What Is The Difference Between Conveyor And Feeder

Conveyors are often overloaded with feed material, leading to decreased throughput and increased costs. Speed variably conveyors can increase the production rate by adjusting their speed on-the-fly according to demand.

Feeders that operate at a constant speed tend to be more efficient than those that variably operate due to their fixed speeds, but this comes with a price tag. Variable conveying devices have the ability to change their output speeds in order for them accommodate varying amounts of material being conveyed at any given time

You'll Learn About

What Is The Difference Between Conveyor And Feeder?

When transferring a large number of birds to their feeders, be sure to use a feeder that is Flood-Loaded. Conveyors aren’t speed-varying and can move the feeder at a constant speed so you don’t have to watch it constantly.

By variably operating conveyors, you are able to adjust their movement according to your needs or the bird population in your area. Feeders with variable speeds will keep all birds fed without having them wait in line for too long.

Feeders Are Flood-Loaded

Feeders are stocked with products and dispensed by a conveyor belt, while feeders are flood-loaded, typically used for distributing pet food or birdseed in an enclosed area.

The main difference between the two types of feeders is how they’re loaded and dispensed: a conveyor-loaded feeder moves product down a chute; while a flood-loaded feeder is filled with seed and water before it’s opened to the birds or pets.

It’s important to choose the right type of feeder for your needs – whether you need one that’s easy to use or one that will handle large amounts of product quickly and efficiently. You can find both types of feeder at most major retailers, so don’t hesitate to explore all your options before settling on one.

Keep in mind that different animals will require different feeding habits – if you have any questions about what kind offeeder would be best suited for your feathered friends, consult with an expert first.

Conveyors Aren’t Speed Varying

Conveyors are machines that move materials, either continuously or intermittently, while feeders provide a controlled flow of material to the machine. A conveyor belt moves items down an incline whereas a feeder sends individual pieces of material directly to the machine’s output without any interference from other objects.

The advantage of using a conveyor over a feeder is that it can handle more weight and produce products at faster speeds with less wear on the machinery. Conveyors also tend to be quieter than Feeders because they don’t create as much noise when operating; however, this isn’t always true depending on the type of conveyor being used.

When selecting a conveying system for your business, keep in mind its intended use and how often it will be used to minimize downtime and maximize production

Feeders Operate At A Constant Speed

Feeders move products at a constant speed, whereas conveyors can vary the speed depending on the product. This makes feeders better for moving small items or delicate produce.

They’re also more efficient since they don’t waste time and energy stopping and starting like conveyors do. You’ll be able to achieve consistent production with feeders compared to conveyors that can have fluctuations in output due to their varied speeds.

Because of this, feeders are typically used in industrial settings where consistency is key when it comes to producing goods

Conveyors Can variably Operate

Conveyors are a more efficient way of moving materials across a manufacturing line or between different parts of an industrial plant. Feeders typically move smaller items, like raw material into the production process and products out onto the marketplace.

They can be used in conjunction with conveyors to increase productivity by consolidating multiple tasks into one area of the factory floor. They may also be used as standalone units for single-task operations such as product delivery or material handling.

Conveyors offer many potential benefits over feeder systems including fewer employee injuries and less wasted time due to slower movement times.

What is a feeder conveyor?

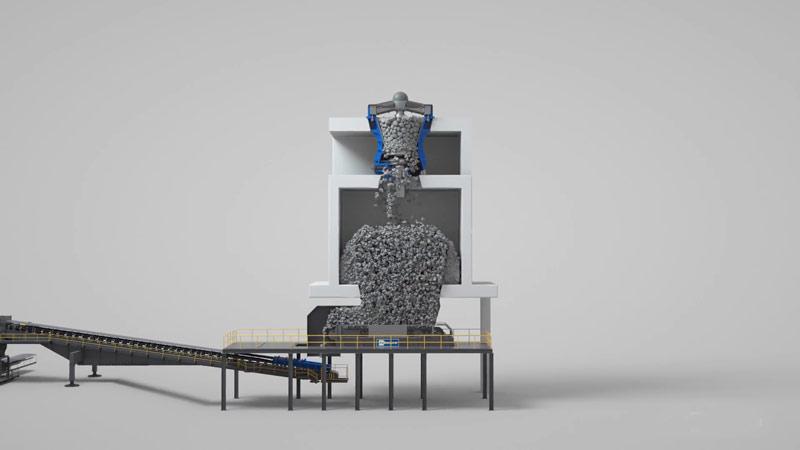

A feeder conveyor is a type of machine that feeds materials into another machine, such as a manufacturing line. It uses chains or belts to move the material forward and helps speed up the process.

A conveyor feeder is a machine that is used to move materials from one location to another on an assembly line. They are typically used on industrial machinery and equipment, where they can be very useful in moving parts and products together quickly and efficiently.

There are a variety of different types of conveyor feeders available, each with its own specific features and applications.

Is feeder a component of belt conveyor?

Feeders are components of belt conveyors that help move material along the conveyor. They’re usually made out of metal, and they attach to the belt itself.

The feeder supplies material to the belt, and it allows the material to move smoothly down the conveyor.

- A belt feeder is a component of a conveyor system that helps to increase throughput by feeding material directly onto the belt.

- Belt feeders are usually located over the conveyors and collect material from an area below it before delivering it to the conveyor for processing.

- Vertical strike-off plates control how much of the incoming load is allowed on top of the moving belt, resulting in controlled movement down the line.

What is belt feeder?

A belt feeder is a machine that is used to introduce material into a system at a controlled rate. It can handle a variety of materials and applications, reliable and useful in an endless amount of applications.

Belt feeders are often reliable machines for various tasks such as printing, coating or dispensing powders, etc., making them essential in many industries today

What is feeder in mechanical engineering?

A feeder is a major component in mechanical engineering and its function varies depending on the type of machine it’s used in. These control the flow of bulk material by moving it to where it needs to go and can be adjusted depending on the need.

Feeders come in many different shapes, sizes, and materials; some are even movable. There are various types available for specific machines, so choose wisely based on your needs.

How many types of feeders are there?

There are a few types of feeders, each with its own advantages and disadvantages. hydrostatic feeders use water pressure to move food, while Archimedes screws work with the force of gravity.

pneumatic feeders use air pressure to dispense food. centrifugal feeders rotate food in a central chamber, and gravity-fed systems rely on the gravitational pull of objects to move it toward an animal or person.

What conveyor belt is used for?

Belt conveyors are used to transporting products in a straight line or through changes in elevation or direction. Belt conveyors are good for gentle slopes and curves, but can also be used for materials that require more stringency, like grains, ore, coal, etc.

Belts can be made from rubber or metal depending on the application. There are different types of belt conveyors based on their intended use:

- rubber-belted conveying belts for foods and liquids;

- metal-belted conveying belts for heavy loads such as rocks and construction debris;

- continuous belt systems where material moves continuously over a wide surface area;

- chain drive with idler pulleys which move the product at a walking pace across an area of less than 400 sq ft (37m2) per minute;

- parallel motion chains moving goods at faster speeds up to 2 miles per hour (3km/h)

How many types of conveyor belts are there?

Conveyor belts come in three types: basic belt conveyors, snake sandwich belts, and long belt conveyors. Basic belt conveyors are motorized or require manual effort to operate; snake sandwich belts have several pulleys that hold the material together, and long belt conveyors are generally used for raw material handling.

Each type of conveyor has its own advantages and disadvantages depending on the application. It is important to understand the characteristics of each type of conveyor before making a purchase so you can choose one that will suit your needs best

How do conveyor belts work?

Conveyor belts are a common sight in factories and elsewhere. They’re used to move large objects, like eggs or flour, around a factory. Conveyor belts work by moving the object along the belt at a constant speed.

Conveyor belts to move material around

The belts are made of sturdy materials and have motors that help to keep them moving. The belt is stretched out on one side by the use of pulleys, which then spin at the same speed. This keeps the belt moving in one direction while it moves across the surface that you are wanting to reach.

What is a weigh feeder?

A weigh feeder is a type of agricultural machine that feeds grain into large mills or crushers. It works by moving the grain forward and down, so it can be weighed and measured.

Controls the Flow of Material Very Accurately

A weigh feeder is a device that controls the flow of material very accurately. This system is automated, so you don’t have to worry about any complicated procedures or settings. The weight feeder can be used in many industrial applications, such as manufacturing and agriculture.

Controller and Different Instruments to Control the Flow

The controller uses different instruments to control the flow of materials through the machine, ensuring that it operates smoothly and efficiently all time. You can also use this system from a distance, making it easy for you to oversee your work area without having to get up close and personal with the machine itself.

The Process Can Be Controlled from a Distance

Weight feeders are often equipped with sensors that allow you to set thresholds for various parameters such as speed or pressure. This allows you to keep an eye on your process while still being able to operate the machine autonomously from a distance if necessary.

To Recap

Conveyor and feeder systems move products or materials along a linear path by using an automated system. Feeders are used to distribute material to several different points on the conveyor belt, while conveyors can be used for more complex tasks such as moving parts between two locations.