Best Insulation Options for 2×3 Walls

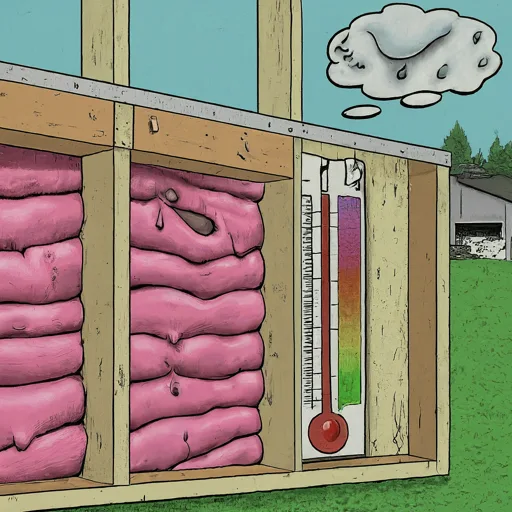

When it comes to insulating walls, the dimensions and structure of the wall cavity play a crucial role in determining the best type of insulation to use. For homes or buildings with 2×3 walls, choosing the right insulation can significantly affect energy efficiency, indoor comfort, and even the longevity of the building materials.

This article will explore the various insulation options available for 2×3 walls, considering their thermal performance, ease of installation, cost, and environmental impact.

You'll Learn About

Understanding 2×3 Wall Construction

What Are 2×3 Walls?

2×3 walls are constructed using studs that are 2 inches by 3 inches in size, typically used in non-load bearing walls, interior partitions, and sometimes in exterior walls of older buildings.

These walls are not as deep as the more common 2×4 walls, providing less space for insulation. This limitation necessitates careful selection of insulation materials to maximize thermal performance within the confined space.

Challenges with 2×3 Walls

The primary challenge with 2×3 walls is the reduced cavity depth, which restricts the amount of insulation that can be installed. This limitation can impact the R-value, a measure of thermal resistance, making it essential to choose high-performance insulation materials.

Why the Best Insulation is Needed?

Building a home or renovating an existing one involves countless decisions, and choosing the right insulation for your walls is a crucial one. 2×3 wall construction, commonly used for non-load-bearing interior walls and sometimes exterior walls in warmer climates, requires careful consideration when it comes to insulation.

While it might seem like any insulation is better than none, selecting the best option for your specific needs can significantly impact your home’s comfort, energy efficiency, and overall value.

Here’s why understanding the best insulation options for your 2×3 walls is essential:

1. Energy Efficiency and Cost Savings:

Proper insulation acts as a barrier, keeping the desired temperature inside your home. In the summer, it prevents heat from penetrating, reducing your reliance on air conditioning. Conversely, in the winter, it traps the warm air inside, minimizing the need for heating. This translates to significant energy savings on your utility bills.

2×3 walls, compared to thicker framed walls, have less inherent insulating power. Choosing the best insulation option for these walls becomes even more important to achieve optimal temperature control and maximize efficiency.

2. Improved Comfort:

Beyond energy savings, proper insulation directly impacts your home’s comfort level. Poorly insulated walls allow unwanted heat transfer, making it challenging to maintain a consistent and comfortable temperature. In the summer, your home might feel warm and stuffy, while winters can be uncomfortably cold.

Choosing the right insulation for your 2×3 walls ensures a more consistent and comfortable living environment throughout the year.

3. Noise Reduction:

Insulation doesn’t just regulate temperature; it also plays a role in soundproofing. 2×3 walls, due to their thinner profile, offer less inherent soundproofing compared to thicker walls. Selecting the right insulation type can significantly reduce noise transmission between rooms and from outside sources. This is especially crucial for bedrooms, home offices, or if you live in a noisy neighborhood.

4. Moisture Control and Mold Prevention:

Properly insulated walls contribute to managing moisture levels within your home. Insulation acts as a barrier, preventing condensation from forming on the interior surfaces of the walls. This condensation can lead to mold growth, which can be detrimental to your health and property.

Choosing the right insulation with proper vapor barrier installation helps control moisture levels and prevent mold issues.

5. Increased Home Value:

Energy efficiency and comfort are high priorities for potential home buyers. A well-insulated home with lower energy bills and a comfortable living environment can be a significant selling point. Investing in the best insulation options for your 2×3 walls can ultimately increase your home’s value when you decide to sell.

Now, let’s explore the different insulation options for 2×3 walls and how to choose the best one for your needs:

Types of Insulation for 2×3 Walls:

- Fiberglass Batts: The most common and budget-friendly option. Fiberglass batts are easy to install and come in various thicknesses and R-values (a measure of thermal resistance). However, their effectiveness can be compromised by improper installation, air gaps, and settling over time.

- Rigid Foam Board Insulation: This type offers high R-value per inch and good moisture resistance. Rigid foam boards come in various thicknesses and are installed directly on the exterior of the studs. However, they can be more expensive than fiberglass batts and require precise cutting for a proper fit.

- Spray Foam Insulation: Provides excellent air sealing and soundproofing due to its ability to fill all gaps and crevices. Spray foam boasts a high R-value per inch and good moisture resistance. However, it requires professional installation, is the most expensive option, and can be messy during the application process.

Choosing the Best Insulation for Your Needs:

Several factors influence which insulation option is best for your 2×3 walls:

- Climate: Consider your local climate. Colder climates require higher R-value insulation to prevent heat loss. Conversely, warmer climates might prioritize moisture resistance.

- Space Limitations: 2×3 walls offer less cavity space for insulation. Consider the thickness of the insulation and ensure it doesn’t significantly impact your interior space.

- Cost: Fiberglass batts are the most affordable option, while spray foam is the most expensive. Weigh the cost against the R-value, ease of installation, and other benefits offered by each type.

- DIY vs. Professional Installation: Some options, like fiberglass batts, can be DIY-friendly, while others like spray foam require professional installation. Consider your skills and budget when making your choice.pen_spark

Insulation Materials for 2×3 Walls

Fiberglass Batts

Overview

Fiberglass batts are one of the most common and cost-effective insulation materials. They are composed of fine glass fibers and come in pre-cut panels that fit between the studs.

Benefits

- Cost-Effective: Fiberglass batts are relatively inexpensive.

- Ease of Installation: They are easy to install, even for DIY projects.

- Fire-Resistant: Fiberglass is naturally fire-resistant.

Drawbacks

- Lower R-Value: Standard fiberglass batts for 2×3 walls typically offer an R-value of about R-10 to R-11.

- Potential for Gaps: Improper installation can leave gaps, reducing effectiveness.

Spray Foam Insulation

Overview

Spray foam insulation is a high-performance option that expands upon application to fill cavities, providing an airtight seal.

Benefits

- High R-Value: Closed-cell spray foam can achieve R-values of R-6 to R-7 per inch, maximizing thermal resistance within the limited space.

- Air Sealing: Provides excellent air sealing, reducing drafts and improving energy efficiency.

- Moisture Barrier: Acts as a barrier to moisture, reducing the risk of mold and mildew.

Drawbacks

- Cost: Spray foam is more expensive than other insulation types.

- Professional Installation: Typically requires professional installation, adding to the cost.

Rigid Foam Insulation

Overview

Rigid foam insulation panels, such as extruded polystyrene (XPS), expanded polystyrene (EPS), or polyisocyanurate (Polyiso), provide high R-values and are suitable for 2×3 walls.

Benefits

- High R-Value: Polyiso can provide an R-value of up to R-6.5 per inch.

- Moisture Resistance: Resistant to moisture, reducing the risk of mold.

- Structural Support: Adds some structural support to walls.

Drawbacks

- Cost: Generally more expensive than fiberglass batts.

- Installation Complexity: Can be more challenging to install in irregular cavities.

Mineral Wool Insulation

Overview

Mineral wool, also known as rock wool, is made from molten rock or industrial waste materials spun into fibers.

Benefits

- Fire Resistance: Highly fire-resistant, withstanding temperatures up to 1,800°F.

- Sound Absorption: Excellent soundproofing qualities.

- Moisture Resistance: Does not absorb water, reducing the risk of mold.

Drawbacks

- Lower R-Value: Offers an R-value of about R-4 per inch, which may not be sufficient for very cold climates.

- Weight: Heavier than other insulation materials, which can complicate installation.

Comparing Insulation Options for 2×3 Walls

To help you decide the best insulation for your 2×3 walls, here’s a comparative table summarizing the key aspects of each type:

| Insulation Type | R-Value per Inch | Cost | Ease of Installation | Moisture Resistance | Fire Resistance | Sound Absorption |

|---|---|---|---|---|---|---|

| Fiberglass Batts | R-3.1 to R-4.3 | Low | Easy | Moderate | High | Moderate |

| Spray Foam (Closed-Cell) | R-6 to R-7 | High | Difficult | High | High | Moderate |

| Rigid Foam (Polyiso) | R-6.5 | Moderate | Moderate | High | Moderate | Low |

| Mineral Wool | R-4 | Moderate | Moderate | High | Very High | High |

Best Practices for Insulating 2×3 Walls

Maximizing Thermal Performance

- Seal Gaps and Cracks: Before installing insulation, ensure all gaps and cracks are sealed with caulk or expanding foam to prevent air leaks.

- Vapor Barriers: In climates with significant temperature differences, consider adding a vapor barrier to prevent moisture buildup within the walls.

- Layering Insulation: Combining different types of insulation can enhance thermal performance. For example, using a thin layer of spray foam for air sealing followed by fiberglass batts can offer a good balance of cost and efficiency.

Installation Tips

- Precision Cutting: Ensure that insulation batts or panels are cut precisely to fit snugly between studs without compression.

- Professional Installation: For materials like spray foam or if you’re unsure about the installation process, hiring a professional can ensure optimal performance and safety.

- Safety Gear: Always use appropriate safety gear, such as gloves, goggles, and masks, when handling insulation materials to protect against irritation and inhalation of fibers or chemicals.

Environmental Considerations

Eco-Friendly Insulation Options

If sustainability is a priority, consider these eco-friendly insulation options:

- Cellulose Insulation: Made from recycled paper products, cellulose insulation is an environmentally friendly option. It offers good thermal performance (R-3.6 to R-3.8 per inch) and excellent soundproofing qualities.

- Cotton Batts: Made from recycled cotton (often denim), these batts are non-toxic and biodegradable, providing an R-value of around R-3.5 per inch.

Reducing Environmental Impact

- Recycled Content: Opt for insulation materials with high recycled content to reduce environmental impact.

- Local Sourcing: Where possible, source materials locally to reduce the carbon footprint associated with transportation.

- Energy Efficiency: Properly installed insulation improves energy efficiency, reducing the need for heating and cooling and, consequently, lowering carbon emissions.

Conclusion

Choosing the right insulation for 2×3 walls involves balancing thermal performance, cost, ease of installation, and environmental impact.

Fiberglass batts offer an affordable and easy-to-install solution but may not provide the highest R-value. Spray foam insulation, while more costly, delivers superior thermal resistance and air sealing capabilities. Rigid foam panels and mineral wool provide other options with their own sets of advantages.

Ultimately, the best insulation for your 2×3 walls will depend on your specific needs, climate, and budget. By understanding the characteristics of each insulation type and following best practices for installation, you can enhance the comfort and energy efficiency of your building while minimizing environmental impact.

Insulating 2×3 walls requires materials that maximize space and efficiency. Consider using rigid foam boards or spray foam. For more insulation tips, explore our articles on the thinnest R30 insulation options and R-30 insulation for 2×8 walls. If you’re tackling other home improvements, like running wires through a brick fireplace, proper planning ensures energy efficiency.