Why Use 3/4 Drywall? Full Specs and Installation

You’re standing in the aisle of a big-box hardware store, staring at stacks of drywall. You see plenty of 1/2-inch and 5/8-inch boards, but the 3/4-inch drywall you need for your project is nowhere in sight. This frustrating search is a common problem for homeowners and contractors alike.

This specialty board isn’t a standard stock item for a reason. Its weight, cost, and specific applications mean you have to know where to look. This guide will end your search and provide the roadmap to finding, purchasing, and properly using 3/4-inch drywall for your project.

You'll Learn About

Why Is 3/4-Inch Drywall So Elusive?

Finding 3/4-inch drywall feels like a treasure hunt because it’s a niche product designed for specific, heavy-duty applications. Unlike the standard 1/2-inch panels that line the walls of most homes, 3/4-inch board is built for performance. Its primary purpose is to enhance fire resistance and sound control.

This beefy board is most commonly required in commercial buildings, multi-family dwellings like apartments and condos, and specific residential areas like furnace rooms or home theaters. Because the demand is lower and more specialized, most major home improvement retailers don’t keep it in stock. They focus on high-volume products, leaving the specialty items to dedicated suppliers.

The Key Differences: Understanding Drywall Thickness

The thickness of drywall directly impacts its strength, fire resistance, and sound-dampening capabilities. Standard 1/2-inch drywall is perfectly adequate for most interior walls. For ceilings and walls requiring a fire rating, 5/8-inch Type X drywall is often the go-to choice.

A single layer of 3/4-inch drywall, however, can often provide a fire-resistance rating that would otherwise require multiple layers of thinner drywall. This increased density also makes it a formidable barrier against sound transmission, which is why it’s favored for spaces where noise control is critical.

Your Roadmap: Where to Find 3/4 Drywall Near You

You won’t likely find 3/4-inch drywall next to the paint swatches at your local big-box store. The secret is to look where the professionals shop. Here’s your definitive guide to locating this hard-to-find material.

Stop Here First: Local Building and Drywall Suppliers

Your number one destination should be a dedicated building supply company or a specialty drywall supplier. These businesses cater to professional contractors and are far more likely to stock specialized materials like 3/4-inch panels. A quick search for “drywall supplier near me” or “building materials supplier” will yield better results than searching for a specific retail chain.

When you call, be specific. Ask for “three-quarter-inch, Type X, fire-rated drywall” to ensure you get the right product. These suppliers often offer delivery services, which is a massive advantage given the weight of these panels.

The Pro Desk: Your Secret Weapon at Big-Box Stores

While the regular aisles may disappoint, don’t give up on big-box stores entirely. Head straight to the Pro Desk. The staff there can check inventory across their entire supply chain and place a special order for you.

Be prepared for potential minimum order quantities and longer lead times. However, if other options fail, this is a reliable way to get the materials you need. It’s a lesser-known service that bridges the gap between consumer retail and professional supply.

Leverage Professional Knowledge: Ask a Contractor

Local drywall contractors have an intimate knowledge of the regional supply chain. They know exactly who stocks what and where to get the best prices. Don’t hesitate to reach out to a local professional for advice.

Many contractors are willing to point you in the right direction. In some cases, if you only need a few sheets, they might even sell you some directly from their own stock if they have leftovers from a larger job.

Before You Buy: Critical Factors to Consider

Once you’ve located a supplier, there are a few crucial details to sort out before you finalize your purchase. This isn’t your average drywall, and it requires special consideration for transportation, handling, and installation.

The Unspoken Challenge: Weight and Transportation

Do not underestimate the weight of 3/4-inch drywall. A single 4×8 sheet can weigh around 90 pounds or more, with larger 4×12 sheets tipping the scales at well over 100 pounds. This is not a one-person job. Ensure you have a vehicle capable of handling the weight and dimensions, and always bring help for loading and unloading.

For larger projects, delivery is almost always the best option. The extra cost is well worth avoiding the physical strain and potential for injury or damage to the material.

Understanding the Cost Factor

Specialty materials come with a higher price tag. Expect to pay a premium for 3/4-inch drywall compared to its thinner counterparts. The benefits of superior fire resistance and soundproofing often justify the cost, but it’s essential to budget accordingly.

The table below provides a general comparison of common drywall types. Prices can vary significantly based on your location and supplier, so always get a direct quote.

| Drywall Thickness | Approx. Weight (4×8 Sheet) | Average Cost per Sheet | Primary Use Case |

|---|---|---|---|

| 1/2″ Standard | 50-60 lbs | $12 – $18 | Standard interior walls and ceilings |

| 5/8″ Type X | 70-80 lbs | $16 – $25 | Ceilings, garages, fire-rated walls |

| 3/4″ Type X | 90-115 lbs | $20 – $35+ | High-performance fire resistance, soundproofing |

Framing and Fastener Adjustments

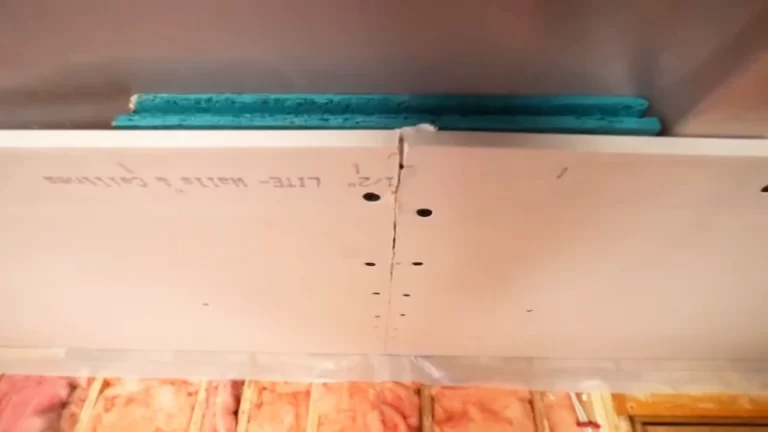

The good news is that standard wood or steel framing is typically sufficient to support the weight of 3/4-inch drywall. The critical adjustment you must make is with your fasteners. Standard drywall screws will be too short.

You will need to use longer screws, generally 2 inches or more, to ensure they penetrate the drywall and securely anchor into the framing studs. Using screws that are too short is a significant safety risk, as the heavy panels could detach from the wall or ceiling.

Is 3/4-Inch Drywall the Right Choice for Your Project?

Before committing to this heavy-duty material, it’s worth asking if it’s truly necessary for your application. While its properties are impressive, there may be alternative solutions that are easier to source and install.

If you’re unsure if 3/4 drywall is the right choice, consider its primary applications. It excels in creating fire-rated assemblies, such as the separation wall between a house and an attached garage or between units in a multi-family building. It is also a top-tier choice for soundproofing home theaters, recording studios, or walls adjacent to noisy areas.

For soundproofing, alternatives like resilient channels, double layers of 5/8-inch drywall, or sound-dampening compounds like Green Glue can also provide excellent results. These methods might be more accessible and easier for a DIYer to handle than wrestling with extremely heavy 3/4-inch panels.

Installation Tips for Heavy-Duty Drywall

Handling and installing 3/4-inch drywall requires more muscle and a few specific techniques. Safety and proper methods are paramount to achieving a professional and secure finish.

A Non-Negotiable Tool: The Drywall Lift

For ceiling installations, a drywall lift is not a luxury; it’s a necessity. Attempting to lift and hold a 100-pound panel overhead while trying to drive screws is dangerous and nearly impossible. You can rent a drywall lift from most tool rental centers for a reasonable daily rate.

Cutting Requires More Effort

The standard “score and snap” method still works, but it requires significantly more pressure and a very sharp utility knife blade. To effectively cut the thick drywall, make several firm passes with your knife to score it deeply before attempting to snap the board. A drywall rasp is useful for smoothing any rough edges after the cut.

Secure Fastening is Everything

Proper fastening is crucial for a safe installation. Drive screws every 12 inches in the field of the panel and every 8 inches along the seams. Ensure each screw head is sunk just below the paper surface without tearing it, creating a “dimple” that can be easily filled with joint compound.

Your Search is Over

While finding 3/4-inch drywall near you requires looking beyond the usual places, it is far from impossible. By targeting specialty building suppliers, leveraging the Pro Desk at big-box stores, and consulting with local contractors, you can source this high-performance material for your project.

Remember to plan for its significant weight and adjust your installation techniques accordingly. With the right knowledge and preparation, you can confidently tackle any project that calls for the superior strength, fire resistance, and soundproofing of 3/4-inch drywall.