Stud Finder Not Consistent? Your Ultimate Guide to Why & How to Fix It

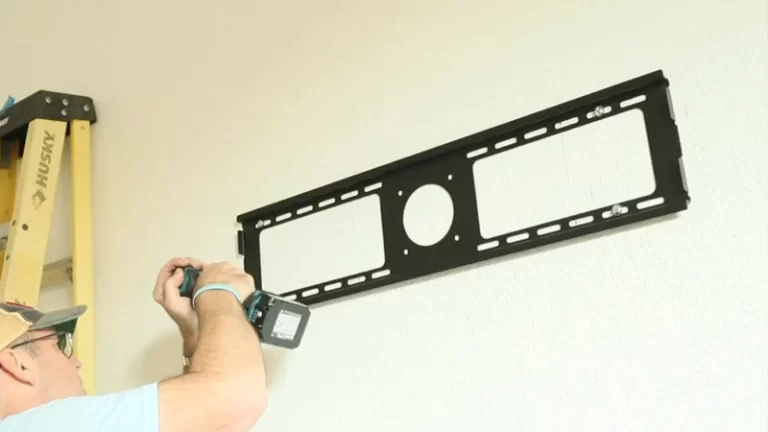

You have a project, a heavy mirror to hang, a new flat-screen TV to mount, or shelves to install. You grab your stud finder, ready to locate that solid wood framing, but instead of clear, confident beeps, you get chaos. It beeps in one spot, then goes silent on the next pass. It claims a “stud” is five inches wide, or it detects nothing at all. This frustration is a common roadblock for DIYers and can quickly turn a simple project into a wall full of confusing pencil marks and uncertainty.

An inconsistent stud finder is more than just an annoyance; it’s a potential safety hazard. Mounting heavy objects securely to wall studs is non-negotiable. This guide will demystify why your stud finder is giving you unreliable results and provide actionable, expert-level solutions to help you find studs accurately and consistently every single time.

You'll Learn About

Decoding the Deception: Why Your Stud Finder Is Lying to You

Before you can fix the problem, you must understand the source of the inconsistency. Electronic stud finders work by detecting changes in density behind your wall. When you calibrate it, you’re telling the device, “This is what an empty wall feels like.” As you slide it, it looks for an increase in density—the stud. However, several factors can disrupt this process, leading to false positives and missed targets.

The Human Element: Are You Using It Correctly?

Often, the problem isn’t the tool but the technique. Electronic stud finders are sensitive instruments, and simple mistakes can throw them off completely. Moving the device too quickly across the wall is a common error; a slow, steady pace is crucial for an accurate reading. Another frequent mistake is lifting or tilting the finder even slightly during a scan, which breaks the calibration and skews the results. Always keep the stud finder perfectly flat against the wall.

Calibration is perhaps the most critical step. If you accidentally calibrate the device over or even near a stud, it will register that higher density as “normal.” Consequently, it will fail to detect that stud and any others as you scan. Always begin in a spot you believe is hollow, several inches away from where you expect a stud to be.

The Wall Itself: Hidden Complexities and Obstructions

Not all walls are simple sheets of drywall over wooden studs. The construction and condition of your walls play a massive role in a stud finder’s performance. Older homes, for instance, often feature plaster and lath walls. This construction, with its wooden strips (lath) and inconsistent blobs of plaster, presents a density nightmare for electronic finders, often rendering them useless.

Even in modern homes, issues like thick or multi-layered drywall can exceed a standard stud finder’s scanning depth. Textured surfaces, like “popcorn” or knockdown finishes, can also create air gaps between the scanner and the wall, leading to inconsistent readings. For any major home project, understanding your wall’s composition is a vital first step, just as important as deciding between flooring materials like LifeProof vs. NuCore for a renovation.

Behind the Drywall: The Unseen Interference

The space between your walls isn’t always empty. A host of materials can trick your stud finder into giving a false positive, making you think you’ve found a stud when you haven’t. These hidden culprits are often the source of the most maddening inconsistencies.

Pipes (both metal and plastic), electrical wiring, and metal conduit are common obstructions that a stud finder might read as a stud. Foil-backed insulation or metal firebreaks can also create large areas of interference that confuse the device. It’s critical to be aware of potential hazards like live electrical wires; troubleshooting these issues requires the same caution as diagnosing why there’s no power to your thermostat.

The Tool’s Limitations: Is Your Stud Finder Up to the Task?

Finally, the issue might be the stud finder itself. Weak or old batteries are a primary cause of poor performance and should always be the first thing you check. A low battery can prevent the sensor from getting a strong, clear reading, leading to erratic behavior.

The quality and type of stud finder also matter. Basic models may lack the sensitivity or features needed for challenging walls. If you consistently face issues, it might be time to consider a more advanced tool that can better handle the specific conditions of your home.

From Frustration to Precision: How to Achieve Consistent Stud Finding

Now that you understand the potential causes, you can adopt a systematic approach to get reliable results. The key is to combine proper technique with a deeper understanding of what’s behind your wall. Don’t just hunt for a single point; aim to map the entire structure.

Mastering the “Art” of the Scan: A Step-by-Step Guide

Achieving consistency starts with a flawless technique. Follow these steps for every scan to dramatically improve your accuracy.

1. Install a Fresh Battery: Always start with a new, high-quality alkaline battery. This simple step eliminates the most common cause of stud finder problems.

2. Prepare the Surface: If your wall has a heavy texture, try placing a thin piece of cardboard over the area to create a smoother surface for the scanner to glide across.

3. Calibrate Correctly: Place the stud finder flat against the wall. Press and hold the power button until the device signals it’s calibrated (usually with a beep or a flash). Do not move it during this process.

4. Scan Slowly and Deliberately: While holding the power button, slide the device horizontally across the wall at a slow, steady pace. Do not rush.

5. Mark Both Edges: When the finder indicates a stud, don’t just mark one spot. Mark the leading edge where it first beeps. Continue sliding until the signal stops, and then scan back from the other direction to mark the other edge. The center of these two marks is the center of your stud.

6. Map the Wall: Don’t stop after finding one stud. Most residential framing uses studs spaced 16 or 24 inches apart on-center. Use a tape measure to find the next likely stud locations and confirm them with your scanner. This helps verify your findings and identify any irregular spacing.

Choosing the Right Tool for the Job

Not all stud finders are created equal. Understanding the different types can help you select a tool that matches the challenges of your home. A better tool can make all the difference, especially on tricky surfaces.

| Stud Finder Type | How It Works | Best For | Potential Downsides |

|---|---|---|---|

| Magnetic | Uses a powerful magnet to detect the metal screws or nails that fasten the drywall to the studs. | Plaster and lath walls; simple, foolproof verification. | Can be slow; only finds fasteners, not the full stud edges. |

| Electronic (Edge-Finding) | Senses changes in wall density to locate the edges of studs. | Basic drywall applications. | Requires marking both edges; can be prone to interference. |

| Electronic (Center-Finding) | Uses multiple sensors to pinpoint the center of the stud directly. | Most common DIY tasks; fast and efficient. | Can still be confused by pipes or wires close to the stud. |

| Multi-Scanner / Advanced | Combines density scanning with metal detection (for pipes/conduit) and AC wire detection. Often includes a “deep scan” mode. | Older homes, thick walls, and projects where avoiding pipes/wires is critical. | More expensive; can be overly sensitive if not used correctly. |

Verifying Your Findings: How to Be Absolutely Sure

Even with a great tool and perfect technique, it’s wise to verify a stud’s location before drilling, especially when hanging something heavy. A false positive could be a water pipe or electrical conduit, and drilling into those can be a costly mistake.

First, think logically. Studs are typically vertical members that run from floor to ceiling. If your finder detects an object that seems to run horizontally, it’s more likely a pipe or firebreak. A standard stud is 1.5 inches wide; if your readings indicate something much wider or narrower, be suspicious.

The classic “knock test” is a simple and effective verification method. Tap along the wall with your knuckle. The space between studs will produce a hollow, resonant sound, while tapping on a stud will sound solid and dull. This auditory feedback can quickly confirm or deny what your electronic finder is telling you.

When Stud Finders Fail: Reliable Alternative Methods

Sometimes, particularly with plaster and lath or other challenging walls, an electronic stud finder just won’t work consistently. In these cases, you can turn to several tried-and-true manual methods to locate framing.

The Power of Magnets

A strong rare-earth (neodymium) magnet can be your best friend. Tie it to a piece of string and drag it slowly across the wall. When it passes over a drywall screw or nail head, the magnet will stick. Since these fasteners are driven into studs, a vertical line of “sticking” points will reveal the stud’s location. This is often the most reliable method for plaster walls.

Using Your Eyes and Logic

Your house provides clues to its own construction. Look at the baseboards for small, filled nail holes, which often indicate where the trim was nailed into a stud. Similarly, electrical boxes for switches and outlets are almost always mounted to the side of a stud. You can often tell which side by looking inside the box.

Another trick is to use a bright flashlight. Hold it flat against the wall and shine the beam across the surface at a shallow angle. This technique can reveal subtle imperfections, like the slight dimples or bumps where drywall screws were mudded over, giving you a visual map of the fasteners and, by extension, the studs. It’s a simple trick for locating a secure point for your project, even if you are just hanging lightweight items like Christmas lights that don’t need a plug.

The Last Resort: Exploratory Drilling

If all else fails and you must be certain, you can use a very small drill bit (1/16″) to drill an exploratory hole where you believe a stud is. If you meet firm resistance after passing through the drywall (typically 1/2″ to 5/8″ thick), you’ve hit wood. If the bit pushes through easily into a hollow cavity, you’ve missed. These tiny holes are easy to patch with a dab of spackle.

By combining a better understanding of your tool with these verification techniques and alternative methods, you can conquer the challenge of an inconsistent stud finder. Patience, a systematic approach, and a willingness to cross-reference your results will ensure your next project is anchored safely and securely to the hidden framework of your home.