Conduit for Water Heater – Wearing Water Heater Properly

Water heaters are an essential component in any household, providing hot water for daily activities such as cooking, cleaning, and bathing. To ensure the safe and efficient operation of these appliances, proper electrical wiring is necessary.

This includes the use of conduit, a protective casing that surrounds and protects electrical wires. The purpose of water heater conduit is to protect the electrical wiring that powers the water heater and prevent electrical hazards such as fires and electrical shock.

In this article, we will discuss the importance of conduit in electrical wiring, the purpose of water heater conduit, and provide an overview of the different types of conduit available.

You'll Learn About

Nec Requirements for Water Heater Conduit

Water heaters are essential appliances in every home, providing hot water for daily needs such as showering, cleaning, and cooking. As a result, proper electrical wiring is critical to ensure safety and reliability of these systems. The National Electrical Code (NEC) provides guidelines for the installation of electrical wiring, including requirements for water heater conduit.

Types of Conduit Approved by the Nec

The NEC recognizes several types of conduit, including metal conduit, non-metallic conduit, and flexible conduit. Metal conduit is commonly used for outdoor installations and is made of materials such as steel or aluminum.

Non-metallic conduit is typically made of plastic and is commonly used in indoor installations. Flexible conduit is made of a flexible material and is often used in tight spaces or where there is a need for movement.

Minimum Conduit Size Requirements

The NEC specifies minimum conduit size requirements based on the wire size and number of conductors. For example, for a wire size of 10 gauge and a single conductor, the minimum conduit size is 1/2 inch.

For a wire size of 12 gauge and two conductors, the minimum conduit size is 3/4 inch. It is important to consult the NEC to determine the appropriate conduit size for a specific installation.

Protection Against Physical Damage

Water heaters can be subject to physical damage, such as from impacts or crushing. To protect against such damage, the NEC requires that conduit be installed so as to provide protection against physical damage. This may include installing conduit in a protected area or using conduit with a thicker wall thickness to provide added protection.

the NEC provides specific guidelines for the installation of water heater conduit to ensure safety and reliability of electrical wiring. It is important for professionals to follow these guidelines to ensure proper installation and avoid potential hazards. By understanding the requirements for conduit size, type, and protection against physical damage, professionals can ensure a safe and effective installation of water heaters.

Choosing the Right Type of Water Heater Conduit

Water heaters require electrical wiring for power and safety, and to protect the wiring from physical damage and moisture, it is important to use conduit. There are several types of conduit available, each with its own set of advantages and disadvantages. Understanding these different types of conduit can help you choose the best option for your water heater.

Rigid Metal Conduit (RMC) Rigid metal conduit (RMC) is a heavy-duty, galvanized steel conduit that is commonly used in commercial and industrial applications. It provides excellent protection against physical damage and has a long lifespan.

RMC is typically more expensive than other types of conduit, but it offers a higher level of protection and durability. This makes it an ideal choice for water heaters located in areas with high levels of physical damage or exposure to moisture.

Intermediate Metal Conduit (Imc)

Intermediate metal conduit (IMC) is a lighter-duty alternative to RMC, but it still provides good protection against physical damage. IMC is typically made from galvanized steel, and it is less expensive than RMC. It is a popular choice for residential and light commercial applications, and it is often used for water heaters located in less demanding environments.

Flexible Metal Conduit (Fmc)

Flexible metal conduit (FMC) is a flexible, corrugated steel conduit that is ideal for applications where conduit needs to be bent around tight corners or curves. FMC is often used in applications where conduit is exposed to vibration or movement, such as in water heaters located in mobile homes. While it provides good protection against physical damage, it is not as durable as RMC or IMC, and it may not be suitable for all applications.

Factors to Consider When Choosing the Right Type of Conduit

When choosing the right type of conduit for your water heater, there are several factors to consider. These include:

- The level of protection required against physical damage and moisture

- The location of the water heater and the potential for exposure to moisture or physical damage

- The cost of the conduit and the budget for the project

- The flexibility and ease of installation required for the project.

Choosing the right type of conduit for your water heater is important to ensure the safety and longevity of your electrical wiring. Consider the factors mentioned above and consult with a professional electrician to help you make an informed decision.

Installing Water Heater Conduit

Before installing the conduit for your water heater, it is important to plan and prepare properly. This involves determining the best route for the conduit and considering any obstacles that may need to be worked around.

It’s important to know the total length of conduit needed so you can purchase the right amount of materials. You’ll also want to make sure you have all of the necessary tools, such as a conduit cutter, conduit bender, conduit hangers, electrical box, and screws.

Measuring and Cutting the Conduit

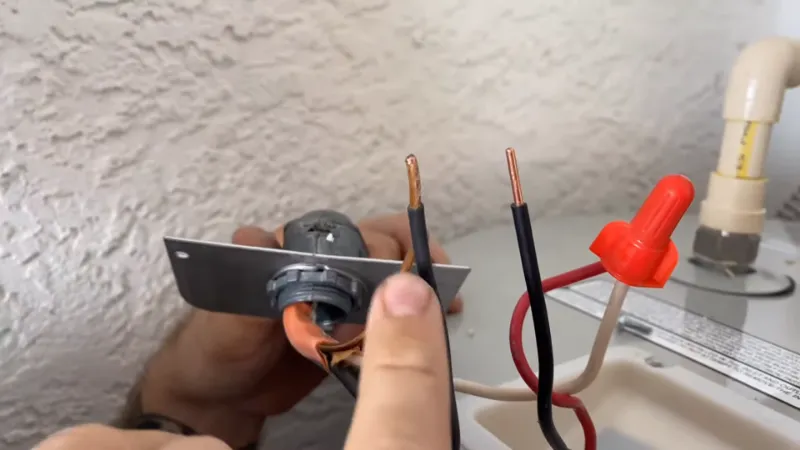

Once you’ve planned and prepared, it’s time to measure and cut the conduit. Start by measuring the distance between the electrical panel and the water heater. Cut the conduit to the correct length using a conduit cutter.

If the conduit needs to be bent, use a conduit bender to make the necessary adjustments.

Securing the Conduit to the Wall

Next, secure the conduit to the wall using conduit hangers or clamps. It’s important to choose hangers or clamps that are appropriate for the type of conduit you’re using and that are rated for the weight of the conduit and its contents. Make sure to install the hangers or clamps in the right location so that the conduit won’t interfere with anything else.

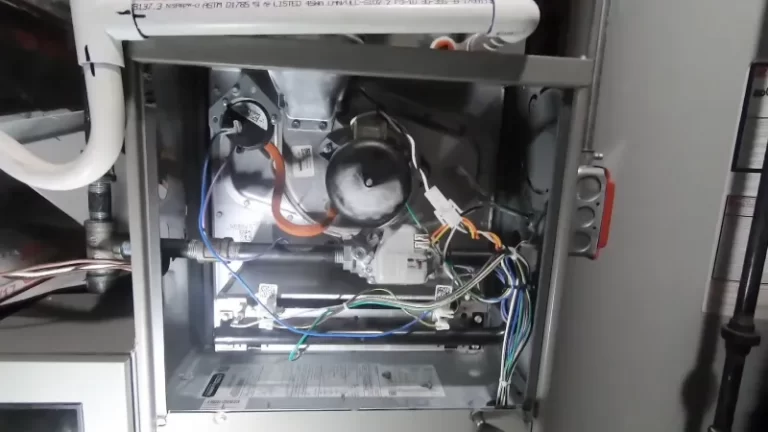

Connecting the Conduit to the Water Heater

Once the conduit is secured to the wall, it’s time to connect it to the water heater. This is done using a fitting that is appropriate for the type of conduit you’re using. The fitting should be securely fastened to the water heater and the conduit should be attached to the fitting.

Connecting the Conduit to the Electrical Panel

Finally, connect the conduit to the electrical panel. This is done by installing a conduit fitting on the electrical panel and connecting the conduit to the fitting. Make sure to tighten the connection properly so that the conduit is securely fastened to the panel.

It’s important to use a fitting that is appropriate for the type of conduit you’re using and that is rated for the weight of the conduit and its contents.

Installing water heater conduit requires proper planning, preparation, and execution to ensure that the conduit is properly secured and connected. By following these steps, you can help ensure that your water heater is properly wired and protected.

Comparison of Different Types of Conduit for Water Heater Installation

| Conduit type | Characteristics | Advantages | Disadvantages |

|---|---|---|---|

| Rigid Metal Conduit (RMC) | Heavy-duty steel | Durable, fire-resistant | Difficult to bend and install |

| Intermediate Metal Conduit (IMC) | Steel with a thinner wall than RMC | Lighter than RMC, easy to bend | Not as fire-resistant as RMC |

| Flexible Metal Conduit (FMC) | Corrugated metal tubing | Easy to bend and route around obstacles | Not as durable as RMC or IMC |

When it comes to installing a water heater, choosing the right type of conduit is important to ensure a safe and efficient electrical system. Rigid metal conduit (RMC) is a heavy-duty steel conduit that is extremely durable and fire-resistant.

However, it can be difficult to bend and install. Intermediate metal conduit (IMC) is a lighter alternative to RMC, made of steel with a thinner wall. IMC is easier to bend than RMC, but is not as fire-resistant.

Finally, flexible metal conduit (FMC) is a corrugated metal tubing that is easy to bend and route around obstacles, but is not as durable as RMC or IMC.

When choosing the right type of conduit for your water heater installation, consider the specific needs of your project. If you need a durable, fire-resistant conduit, RMC may be the best option. If you need a lighter, more flexible conduit, IMC or FMC may be better suited for your needs.

Consider the specific requirements of your installation, such as the length of the conduit, the location of the water heater, and the access to the electrical panel. With careful consideration, you can choose the right type of conduit to ensure a safe and efficient water heater system.

Tips and Tricks for Installing Water Heater Conduit

Water heaters are essential components of any home, and the electrical wiring used to power them must be installed correctly and safely. The conduit used to protect the electrical wires from damage and fire hazards is a critical part of the installation process. In this section, we will provide tips and tricks to help ensure that your water heater conduit installation is successful.

Keep Conduit Away From Heat Sources

One of the most important tips for installing water heater conduit is to keep it away from heat sources. This is because high temperatures can cause the conduit to expand, contract, and even warp, which can cause damage to the electrical wires and create a fire hazard. To avoid this, always install the conduit at least six inches away from heat sources such as the water heater, furnace, and stove.

Use Conduit Hangers to Secure the Conduit to the Wall

Conduit hangers are an essential part of the conduit installation process because they help secure the conduit to the wall. These hangers are designed to be easy to install and provide a stable and secure attachment point for the conduit. They also help to protect the conduit from physical damage, such as bending or crushing, and provide an added layer of protection for the electrical wires.

Use Conduit Fittings to Make Turns and Changes in Direction

Conduit fittings are used to make turns and changes in direction when installing conduit. These fittings come in various sizes and styles and allow you to bend the conduit without damaging it. They also help to reduce the risk of physical damage to the electrical wires and provide a smooth transition between different sections of conduit.

Use Conduit Sealants to Prevent Water and Air From Entering the Conduit

Conduit sealants are used to prevent water and air from entering the conduit and damaging the electrical wires. These sealants are typically applied at the ends of the conduit and around any fittings to provide a tight, water-resistant seal. They are an important part of the conduit installation process and help to ensure that your water heater and electrical wiring are protected against damage and hazards.

The installation of water heater conduit is an important part of the electrical wiring process. By following these tips and tricks, you can ensure that your installation is safe, secure, and compliant with NEC requirements. If you are unsure about any part of the installation process, it is always best to consult with a professional electrician for guidance and assistance.

Why Should You Choose the Right Conduit?

A water heater conduit is a critical component in ensuring a safe and efficient electrical system for your water heater. By choosing the right type of conduit and properly installing it, you can protect your electrical wiring from physical damage and prevent water and air from entering the conduit.

From rigid metal conduit to flexible metal conduit, each type has its own unique features and benefits. It is important to consider factors such as the location of the water heater and the environment it is located in when choosing the right type of conduit.

Proper installation is equally important, as it ensures that the conduit is securely fastened to the wall and connected to both the water heater and electrical panel. To achieve the best results, it is recommended to follow NEC requirements, use conduit hangers, fittings, and sealants, and keep the conduit away from heat sources.

Whether you are a DIY enthusiast or a professional, it is essential to understand the importance of a water heater conduit and the steps involved in its installation.

What is the Role of Conduit in a Water Heater System?

Conduit plays a critical role in the electrical wiring of a water heater system. It acts as a protective covering for the electrical wires that connect the water heater to the electrical panel. The conduit helps to protect the wires from physical damage, moisture, and other environmental factors.

By using conduit, it helps ensure that the electrical wiring system is safe and up to code.

Why is It Important to Use the Right Type of Conduit for Your Water Heater System?

The type of conduit you choose for your water heater system can have a significant impact on its overall safety and efficiency. Different types of conduit are designed to provide different levels of protection and to meet different requirements.

For example, rigid metal conduit (RMC) provides the highest level of protection but is also the most rigid and difficult to install. On the other hand, flexible metal conduit (FMC) is easier to install but offers less protection.

Choosing the right type of conduit for your water heater system will ensure that it is safe, efficient, and meets all local electrical codes.

What Are the Nec Requirements for Water Heater Conduit?

The National Electric Code (NEC) sets specific requirements for the type and size of conduit used in a water heater system. The NEC specifies that metal conduit must be used and that it must be at least the minimum size required to accommodate the electrical wires used in the system.

The NEC also requires that the conduit be protected against physical damage and that it be properly grounded. By following these requirements, you can help ensure that your water heater system is safe and up to code.

What Factors Should You Consider When Choosing the Right Type of Conduit for Your Water Heater System?

There are several factors to consider when choosing the right type of conduit for your water heater system. These include the type of environment the conduit will be installed in, the size of the electrical wires that will be running through it, and the level of protection you want to provide for the electrical wires.

You should also consider the ease of installation and the overall cost of the conduit. By taking these factors into consideration, you can choose the right type of conduit for your water heater system.

How Do You Install Water Heater Conduit?

Installing water heater conduit is a relatively straightforward process, but it does require careful planning and preparation. The first step is to measure and cut the conduit to the correct length. Next, secure the conduit to the wall using conduit hangers.

Then, connect the conduit to the water heater and the electrical panel. Finally, use conduit fittings to make turns and changes in direction, and use conduit sealants to prevent water and air from entering the conduit.

By following these steps, you can install water heater conduit and help ensure that your water heater system is safe and efficient.

Additional Tips for Installing Water Heater Conduit

Plan the Route of the Conduit Carefully

When planning the route of the conduit, it’s important to consider several factors such as the location of the water heater, the electrical panel, and the path that provides the shortest distance between the two while avoiding any obstacles. Proper planning will not only save time but will also make the installation process smoother and more efficient.

Consider the Impact of Temperature on the Conduit

The temperature of the water heater and the surrounding environment can have a significant impact on the conduit. For example, PVC conduit should not be used in areas with high temperatures. As a result, it’s important to choose a conduit that is suitable for the temperature conditions in the area where the water heater is located.

Avoid Overloading the Circuit

It’s important to avoid overloading the circuit when installing a water heater conduit. Overloading the circuit can result in tripped breakers and even electrical fires. Before installing the conduit, it’s important to determine the maximum current capacity of the circuit and to ensure that the conduit is sized appropriately to handle the current.

Proper Labeling and Documentation

Proper labeling and documentation is important for the safety and efficiency of the water heater conduit. Labeling the conduit at both ends and near any changes in direction helps to identify the conduit in case of any maintenance or repair work. It’s also important to keep detailed documentation of the installation process, including the materials used, the size of the conduit, and any other relevant information.

By following these additional tips and tricks, you can ensure that your water heater conduit is installed properly and safely. A well-installed conduit system will provide reliable electrical service to your water heater, improving its efficiency and helping to prevent any potential electrical issues.

Final Words

The NEC (National Electrical Code) requires that electrical wiring be protected by conduit in certain circumstances, such as in areas where it may be subjected to physical damage. Flexible metal conduit, or EMT, is a commonly used type of conduit for electrical wiring, and it can be used to protect the wiring for your electric hot water heater. If you’re not sure if flexible metal conduit is NEC-compliant, it’s best to consult with a licensed electrician or check the NEC requirements for your specific location.

As for fastening the conduit to the wall, there are several methods that can be used, including using conduit clamps or conduit hangers. These devices can be attached to the wall and used to secure the conduit in place, ensuring that it doesn’t slip out of the opening. Additionally, some conduit clamps or hangers can be adjusted to accommodate different wall thicknesses, making them versatile and suitable for a wide range of applications.

In regards to the installation of the electric hot water heater, it’s important to follow proper electrical safety procedures and to have a basic understanding of electrical wiring and conduit installation. If you’re unsure about any aspect of the installation, it’s best to consult with a licensed electrician to ensure that the installation is done safely and in accordance with local electrical codes.