Sump Pump Never Runs? Don’t Wait for a Flood, Read This!

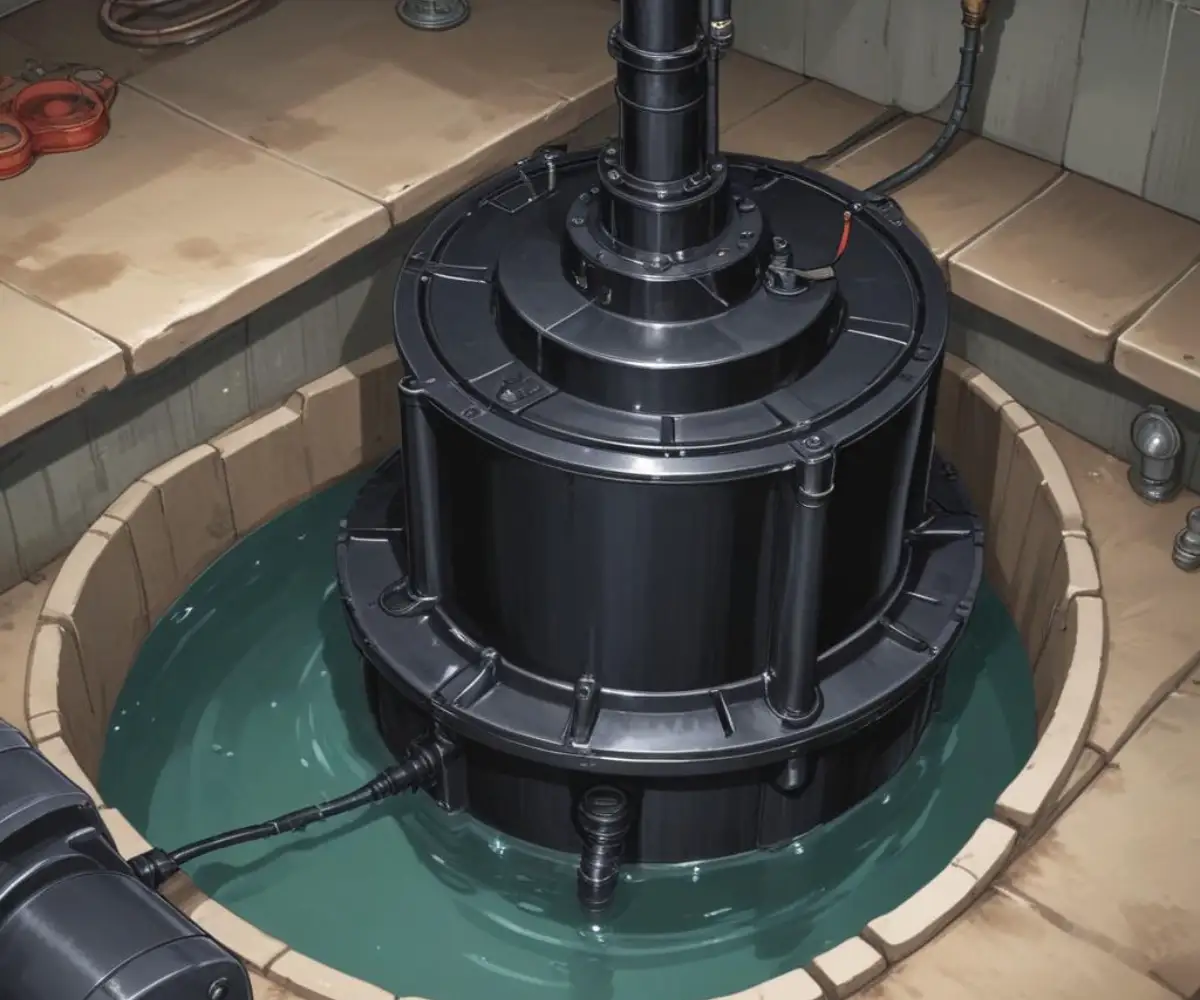

You walk down to your basement during a heavy rainstorm, expecting to hear the familiar, reassuring hum of your sump pump kicking on. Instead, you’re met with silence. The water level in the sump pit is rising, and a knot of panic tightens in your stomach. A sump pump that never runs is a disaster waiting to happen.

Ignoring a silent sump pump is a gamble you can’t afford to take. A single basement flood can cause thousands of dollars in damage, ruin irreplaceable belongings, and create a hazardous mold problem. Understanding why your sump pump isn’t working is the first critical step to protecting your home.

You'll Learn About

Why Is My Sump Pump Not Turning On? Uncovering the Silent Culprits

When your sump pump fails to activate, it’s usually due to one of several common issues. From simple power problems to mechanical failures, pinpointing the exact cause is key. Let’s break down the most frequent reasons your pump might be sitting idle when you need it most.

1. Power Supply Problems: The Most Common Failure Point

Before assuming the worst, always start with the most obvious culprit: the power source. Sump pumps are electrical appliances, and a disruption in power is a frequent reason for them to stop working. This is especially common during severe storms when power outages are likely.

First, check if the pump is securely plugged into its outlet. It might seem too simple, but vibrations can sometimes loosen the plug. Next, inspect the circuit breaker or fuse box. A tripped breaker or a blown fuse will cut power to the pump. If you find a tripped breaker, reset it once. If it trips again immediately, you have a more serious electrical issue that requires a professional electrician. Also, ensure the pump is on a dedicated circuit to prevent overloading. Plugging other appliances into the same circuit can cause it to trip. It’s also crucial that the sump pump is plugged into a Ground Fault Circuit Interrupter (GFCI) outlet, which can also trip and cut power.

2. A Failed or Stuck Float Switch: The Pump’s Achilles’ Heel

The float switch is one of the most critical components of your sump pump system. It acts as the trigger, telling the pump when to turn on and off as the water level in the sump pit rises and falls. If this switch malfunctions, your pump won’t activate, no matter how high the water gets.

Float switches can fail in several ways. Debris in the sump pit can physically obstruct the float, preventing it from rising with the water. The float can also get wedged against the side of the basin. Over time, the mechanical components of the switch can simply wear out and fail. If you notice your sump pump only works when you shake it, this is a strong indicator of a failing float switch. It’s often possible to replace just the switch, which is less expensive than replacing the entire pump.

3. Clogged Pump and Impeller: When Debris Halts Operation

Your sump pit can collect more than just water. Dirt, gravel, sediment, and other small debris can get washed in. If this debris gets sucked into the pump, it can clog the intake screen or jam the impeller. The impeller is the spinning component that propels water out of the pit. A jammed impeller will stop the motor from running, which can lead to overheating and motor burnout if not addressed.

Regularly cleaning your sump pit is essential preventative maintenance. If you suspect a clog, you’ll need to disconnect the pump from power and the discharge pipe, remove it from the pit, and inspect the intake and impeller. Clearing away any obstructions can often restore its function. A whining or humming noise from the motor without any water being pumped is a classic sign of a jammed impeller.

4. A Blocked or Frozen Discharge Pipe

The pump’s job is to move water from the pit to the outside of your home through a discharge pipe. If this pipe is blocked, the water has nowhere to go. This back-pressure can strain the motor and prevent it from running properly. In colder climates, the discharge line is highly susceptible to freezing, creating an impassable ice plug.

You should inspect the end of the discharge line outside your home to ensure it’s free of dirt, leaves, snow, or other blockages. The pipe should extend at least 20 feet away from your foundation to prevent water from cycling back. If you live in an area with freezing winters, having a specialized freeze-resistant discharge line installed can prevent ice blockages.

A Step-by-Step Guide to Troubleshooting Your Silent Sump Pump

When you discover your sump pump isn’t running, don’t panic. Follow these logical steps to diagnose and potentially fix the issue yourself. Safety first: always unplug the sump pump from its power source before performing any hands-on inspection or maintenance.

Step 1: Verify the Power Source

Start with the simplest solutions. Check that the pump is firmly plugged in. Test the GFCI outlet by pressing the “TEST” and then “RESET” buttons. Look at your home’s electrical panel for a tripped circuit breaker. If the outlet has power and the breaker is on, the problem lies elsewhere.

Step 2: Inspect the Float Switch

With the pump unplugged, look inside the sump pit. Can the float switch move freely? Remove any debris that might be blocking its path. Gently lift the float by hand. You should hear a “click” as it engages the switch. If it feels stuck or doesn’t move smoothly, it may be the source of the problem.

Step 3: Test the Pump Motor Directly

You can bypass the float switch to test the motor itself. Many pumps have a “piggyback” plug where the pump’s plug goes into the back of the float switch’s plug. Unplug them from each other and plug the pump’s cord directly into the GFCI outlet. If the motor kicks on, you know the pump works and the float switch is the faulty component. Do not run the pump dry for more than a few seconds, as this can damage the motor.

Step 4: Manually Test with Water

If the motor runs when plugged in directly, plug it back into the float switch and into the outlet. Slowly pour a 5-gallon bucket of water into the sump pit. This should raise the float and trigger the pump to turn on. If the pump activates and clears the water, the system might be working correctly. However, an intermittent issue with the float switch could still be present.

Preventative Maintenance: The Key to a Reliable Sump Pump

The best way to deal with a sump pump failure is to prevent it from happening in the first place. Regular, simple maintenance can dramatically extend the life of your pump and ensure it’s ready for the next storm. Perform these checks at least once a year, or seasonally if your pump runs frequently.

Start by cleaning the sump pit. Unplug the pump, remove it from the basin, and use a wet/dry vacuum to clear out all water, mud, and debris. Clean the pump’s intake screen. While it’s out, inspect the check valve on the discharge line. This one-way valve prevents water from flowing back into the pit after the pump shuts off. A faulty check valve can cause the pump to cycle too often, leading to premature failure. Make sure the arrow on the valve is pointing in the direction of water flow, away from the pump.

| Problem Symptom | Potential Cause | DIY Solution / Professional Help |

|---|---|---|

| Pump is completely silent, no sound at all. | No power, burned-out motor. | Check plug, GFCI, and circuit breaker. If power is confirmed, the motor may be dead (professional replacement needed). |

| Pump hums but doesn’t pump water. | Jammed impeller, clogged discharge line. | Unplug pump. Check for and clear debris from impeller and intake. Inspect discharge line for blockages. |

| Water level is high, but pump won’t turn on. | Stuck or failed float switch. | Ensure float can move freely. Test motor by plugging it in directly. If motor runs, replace the float switch. |

| Pump runs, but water doesn’t clear from pit. | Faulty check valve, air lock, or leak in discharge line. | Inspect check valve for proper operation. Ensure weep hole is clear to prevent air lock. Check for visible leaks. |

| Pump turns on and off very frequently. | Faulty/stuck check valve, undersized pump, or high water table. | A constantly cycling pump can be a sign of backflow. If your sump pump runs every 10 seconds, it may indicate a serious issue needing professional assessment. |

When to Call a Professional Plumber

While many common sump pump issues can be resolved with basic troubleshooting, some problems require the expertise of a licensed plumber. If you’ve gone through the basic checks and the pump still won’t run, it’s time to call for help. Electrical issues beyond a simple tripped breaker should always be handled by a professional to avoid the risk of shock or creating a fire hazard.

If you discover the motor is burned out or the pump has reached the end of its typical 7-10 year lifespan, a professional can recommend and install the correct size and type of replacement pump for your home’s needs. Attempting a complex repair or replacement yourself can sometimes lead to bigger problems, like an improper installation that fails during the next downpour. The cost of a professional repair, which can range from $300 to $750, is a small price to pay for the peace of mind that comes with a properly functioning flood prevention system.

Protecting Your Investment: Backup Systems and Final Checks

The most common reason for a sump pump to fail is a power outage during a storm—exactly when you need it most. A battery backup sump pump is your best defense against this scenario. These secondary pumps are installed alongside your primary pump and will automatically take over if the power goes out, providing hours of protection until electricity is restored.

Remember, your sump pump is a silent guardian for your basement. Don’t let its silence become a sign of neglect. Regular testing and maintenance are crucial. If you’re hearing strange noises or notice your sump pump is running but you still hear water, it could be an early warning sign of failure. By understanding the common causes of failure and knowing how to troubleshoot them, you can ensure your home stays dry, safe, and protected from the devastating effects of water damage.