Soffit Staple Gun Secrets: Stop Sagging & Secure Panels Like a Pro!

There’s nothing more frustrating than stepping back to admire your handiwork only to see sagging, wavy, or loose soffit panels. It’s a common problem that plagues many DIY enthusiasts and even some professionals. You spend hours on a ladder, cutting panels to perfection, only for the final result to look unprofessional and vulnerable to wind, moisture, and pests.

This widespread issue often stems from one critical mistake: using the wrong tool for the job. Many attempt to use a hammer and nails or an all-purpose heavy-duty stapler, leading to cracked vinyl, oversized holes, and fasteners that simply don’t have the holding power. The result is a weak installation that will inevitably fail, causing headaches and costly repairs down the road.

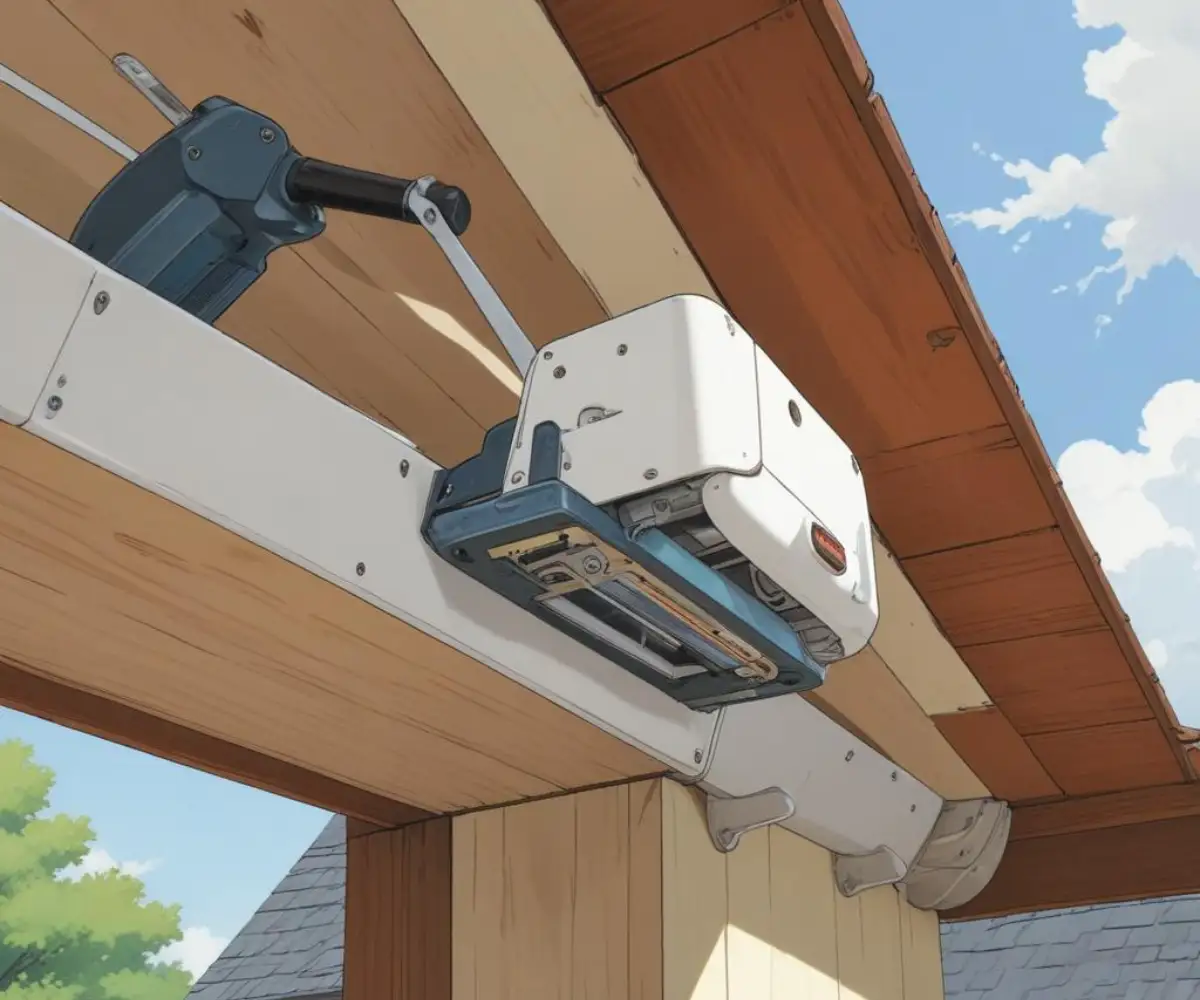

The solution lies in a specialized tool designed specifically for this task: the soffit staple gun. Using the right stapler with the correct type of staples is the secret to a fast, secure, and clean-looking installation that stands the test of time. This guide will walk you through everything you need to know to fix your soffit problems and achieve a professional, long-lasting finish.

You'll Learn About

Why Your Soffit Installation is Failing (and How to Fix It)

A flawless soffit installation does more than just boost curb appeal; it’s essential for proper attic ventilation and protecting your home’s rafters from weather and pests. Unfortunately, even a small mistake can lead to significant problems. Sagging panels, visible gaps, and moisture damage are often symptoms of an improper installation, and the root cause is almost always the choice of fastener and tool.

Using incorrect fasteners, like nails that are too short or staples that are the wrong type, is a primary culprit. These won’t adequately grip the underlying wood structure, allowing panels to loosen over time. Similarly, poor tool selection can cause damage during installation. A hammer can easily mar the surface of aluminum or crack delicate vinyl, while a standard staple gun lacks the precision needed, often driving fasteners too deep or leaving them proud.

The consequences of these failures extend beyond aesthetics. Gaps can invite birds, insects, and rodents to nest in your eaves, leading to damage and potential health hazards. Improperly secured panels can be ripped off by high winds, and moisture intrusion can lead to rot and mold in the roof structure. Fixing these issues starts with understanding that soffit materials require a fastening system that provides a strong hold without compromising the material itself.

Pneumatic vs. Electric: The Power Play

When selecting a soffit staple gun, the first major decision is the power source: pneumatic or electric. Each has distinct advantages and is suited for different types of projects.

Pneumatic staple guns are the choice of most professionals for a reason. Powered by an air compressor, they offer unmatched speed, power, and consistency. They can drive staples into dense wood framing with ease, ensuring a secure hold every time. Their lightweight construction (as the motor is in the separate compressor) reduces user fatigue, a significant benefit when working overhead for extended periods. However, they do require a cumbersome air hose, which can be challenging to manage on a ladder.

Electric and cordless staple guns offer incredible convenience and portability. Without the need for a compressor or hose, they are perfect for smaller repairs, quick jobs, or locations where power access is limited. While they are generally less powerful than pneumatic models, modern battery technology has made them a viable option for many applications. The main drawbacks are their heavier weight due to the onboard motor or battery and a slower firing rate, which can slow down large-scale projects.

The Crown Jewel: Why Narrow Crown Staples are Non-Negotiable

The single most important factor for a successful soffit installation is using narrow crown staples. These staples typically have a 1/4-inch crown (the top, flat part of the staple). This specific size is crucial because it fits perfectly within the nailing groove or hem of vinyl and aluminum soffit panels.

This precise fit allows the staple to secure the panel firmly without being visible on the finished surface. The two legs of the staple provide significantly more holding power than a single nail, preventing the material from tearing or pulling loose over time. Using staples with a wider crown would damage the panel by crushing the channel, while brad nails simply don’t offer enough surface area to hold the lightweight material securely against wind and expansion.

The ideal staple is 18-gauge, which is thin enough to penetrate easily without splitting the wood but strong enough to resist corrosion and hold fast. For longevity, especially in coastal or humid climates, always choose galvanized or stainless steel staples to prevent rusting and unsightly stains on your soffit.

Key Features to Look For in a Soffit Stapler

Beyond the power source, several key features distinguish a great soffit staple gun from a mediocre one. Paying attention to these details will make your work easier, safer, and more professional.

Adjustable Depth Control is arguably the most critical feature. It allows you to fine-tune how deep the staple is driven, which is essential to prevent over-driving and blasting right through the soffit material. You want the staple set snugly, but not so tight that it restricts the natural expansion and contraction of vinyl panels.

A lightweight body, often made of aluminum or magnesium, is vital for reducing fatigue during overhead work. Look for a tool with an adjustable exhaust port that directs air away from your face and the work surface. Finally, a tool-free jam clearing mechanism is a massive time-saver, allowing you to quickly resolve the inevitable staple jam without needing extra tools.

The Pro’s Playbook: A Step-by-Step Guide to Using a Soffit Staple Gun

Having the right tool is half the battle; using it correctly is the other. Following a systematic approach will ensure a safe and flawless installation from start to finish. This step-by-step guide will walk you through the process like a seasoned professional.

Step 1: Safety First – Gearing Up for Success

Before you even think about firing a staple, prioritize your safety. Working overhead on a ladder comes with inherent risks, so proper preparation is non-negotiable. Always wear safety glasses to protect your eyes from debris and ricocheting fasteners.

Inspect your equipment thoroughly. If using a pneumatic stapler, ensure the air hose is free of cracks and the compressor is set to the manufacturer’s recommended pressure for your tool. Read the stapler’s manual to understand its specific safety features and operation before you begin.

Step 2: Prep Work is Key – Setting the Stage

Proper preparation of the work area is crucial for a smooth installation. Ensure that your receiving channels (like J-channel or F-channel) are securely fastened to the wall and the fascia board. These channels will hold the edges of your soffit panels in place.

Load your staple gun with the correct fasteners. For most vinyl or aluminum soffit, this means 18-gauge, 1/4-inch narrow crown staples that are long enough to penetrate at least 3/4 of an inch into the solid wood framing. Before installing your first panel, test your stapler on a scrap piece of soffit to perfectly calibrate the depth setting. The staple should be flush with the material, not countersunk or left sticking out.

Step 3: The Art of Fastening – Technique Matters

With your preparation complete, you can begin installing the soffit panels. Cut your first panel to length, allowing for a small gap for expansion, and insert it into the receiving channels. The key to a secure installation is to place the staples correctly.

Position the tip of the staple gun directly in the center of the panel’s nailing groove. This ensures the staple holds the panel without being visible. Fasten the soffit panel into the solid wood framing behind it, placing a staple every 12 to 16 inches. Always keep the stapler flush against the surface to ensure the staples drive in straight, providing maximum holding power.

| Fastener Type | Best For | Pros | Cons |

|---|---|---|---|

| 1/4″ Narrow Crown Staples (18-Gauge) | Vinyl & Aluminum Soffit | Fast, secure hold, hidden in the groove, cost-effective. | Requires a specific staple gun, potential for over-driving without depth control. |

| Aluminum Soffit Nails | Aluminum & Wood Soffit | Corrosion-resistant, good holding power. | Slow to install by hand, can bend easily, risk of hammer marks on the soffit. |

| Stainless Steel Screws | All Soffit Types (Coastal Areas) | Maximum corrosion resistance, very strong hold. | Very slow installation, can easily crack vinyl if over-tightened. |

| Roofing Nails | Not Recommended | Widely available. | Head is too large, will damage vinyl/aluminum, not corrosion-resistant, unprofessional finish. |

Troubleshooting Common Soffit Stapling Issues

Even with the right tools and techniques, you might encounter some issues during your soffit installation. Understanding how to quickly diagnose and solve these common problems will keep your project on track and ensure a professional-quality result.

Problem: Staples are blasting through the soffit (Over-driving). This is the most frequent and damaging issue, especially with delicate vinyl. The solution is to decrease the air pressure on your compressor and/or adjust the depth-of-drive setting on your stapler. You want the staple crown to sit flush with the surface of the nailing hem, not break through it.

Problem: Staples aren’t sinking deep enough (Under-driving). If the staples are left sticking out, they won’t hold the panel securely and will interfere with the next piece. First, try increasing the air pressure slightly. If that doesn’t work, check if your pneumatic tool needs a few drops of oil. An under-lubricated tool can lose power.

Problem: The staple gun is jamming frequently. Jams can be caused by a few things. Ensure you are using the correct size and collation type of staples recommended by the manufacturer. Also, holding the tool firmly and flush against the work surface prevents the gun from recoiling, which can cause a staple to misfire and jam.

Beyond the Basics: Maintenance and Advanced Tips

Taking your soffit installation from good to great involves a few advanced techniques and a commitment to proper tool maintenance. These pro tips will help you achieve a truly flawless finish and extend the life of your equipment.

A simple but effective trick for perfectly straight installations is to snap a chalk line on the framing where the edge of your soffit panels will be fastened. This gives you a clear guide to follow, ensuring your staples are aligned and the panels are straight. When working with vinyl, remember to leave a slight gap (about 1/4 inch) at the ends to allow for natural expansion and contraction with temperature changes. Fastening it too tightly can cause it to buckle or warp.

Proper tool care is also essential. For pneumatic staplers, this means adding a few drops of air tool oil into the air inlet at the beginning of each day. This lubricates the internal components and ensures consistent performance. After use, wipe down the tool and store it in a clean, dry place to prevent rust and damage.

The Final Word: Elevate Your Soffit Game

Successfully installing soffit is a rewarding project that significantly improves your home’s appearance and protection. The key takeaway is that shortcuts lead to failure. Sagging, loose panels are not just an eyesore but a sign of improper technique and, most importantly, the wrong tools.

By investing in a quality narrow crown staple gun, using the correct corrosion-resistant staples, and mastering the techniques of proper depth control and placement, you can overcome common frustrations. You’ll transform a challenging task into a fast, efficient, and professional-grade installation. Your reward will be a clean, durable finish that you can be proud of for years to come.

Exterior work often involves more than one task. If you’re planning a larger renovation, you might find that knowing how to buy paint for your trim and siding is a helpful next step. When budgeting for larger projects, understanding related costs, such as how much do painters charge to move furniture, can provide a more complete financial picture.

Frequently Asked Questions (FAQ)

Can I use a regular T50 stapler for soffit?

No, you should not use a standard T50 or manual craft stapler for soffit installation. These tools lack the power to drive staples deep enough into the wood framing for a secure hold. Furthermore, the staples they use are too thin and do not have the required holding power, which will lead to sagging and failure over time.

What is the best size staple for vinyl soffit?

The industry standard and best choice is an 18-gauge, 1/4-inch narrow crown staple. The length should be between 1 inch and 1 1/4 inches to ensure adequate penetration into the underlying wood structure. Always opt for galvanized or stainless steel staples to prevent rust.

Is it better to use a staple gun or a nail gun for soffit?

A staple gun is superior for installing vinyl and aluminum soffit. The two legs of a staple provide a much wider and more secure hold on the thin material compared to a single brad nail. This significantly reduces the risk of the panel tearing or pulling away from the fastener in high winds.

How far apart should soffit staples be spaced?

You should place one staple into a solid framing member (like a rafter tail or sub-fascia) every 12 to 16 inches. Consistent spacing is key to preventing sagging and ensuring the entire length of the panel is securely supported.

Do I need to use stainless steel staples?

While galvanized staples are sufficient for many environments, using stainless steel staples is highly recommended if you live in a coastal area, a region with high humidity, or anywhere salt is used on roads in winter. Stainless steel offers the ultimate protection against corrosion and will prevent rust streaks from staining your soffit.

Once your project is complete, a thorough cleanup is the final step. If you’ve dealt with any sealants or compounds during your repairs, knowing how to clean pipe dope and other residues can be incredibly useful for getting your tools and work area spotless.