Pellet Stove Overheating? Stop Ignoring These Critical Signs

There’s nothing quite like the consistent, radiant warmth of a pellet stove on a cold day. It’s an efficient and cost-effective heating solution for many homes. But that comfort can quickly turn to concern when the dreaded overheating error appears, or you notice your stove shutting down unexpectedly. A pellet stove overheating is more than just an inconvenience; it’s a critical safety warning that demands immediate attention.

Ignoring the signs of an overheating stove can lead to component damage, costly repairs, and in the worst-case scenario, a serious fire hazard. Understanding why your stove is overheating is the first step toward a safe and effective solution. This comprehensive guide will walk you through the common causes, provide step-by-step troubleshooting, and offer preventive maintenance tips to ensure your pellet stove runs safely and efficiently for years to come.

You'll Learn About

Why Is My Pellet Stove Overheating? Uncovering the Root Causes

A pellet stove is a complex appliance with several interconnected systems working to produce heat safely. When one of these systems fails or is impeded, the result is often excess heat that cannot be properly dissipated. This triggers the stove’s high-limit safety sensors, forcing a shutdown. Let’s break down the most common culprits behind this frustrating problem.

Blocked Airflow: The Most Common Culprit

Your pellet stove needs to breathe. It relies on a constant, unrestricted flow of air to function correctly. Air is needed for combustion in the burn pot and for transferring heat out into your room. When this airflow is blocked, heat builds up inside the stove’s body with nowhere to go, leading directly to an overheating situation.

Key areas to check for airflow restrictions include the room air intake, the exhaust vent (flue), and the internal air passages. Even a partially blocked vent can significantly reduce the stove’s ability to cool itself. The convection fan, responsible for blowing warm air into your home, can also become clogged with dust and debris, preventing it from doing its job effectively.

Faulty Components: When a Part Fails

Sometimes, the problem isn’t a blockage but a mechanical or electrical failure. Your stove is equipped with several sensors designed to monitor temperatures. The most important of these is the high-limit switch (or high-temperature sensor). This is a safety device that automatically shuts the stove down if internal temperatures exceed a preset limit.

If this switch becomes faulty, it can trigger a shutdown even when the stove isn’t actually overheating, or worse, fail to trigger when it is. Similarly, a malfunctioning convection blower will fail to circulate air, causing heat to build up rapidly. A faulty control board, the “brain” of the stove, can also send incorrect signals to the fans and auger motor, disrupting the delicate balance of fuel and air.

Poor Fuel Quality or Feed Rate Issues

The pellets you burn have a significant impact on your stove’s performance. Low-quality pellets with high moisture or ash content can create “clinkers”—hard, glassy deposits in the burn pot. These clinkers obstruct airflow through the burn pot, leading to inefficient combustion and a buildup of heat.

An incorrect auger feed rate can also be the cause. If the auger is feeding pellets into the burn pot faster than they can be efficiently burned, the fire will grow too large and hot. This overwhelms the stove’s capacity to exhaust the heat, inevitably causing an overheat shutdown. It’s crucial to match the feed rate to the quality of your pellets and your desired heat output.

Improper Installation and Ventilation

A pellet stove’s performance is highly dependent on its initial installation. If the stove does not have adequate clearance from combustible materials as specified by the manufacturer, heat can become trapped around the unit. More commonly, issues arise from an improperly installed ventilation pipe.

A vent pipe with too many bends, an excessive horizontal run, or an incorrect diameter will restrict the flow of exhaust gases. This “backpressure” forces heat to remain within the stove, quickly leading to an overheating error. Proper ventilation is paramount for both performance and safety.

Your Step-by-Step Guide to Fixing an Overheating Pellet Stove

Now that you understand the potential causes, it’s time to take action. Follow these systematic steps to diagnose and resolve the overheating issue. Always unplug your stove from the electrical outlet and ensure it is completely cool before performing any maintenance or inspection.

Step 1: Immediate Safety Checks and Shutdown

If your stove is currently in an overheat state, the first priority is safety. Most modern stoves will shut down automatically. If yours hasn’t, turn it off immediately. Do not attempt to restart it until you have identified and fixed the underlying problem. A visual inspection for any signs of soot or smoke leakage around seals and vents is a crucial first step.

Step 2: The Deep Clean Your Stove Desperately Needs

The vast majority of overheating issues are resolved with a thorough cleaning. Neglected maintenance is the primary enemy of a well-functioning pellet stove. You will need a good ash vacuum (not a regular household vacuum), brushes, and protective gear.

Clean the Burn Pot: Remove the burn pot and scrape away any clinkers or carbon buildup. Ensure all the small air holes in the pot are clear, as these are vital for proper combustion.

Empty the Ash Pan: Ash buildup in the pan and internal chambers can severely restrict airflow. Vacuum all accessible areas inside the firebox.

Clean the Heat Exchangers: Many stoves have tubes or channels that transfer heat to the convection air. Use a long-handled brush to clean soot and fly ash from these passages.

Inspect and Clean the Fans: Check the convection fan (room blower) and the combustion fan (exhaust blower). Carefully clean the fan blades to remove any accumulated dust and debris that could be slowing them down.

Clear All Vents: Disconnect the exhaust pipe and clean it thoroughly with a flue brush. Ensure there are no blockages from ash, soot, or even bird nests. Check the fresh air intake vent as well to make sure it’s unobstructed.

Step 3: Inspecting Key Safety Sensors

With the stove clean, you can check the key components. The high-limit switch is often a small, disc-shaped sensor mounted on the back of the stove or near the hopper. Check for loose connections. While testing the switch itself often requires a multimeter and some technical knowledge, ensuring it’s clean and its wiring is secure is a good homeowner check.

Step 4: Calibrating Your Feed Rate and Blower Speed

Consult your owner’s manual to understand how to adjust the settings on your stove. If you have been experiencing very large, roaring fires, your feed rate is likely too high.

Try reducing the feed rate setting. Conversely, ensure your blower speed is set appropriately to move air through the system. Some stoves link these settings, while others allow independent adjustment.

| Symptom | Potential Cause | Solution |

|---|---|---|

| Stove shuts down with a high-temp error code. | Blocked Airflow | Perform a thorough cleaning of the burn pot, ash traps, heat exchangers, and all vents (intake and exhaust). |

| Convection fan isn’t blowing much hot air. | Clogged or Failing Convection Fan | Unplug the stove. Clean the fan blades carefully. If the fan doesn’t spin freely or makes noise, it may need replacement. |

| Large, dark, and sooty flames in the burn pot. | Poor Fuel or High Feed Rate | Switch to a higher quality, low-ash wood pellet. Reduce the auger feed rate setting on your stove’s control panel. |

| Stove overheats randomly, even when clean. | Faulty High-Limit Switch or Thermocouple | Check wiring to the sensors. If the problem persists, the sensor may be faulty and need to be tested and replaced by a technician. |

| Noticeable “backpuffing” or smoke in the firebox. | Blocked Exhaust Vent | Immediately shut down the stove. The exhaust flue is severely blocked and requires immediate, thorough cleaning. |

Preventive Maintenance: How to Stop Overheating Before It Starts

The best way to fix an overheating problem is to prevent it from ever happening. Consistent maintenance is not optional; it’s a requirement for safe operation.

Creating a Regular Cleaning Schedule

Don’t wait for an error code. Create a routine. A light daily cleaning (scraping the burn pot), a more thorough weekly cleaning (vacuuming ash), and a deep monthly cleaning (checking fans and passages) can prevent 90% of all performance issues, including overheating.

Choosing the Right Pellets

Invest in high-quality pellets. While budget pellets might save you money upfront, they often contain more ash, bark, and moisture, which leads to clinkers and rapid soot buildup. This causes inefficiency and can lead to dangerous blockages.

Quality fuel is paramount. Unlike processed firewood where you might consider how many Duraflame logs to use for a specific burn time, pellet stoves require a consistent fuel source designed specifically for them. Store your pellets in a dry place to prevent them from absorbing moisture.

Annual Professional Servicing

Once a year, before the heating season begins, have your stove inspected and serviced by a certified technician. They can perform a comprehensive cleaning, inspect gaskets and seals, test electrical components, and ensure your stove is operating at peak safety and efficiency.

Advanced Troubleshooting and When to Call a Pro

If you have performed a deep clean and are still experiencing overheating, the issue may be more complex.

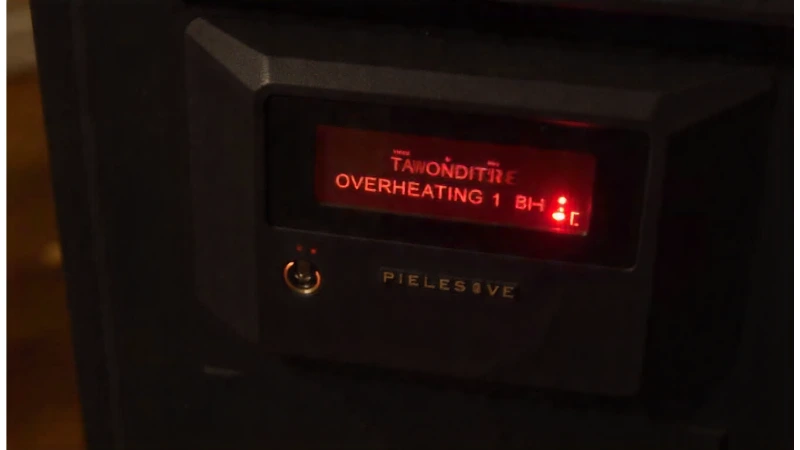

Understanding Error Codes

Your stove’s manual is your best friend. It will contain a list of error codes and their specific meanings. A high-temperature or high-limit error confirms overheating, but other codes might point toward a specific failing component, like a vacuum switch or an exhaust probe.

Electrical Safety and Your Stove

A pellet stove relies on a stable supply of electricity to power its fans, auger, and control board. Ensure the outlet it’s plugged into is in good condition and on a circuit that is not overloaded. Unstable power can damage the sensitive electronics.

It’s always wise to ensure your home’s entire electrical system is up to code, as outdated components can pose a risk. Knowing about historical issues, like learning what is the problem with Stab-Lok breakers, reinforces the importance of electrical safety inspections for your whole house, not just the appliance.

The Importance of Proper Ventilation

Never underestimate the importance of your stove’s flue. The principles of safe venting are universal across heating appliances. While the mechanics of a pellet stove’s forced exhaust differ from a wood stove or furnace, the fundamental need for a clear pathway for dangerous gases to exit is the same.

This core safety principle often brings up related questions for other appliances, such as whether does the flue need to be open for a pilot light on a gas fireplace, emphasizing that each system has specific venting requirements that must be followed.

If you’ve exhausted all the troubleshooting steps and your pellet stove overheating problem persists, it’s time to call a professional. Continuing to operate a malfunctioning stove is not worth the risk. A qualified technician has the diagnostic tools and expertise to safely identify and repair faulty sensors, motors, or control boards, giving you peace of mind and a warm, safe home.