associated with improper installation, including fire hazards and carbon monoxide leaks, are too great.

| Aspect | DIY Approach | Professional Hire |

|---|---|---|

| Cost | Lower material and labor costs initially. | Higher upfront cost due to labor. |

| Safety | High risk of errors related to gas lines, venting, and structural support. | Ensures all work is up to code and safely executed. |

| Timeline | Can be significantly longer and prone to delays. | Defined project timeline with experienced crew. |

| Expertise | Requires advanced knowledge of carpentry, electrical, and potentially masonry. | Access to certified professionals and specialized knowledge. |

| Permits | Homeowner is responsible for obtaining necessary permits and inspections. | Contractor typically handles all permits and inspections. |

How Low Can a Hearth Be?

When designing a fireplace, one important decision to make is whether to install a raised hearth or a floor-level hearth. Each option has its distinct advantages and considerations, especially when it comes to height and the amount of space it occupies. But just how low can a hearth be? Let’s explore the differences between raised and floor-level hearths, and how low a hearth can be built, while still ensuring safety, functionality, and aesthetics.

Raised Hearths

A raised hearth typically sits 12 to 18 inches above the floor. This elevated position serves several purposes: it adds a visual layer of dimension to the room, draws attention to the fireplace, and provides a convenient place to sit or rest objects like firewood or decorations. The raised hearth extends about 16 to 18 inches from the fireplace opening, creating a functional ledge.

While raised hearths have a more traditional and formal appearance, they also provide a level of protection from heat. With a raised hearth, the distance between the flames in the firebox and the floor reduces the likelihood of heat radiating directly onto carpets or flooring. In some cases, raised hearths are designed to make the fireplace feel like a focal point of the room, elevating it both literally and figuratively.

However, raising the hearth too much can sometimes feel cumbersome or unnecessary, especially in modern or minimalist designs. In those cases, opting for a hearth that sits slightly lower might be preferred.

Floor-Level Hearths

In contrast, floor-level hearths sit flush with the floor, creating a clean, streamlined look. These types of hearths are less intrusive in terms of space and often make smaller rooms feel less crowded or heavy. A floor-level hearth is ideal for more contemporary or casual spaces where minimalism is a key design feature.

With a floor-level hearth, the flames of the firebox are closer to the room’s floor, which can give the fireplace a more intimate and cozy feel. It can also make the fire more accessible, especially when used for ambiance or warmth. However, one potential downside is that floor-level hearths require materials that can withstand heat exposure, especially on floors like wood or carpet.

A floor-level hearth also takes up less physical and visual space, making it ideal for people who want the warmth of a fireplace without it becoming a large design element. It sits at the same level as the floor, typically extending only a few inches beyond the opening of the fireplace.

How Low Can a Hearth Be?

The minimum height for a hearth generally depends on both building codes and safety standards. In most residential settings, fire safety codes require that the hearth be raised enough to prevent the spread of heat to surrounding areas. While floor-level hearths can be visually appealing and functional, they still need to meet safety guidelines, particularly regarding the materials used and heat distribution.

For a floor-level hearth to comply with safety standards, the hearth should be constructed with non-combustible materials (like brick, stone, or concrete) to protect surrounding floors from heat. Floor-level hearths may need to extend at least 16 inches in front of the fireplace opening, depending on the type of firebox and local building codes.

Final Thoughts on Your Fireplace Project

Lowering a fireplace box is a transformative project that can dramatically improve the comfort and aesthetics of your living space. It solves the common problem of an awkwardly high TV and creates a more balanced, modern focal point for the room.

While it is a complex and often costly endeavor, the end result is a more functional and enjoyable home. Always prioritize safety and professional expertise to ensure your new fireplace is not only beautiful but also operates safely for years to come.