Snowblower Running Rich? Stop Black Smoke & Fuel Waste NOW

There’s nothing more frustrating than a snowblower that sputters, coughs out black smoke, and burns through fuel at an alarming rate. When your machine is running rich, it means the delicate balance of air and fuel required for combustion is off. Instead of an efficient engine, you have a fuel-guzzling, poorly performing machine that’s actively damaging itself.

Understanding the signs of a rich-running engine is the first step toward a solution. Telltale symptoms include visible black smoke from the exhaust, a strong smell of gasoline, and spark plugs that are consistently fouled with black, sooty deposits. Ignoring these signs not only wastes expensive fuel but can lead to long-term engine damage.

You'll Learn About

Why Your Snowblower Is Running Rich: The Core Causes

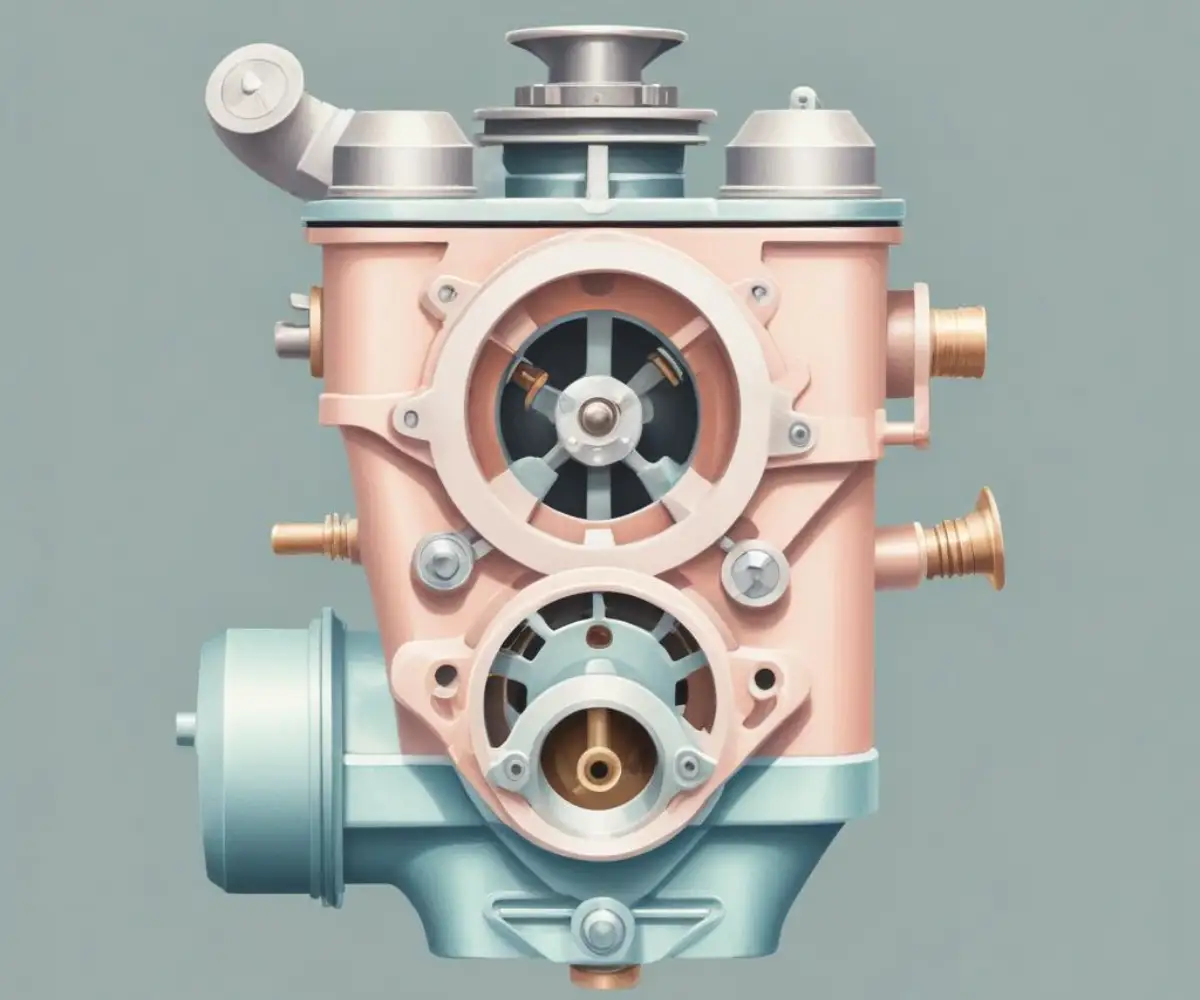

A snowblower engine runs rich when the carburetor delivers too much fuel and not enough air into the combustion chamber. This imbalance can be traced back to a few key culprits. Each component plays a critical role in maintaining the precise air-fuel ratio needed for optimal performance.

From simple maintenance oversights to more complex carburetor issues, identifying the root cause is essential. Addressing these problems will restore your snowblower’s power, improve its fuel efficiency, and prevent more serious repairs down the road.

The Choke is Stuck or Misadjusted

The choke’s job is to restrict airflow, creating a fuel-heavy mixture to help a cold engine start. However, if the choke plate remains partially or fully closed after the engine has warmed up, it will continuously starve the engine of air, causing it to run rich. This can happen due to a seized cable, a misaligned lever, or internal grime preventing the choke plate from opening fully.

Your Air Filter is Clogged

While many snowblowers don’t have traditional air filters to prevent icing, those that do can suffer greatly from a clogged one. A dirty air filter physically blocks air from entering the carburetor. The carburetor, unaware of the air restriction, continues to supply the standard amount of fuel, creating a rich mixture. This is one of the most common and easily fixed causes of a rich-running engine.

A restricted air supply forces the engine to work harder, consume more fuel, and ultimately leads to poor performance and black smoke. Regular inspection and replacement of the air filter is a simple yet vital maintenance task.

Carburetor Malfunctions are the Prime Suspect

The carburetor is the heart of your snowblower’s fuel system, and it’s often the primary source of rich-running issues. Several internal components can fail or become misadjusted, leading to an excessive flow of fuel. These problems can range from simple adjustments to needing a full cleaning or rebuild.

Problems within the carburetor, such as a stuck float, a worn needle valve, or improperly set adjustment screws, directly impact the air-fuel mixture. Even small amounts of debris or varnish from old fuel can cause these sensitive parts to malfunction.

The Damaging Effects of Modern Fuel

Today’s gasoline, particularly fuel containing ethanol (like E10), can wreak havoc on small engines. Ethanol is corrosive and absorbs water, which can lead to rust and deterioration of rubber and plastic components inside the carburetor. This degradation can cause parts like the needle valve tip to fail, allowing fuel to continuously flood the carburetor bowl.

Furthermore, ethanol acts as a solvent, breaking down old varnish deposits in the fuel tank and lines. These dislodged particles can then travel to the carburetor and clog tiny passages and jets, disrupting the precise flow of fuel and contributing to a rich condition.

Step-by-Step Guide to Fixing a Rich-Running Snowblower

Now that you understand the causes, it’s time to take action. This guide provides a systematic approach to diagnosing and fixing the problem, starting with the simplest solutions first. Following these steps will help you restore your snowblower’s performance efficiently.

1. Inspect and Service the Choke System

Your first check should be the choke mechanism. With the engine off, move the choke lever from the open to the closed position. Watch the choke plate inside the carburetor’s throat to ensure it moves freely and fully in both directions.

If it sticks, lubricate the linkage and pivot points. If the cable is stiff or broken, it will need to be replaced. Ensuring the choke opens completely is a critical first step in leaning out the fuel mixture.

2. Clean or Replace the Air Filter

If your snowblower is equipped with an air filter, inspect it immediately. Remove the filter cover and take out the filter. A paper filter that is visibly dirty or oily should be replaced. A foam filter can often be washed with soap and water, thoroughly dried, and then lightly re-oiled before reinstallation.

3. Adjust the Carburetor Screws

Many carburetors have adjustment screws that control the fuel mixture at idle and high speeds. These are typically a main jet screw (often on the bottom of the fuel bowl) and an idle mixture screw (on the side of the carburetor body). The goal is to find the “sweet spot” where the engine runs smoothly without sputtering (too lean) or chugging (too rich).

Start the engine and let it warm up for several minutes. With the engine at full throttle, slowly turn the main jet screw clockwise until the engine begins to stumble. Then, turn it counter-clockwise until it starts to run rough again. The optimal setting is halfway between these two points.

Next, reduce the engine to idle speed and repeat the process with the idle mixture screw. Fine-tuning these screws is crucial for engine performance. If you notice a strong gasoline odor while working, it’s a strong sign your adjustments are needed.

4. Perform a Thorough Carburetor Cleaning

If adjustments don’t solve the problem, a full carburetor cleaning is necessary. Stale fuel can leave behind a sticky residue that clogs the tiny passages, known as jets, inside the carburetor. This requires removing the carburetor from the engine for a complete disassembly and cleaning.

Carefully disassemble the unit, paying close attention to the float, needle valve, main jet, and idle jet. Use a dedicated carburetor cleaner spray to dissolve all varnish and grime. Ensure every jet and passage is clear by passing a very fine wire or micro drill bit through them before reassembly. This process is often essential for equipment like a John Deere 826 Snowblower that has been sitting for a season.

5. Check the Float and Needle Valve

A critical component inside the carburetor is the float and needle valve assembly, which regulates the amount of fuel in the carburetor bowl. If the float is saturated and no longer buoyant, or if the rubber tip on the needle is worn, it won’t properly shut off the fuel supply from the tank. This leads to a constantly overflowing bowl and an extremely rich condition.

During your carburetor cleaning, inspect these parts carefully. A brass float can be tested for leaks by submerging it in liquid. If you see bubbles, it needs to be replaced. Ensure the needle valve moves freely and its tip creates a perfect seal.

Understanding Rich vs. Lean Conditions

Diagnosing engine problems accurately requires knowing the difference between running rich and running lean. A lean condition, the opposite of rich, means there is too much air and not enough fuel. The table below outlines the key symptoms to help you distinguish between the two.

| Symptom | Running Rich (Too Much Fuel) | Running Lean (Too Little Fuel) |

|---|---|---|

| Exhaust Smoke | Black, sooty smoke | No visible smoke, may run hotter |

| Engine Performance | Sluggish, bogging down, low power | Surging, hunting for RPM, backfiring |

| Spark Plug Condition | Black, dry, and sooty | White, blistered, or chalky |

| Smell | Strong smell of raw gasoline | No distinct smell, possibly hot metal smell |

| Starting | May be hard to start when warm | Difficult to start when cold, requires lots of choke |

Preventative Maintenance is Your Best Defense

The best way to deal with a rich-running snowblower is to prevent it from happening in the first place. Consistent, simple maintenance can save you hours of frustration and costly repairs. Following a few key practices will keep your machine running reliably all winter long.

Small engines, like those in a Simplicity 555 Snowblower, are particularly sensitive to fuel quality and storage. Proper care at the end of the season is just as important as pre-season preparation.

Use High-Quality, Fresh Fuel

Always use fresh gasoline (less than 30 days old) with the lowest possible ethanol content. If available, ethanol-free gasoline is the best choice for small engines as it eliminates the risk of moisture absorption and component corrosion. Using a fuel stabilizer is also essential, especially if the fuel will sit for more than a month.

A good stabilizer prevents fuel from degrading and forming the gummy deposits that clog carburetors. This simple additive can prevent the most common cause of fuel system problems.

Proper End-of-Season Storage

At the end of the winter season, proper storage is crucial. Either drain the fuel system completely—including the tank, fuel lines, and carburetor bowl—or fill the tank with fresh, stabilizer-treated fuel and run the engine for several minutes. Running the engine circulates the treated fuel through the entire system, protecting it during the off-season.

Draining the system is often the safest bet to prevent any fuel-related issues. An empty carburetor cannot get clogged with varnish, ensuring a much easier start when the first snow falls next season.