Sonopan USA: Your Ultimate Fix for Unwanted Noise is Here

Incessant noise is more than just an annoyance; it’s a major disruption to modern life. Whether it’s the sound of traffic, noisy neighbors, or just the general clamor of a busy household, unwanted sound can impact everything from your sleep to your ability to concentrate.

Many homeowners and builders feel stuck, believing that effective soundproofing is either too expensive or too complicated. You’ve tried different things, but the noise always seems to find a way through. This is where a specialized solution becomes not just a luxury, but a necessity.

Enter Sonopan, a high-performance soundproofing panel that has been a secret weapon for Canadian builders for years and is now making its mark in the USA. This isn’t just another layer of material; it’s an engineered solution designed to absorb and deaden sound in a fundamentally different way.

You'll Learn About

What Exactly is Sonopan and Why Should You Care?

The core problem with noise is that it travels in waves of varying frequencies. Low-frequency sounds, like the bass from a home theater or the rumble of a truck, are notoriously difficult to block with traditional building materials. This is the challenge Sonopan was designed to overcome.

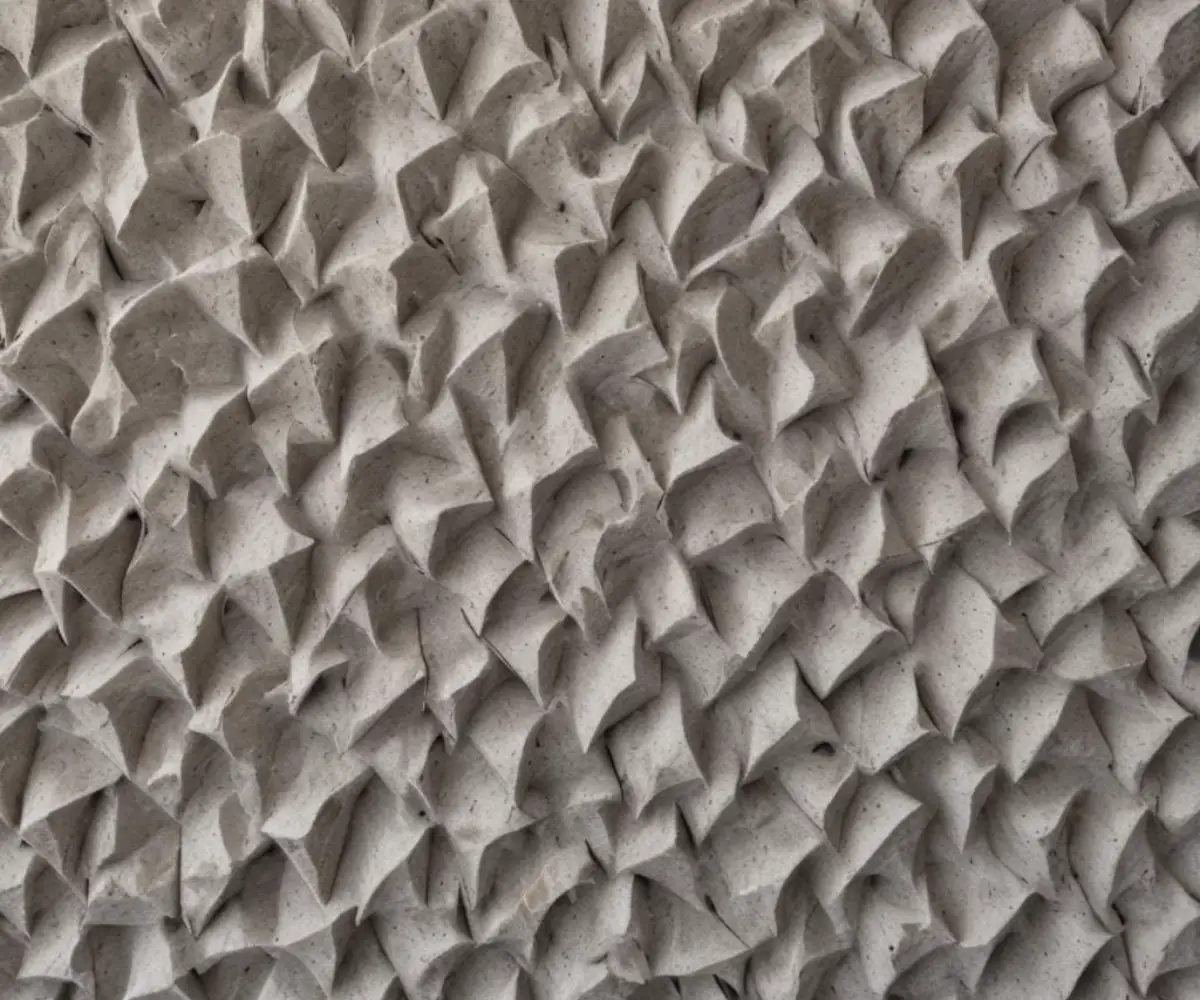

Sonopan is an eco-friendly panel made from 100% recycled wood fibers. What makes it unique is its patented Noise STOP Technology. During manufacturing, each panel is stamped with over 17,000 impressions of varying depths and sizes, creating an uneven density across the board.

This innovative design allows the panel to absorb a much wider range of sound frequencies, especially those pesky low-frequency sounds below 125 Hz that pass through other materials. It’s a lightweight, non-toxic, and effective barrier against the sounds that disrupt your peace.

The Failure of Standard Construction: Why Your Walls Are Like Drums

Think of a standard wall assembly as a drum. It consists of two sides of drywall stretched over a frame of wood studs. When sound waves hit one side, they cause the drywall to vibrate, transferring the sound through the studs to the other side, which then vibrates and projects the sound into your room.

While standard drywall provides mass, it does little to stop this vibrational energy transfer. This is a key battleground in the ongoing drywall vs drop ceiling soundproofing debate, where simply adding more of the same material yields diminishing returns. A dedicated sound-absorbing layer is needed to break this cycle.

Sonopan works by adding a crucial middle layer that absorbs these vibrations before they can travel through the structure. It fundamentally changes the wall from a sound transmitter into a sound absorber, creating a significantly quieter environment on the other side.

A Deeper Look: The Science Behind Sonopan’s Sound Absorption

The effectiveness of Sonopan lies in its unique structure. The thousands of impressions on each side of the panel create a variety of densities. When sound waves encounter these different densities, their energy is disrupted and converted into tiny amounts of heat, effectively deadening the sound.

This is different from simply adding mass, which is what happens when you install multiple layers of drywall. While mass is important for blocking airborne sound, absorption is critical for stopping a wide range of frequencies and preventing sound from echoing within the wall cavity itself.

This process is particularly effective for dealing with everyday noises. Whether you’re trying to contain the sound of a home theater, create a quiet home office, or simply stop hearing conversations from the next room, Sonopan’s absorption capabilities offer a robust solution.

Your Step-by-Step Guide to a Quieter Home: Installing Sonopan

One of the most appealing aspects of Sonopan is its ease of installation. A standard 4’x8′ panel weighs only about 26 pounds, making it manageable for a single person. Here’s a guide to integrating it into your project.

Step 1: Preparation is Key

Before you begin, ensure your wall or ceiling framing is complete and any insulation, like fiberglass or mineral wool batts, is installed within the stud cavities. For best results, always use insulation alongside Sonopan. Gather your tools: a circular saw or utility knife, drywall screws, and high-quality acoustic sealant.

Step 2: Cutting the Panels

Sonopan panels can be easily cut to size using a circular saw for a fast, clean cut. You can also use a sharp utility knife, but make sure to cut all the way through the panel. Do not score and snap the panels like you would with drywall, as this can damage the compressed wood fibers.

Step 3: Mounting the Panels

Install the Sonopan panels directly onto the wood studs or ceiling joists. You can also install them over existing drywall in a retrofit project. Fasten the panels using 1 5/8″ drywall screws, placing them about every 12 inches along the perimeter and in the center of the panel.

Step 4: The Most Important Step: Sealing the Gaps

Sound is like water; it will find any crack or gap to leak through. This is why sealing is non-negotiable. Apply a continuous bead of acoustic sealant around the entire perimeter of each Sonopan panel and where the panels meet each other. This creates an airtight seal that prevents sound flanking.

Step 5: Finishing with Drywall

Sonopan is not a finished wall surface and must be covered with drywall. For optimal performance, use 5/8″ thick drywall instead of the standard 1/2″ variety, as the added mass will further improve sound blocking. For even better results, consider using resilient channels between the Sonopan and the drywall to decouple the layers and stop more vibration.

Sonopan vs. Other Soundproofing Methods: The Ultimate Showdown

When planning a soundproofing project, you’ll encounter various products and techniques. Understanding how Sonopan stacks up against the alternatives is crucial for making an informed decision. Each method has its pros and cons, but Sonopan often provides a balanced and highly effective solution.

| Feature | Sonopan | Mass Loaded Vinyl (MLV) | Green Glue Compound | Double 5/8″ Drywall |

|---|---|---|---|---|

| Primary Function | Sound Absorption & Blocking | Sound Blocking (Mass) | Vibration Damping | Sound Blocking (Mass) |

| Eco-Friendliness | Very High (100% recycled wood) | Low (Synthetic material) | Moderate (Water-based polymer) | Moderate (Recyclable gypsum) |

| Installation Ease | Easy (Lightweight panels) | Difficult (Heavy, floppy rolls) | Moderate (Messy application) | Moderate (Heavy lifting) |

| Cost-Effectiveness | High | Low (Very expensive) | Moderate (Adds labor and material cost) | High (Material is cheap) |

| Low-Frequency Performance | Excellent | Good | Excellent | Fair |

Also Read: How Long After Rain to Stain a Fence? The Critical Wait Time

The Hidden Advantage: Thermal Performance and Energy Savings

While Sonopan is celebrated for its acoustic properties, it offers a significant secondary benefit that is often overlooked: thermal insulation. The compressed wood fiber structure gives a single panel an R-value of approximately 2.45. This can be a game-changer for your home’s energy efficiency.

When you add Sonopan to your walls or ceilings, you’re not just creating a sound barrier; you’re also adding a layer of insulation. This helps keep your home warmer in the winter and cooler in the summer, potentially reducing your heating and cooling costs over time.

This dual-purpose functionality makes the investment in Sonopan even more valuable. Unlike purely synthetic soundproofing materials like Mass Loaded Vinyl, Sonopan contributes to the overall thermal performance of your home, making your space more comfortable in every sense of the word.

Common Pitfalls and How to Avoid Them

Even the best materials can fail if installed incorrectly. When working with Sonopan, be sure to avoid these common mistakes to ensure you get the maximum soundproofing benefit from your efforts.

1. Skipping the Acoustic Sealant

We cannot stress this enough: unsealed gaps will compromise your entire soundproofing assembly. A tiny crack can let a surprising amount of sound through. Take the time to meticulously seal every seam and perimeter edge.

2. Using Sonopan as a Standalone Product

Sonopan is designed to be part of a system. It must be covered by drywall. Installing Sonopan without a final layer of dense material over it will not provide the expected results for blocking airborne noise.

3. Forgetting About Flanking Paths

Sound doesn’t just travel through walls; it can also go around them through floors, ceilings, ductwork, and outlets. For critical applications like a home theater, you must also consider treating these “flanking paths” to achieve true sound isolation. Even the best wall won’t help if the noise is coming through the vents.

Bringing Peace and Quiet Home

Noise pollution is a problem you no longer have to live with. With its innovative design, eco-friendly composition, and proven effectiveness, Sonopan offers a powerful and accessible solution for homeowners across the USA. It addresses the core issue of sound transmission in a way that traditional materials simply can’t.

By absorbing sound waves and breaking the chain of vibration, Sonopan helps you create dedicated quiet spaces, whether for work, relaxation, or entertainment. It’s a strategic investment in the comfort and tranquility of your home.

The next time you’re planning a renovation or new construction, look beyond standard drywall. Consider how adding a dedicated soundproofing layer like Sonopan can fundamentally improve your living environment. Your peace of mind is worth it.