Snowblower Not Throwing Far? The Ultimate Rubber Flap Mod Guide

There’s nothing more frustrating than a snowblower that can’t keep up. You’re out in the freezing cold, bundled up against the wind, and your machine just isn’t performing. Instead of a powerful stream of snow arcing gracefully into your yard, you get a weak, short plume that barely clears the machine, or worse, a frustrating clog of heavy, wet snow that brings the whole operation to a standstill.

This common problem plagues many snowblower owners, especially when dealing with the heavy, slushy snow left by city plows at the end of the driveway. It forces you to work slower, make multiple passes, and constantly stop to clear the discharge chute. This not only wastes your time but also puts unnecessary strain on your snowblower’s engine and your back.

You'll Learn About

Understanding the Core Problem: The Impeller Gap

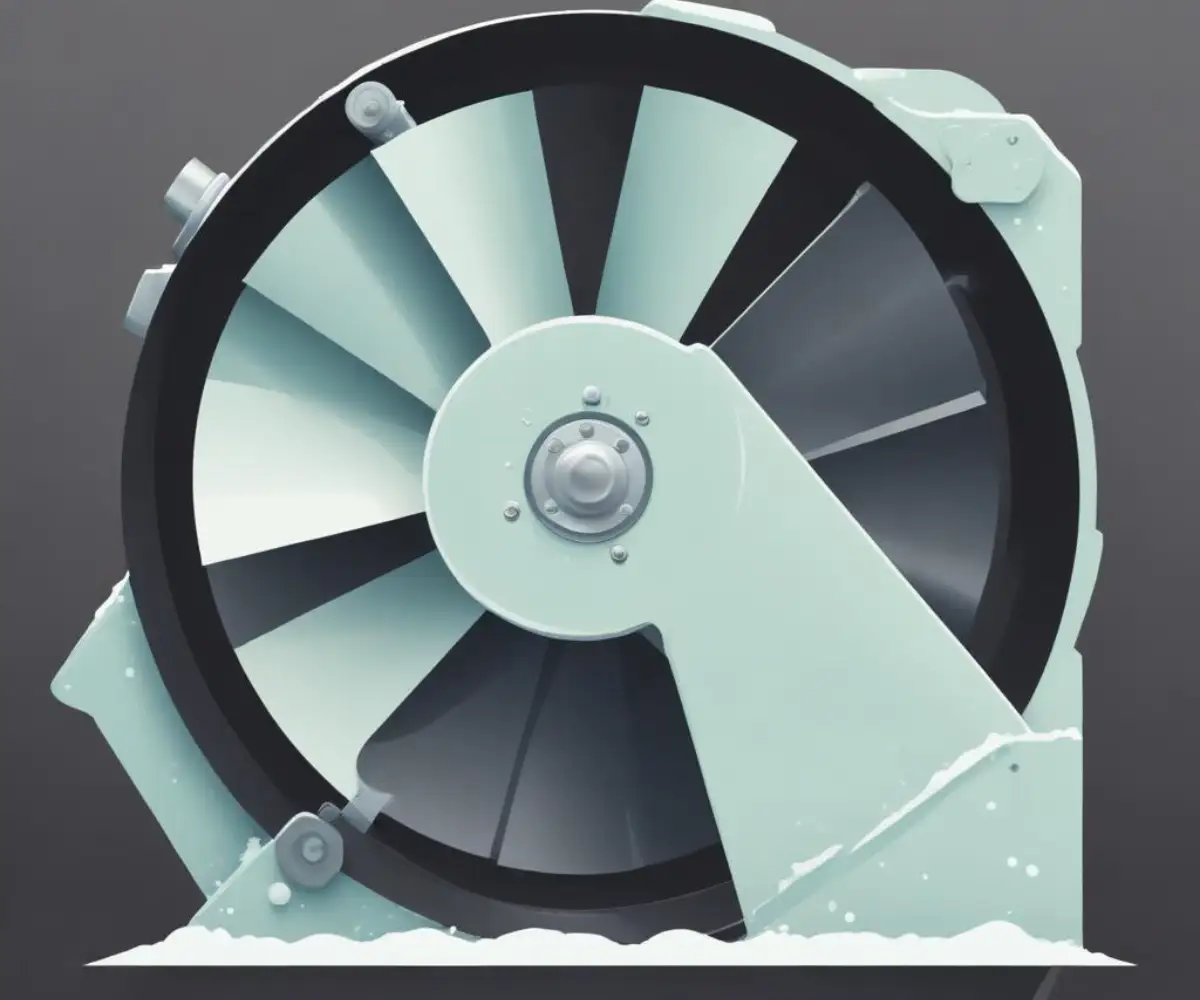

The root cause of this poor performance in most two-stage and three-stage snowblowers is a simple design compromise: the gap between the impeller blades and the impeller housing. The impeller is the high-speed fan, hidden behind the main augers, that’s responsible for grabbing the snow and launching it out of the chute. To prevent the fast-spinning metal blades from striking the metal housing, manufacturers intentionally leave a space, which can be anywhere from a quarter-inch to over half an inch wide.

While this gap prevents damage, it creates a major inefficiency. As the impeller spins, a significant amount of snow, especially the wet and heavy kind, slips through this gap. This “blow-by” means the impeller can’t build up enough pressure to throw the snow effectively, leading to weak throwing distances and frequent clogs as snow builds up inside the housing instead of being ejected. The machine loses velocity and power, turning a powerful storm-clearing tool into a source of winter frustration.

The Solution: The High-Performance Rubber Flap Modification

The single most effective and affordable upgrade to solve this problem is the snowblower rubber flap mod, often called the impeller mod. This modification involves attaching a durable piece of rubber to each impeller blade, effectively closing that inefficient gap. The rubber flap acts like a squeegee, wiping the inside of the impeller housing clean with every rotation.

This simple addition creates a tight seal that prevents snow from escaping past the blades. The result is a dramatic increase in the machine’s efficiency. All the power from the engine is now channeled directly into propelling the snow, leading to significantly farther throwing distances and the virtual elimination of clogs, even in the slushiest conditions. Many users report a doubling of their throwing distance and the ability to power through heavy snow that would have instantly clogged their machine before.

Is This Mod Right for My Snowblower?

It’s important to note that this modification is designed specifically for two-stage and three-stage snowblowers. These models have a separate auger for gathering snow and an impeller for throwing it. Single-stage snowblowers operate on a different principle, using rubber auger paddles that make direct contact with the ground to both gather and throw the snow, so this modification does not apply to them.

Getting Started: DIY Mod vs. Pre-Made Impeller Kits

Before you begin, you have a choice to make: create your own flaps from scratch (DIY) or purchase a pre-made kit. Both options are effective, and the best choice depends on your budget, time, and comfort level with fabrication.

A DIY approach is the most cost-effective. You can source durable rubber from various places, such as old truck mud flaps, agricultural baler belting, or reinforced conveyor belts. This gives you full control over the material and size. A pre-made kit, on the other hand, offers convenience. These kits typically include pre-cut rubber flaps, mounting hardware, and sometimes even metal backing plates for added rigidity, taking the guesswork out of the equation.

| Component | DIY Material Suggestions | Kit Component (Typical) | Key Considerations |

|---|---|---|---|

| Flap Material | Reinforced Rubber (Truck Mud Flap, Conveyor/Baler Belt), SBR Rubber Sheet | Pre-cut SBR Rubber Paddles | Thickness of 1/4″ to 3/8″ is ideal. Material must be durable and resistant to cold. |

| Fasteners | 5/16″ Bolts, Nylon Lock Nuts, and Washers | (3-4x) Bolts and Lock Nuts per blade | Stainless steel hardware is strongly recommended to prevent rust and corrosion. |

| Backing Plate | 1/8″ Thick Steel or Aluminum Flat Bar | (Optional) Pre-drilled steel straps | Adds rigidity and prevents the rubber from flexing under heavy load. Recommended but not essential. |

| Tools | Drill, Step Bit, Wrenches, Socket Set, Marker, Utility Knife, C-clamps | Requires standard hand tools | A step drill bit is highly effective for drilling clean holes in the metal impeller blades. |

The Ultimate Step-by-Step Guide to the Rubber Flap Mod

Installing the rubber flap mod is a straightforward process that can be completed in about one to two hours with basic tools. Following these steps will ensure a safe and effective installation, transforming your snowblower’s performance.

Step 1: Safety is Paramount

Before beginning any work, your first and most important step is to ensure the snowblower cannot start accidentally. Disconnect the spark plug wire and secure it away from the spark plug. For electric-start models, also ensure the key is removed and the power cord is unplugged. This prevents any possibility of the engine turning over while your hands are inside the auger and impeller housing.

Step 2: Access the Impeller

To get to the impeller, you will need to remove the discharge chute. This is typically held in place by three to five bolts at its base. Once the bolts are removed, the entire chute assembly can be lifted off, giving you a clear view and direct access down into the impeller housing. Take a moment to clean out any old snow or debris from the area.

Step 3: Create a Precise Template

A perfect fit is key to the success of this mod. The easiest way to achieve this is by creating a template from a piece of cardboard. Cut a piece of cardboard that is roughly the size of one of the impeller blades. Place it against the blade and trace the shape of the impeller housing’s curve onto the cardboard. The goal is to create a shape that perfectly fills the gap from the metal blade to the housing wall.

Step 4: Cut Your Rubber Flaps

Once you are satisfied with your cardboard template, trace its shape onto your rubber material. You will need one flap for each impeller blade (most machines have three or four). Use a sharp utility knife to carefully cut out the rubber flaps. For thicker rubber, you may need to make several passes. Ensure all flaps are cut to the identical size and shape; this is crucial for maintaining the balance of the spinning impeller.

Step 5: Drill and Mount the Flaps

Position a rubber flap on the leading edge of an impeller blade—the side that pushes the snow. You want the flap to be flush against the housing wall or leave a tiny gap of about 1/16 of an inch. The rubber will wear down slightly to create a perfect custom fit after a few minutes of use. Clamp the flap securely to the blade.

Using your drill and a bit sized for your bolts (a 3/8″ step bit works well for 5/16″ bolts), drill two holes through both the rubber and the metal impeller blade. To prevent the impeller from spinning while you drill, you can wedge a block of wood into the housing. Skipping this safety measure is like ignoring a warning light on your dashboard; it could lead to significant problems later.

Here is an expert technique to ensure maximum performance and durability: before bolting, apply a thin layer of a strong, cold-weather resistant epoxy like J-B Weld to the surface of the impeller blade where the rubber will sit. This creates an incredibly strong bond that prevents the flap from flexing backward under the force of heavy slush, maintaining a rigid profile and maximizing throwing power. It also dampens vibration and seals the connection point.

Insert your bolts from the back of the impeller blade, through the metal and the rubber. If you are using a metal backing plate, place it over the bolts on top of the rubber. Secure everything tightly with washers and nylon lock nuts. Repeat this process for all remaining impeller blades.

Step 6: Final Checks and Reassembly

Before reinstalling the chute, manually and slowly rotate the impeller by hand for several full rotations. Feel for any points where the flaps might be binding or scraping excessively against the housing. A light, smooth sweeping contact is ideal. If there is significant resistance, you may need to trim the rubber slightly. Ensuring the perfect fit is critical; a flap that doesn’t fit correctly can cause poor performance or engine strain.

Once you’ve confirmed the clearance is correct, reinstall the chute assembly, tightening all bolts securely. Reconnect the spark plug wire, and your snowblower is now ready for a test run. You may notice a slight burning rubber smell during the first few minutes of operation; this is normal as the flaps wear in to form a perfect seal with the housing.

The Incredible Benefits: What to Expect After the Mod

Completing the rubber flap modification will feel like you’ve upgraded to a brand-new, more powerful machine. The improvements are immediate and significant.

Dramatically Increased Throwing Distance

The most noticeable benefit is the astonishing increase in throwing distance. By creating an efficient seal, the impeller can now use the engine’s full power to launch snow. It’s common for users to see their throwing distance increase by 50% to 100% or even more. Snow that once barely cleared the machine will now be thrown dozens of feet away.

Elimination of Clogs with Wet, Heavy Snow

This modification truly shines when dealing with the heavy, wet snow at the end of the driveway. The rubber flaps act as a squeegee, constantly clearing the housing and preventing slush from building up. The powerful, continuous flow of snow keeps the chute clear, virtually eliminating the clogs that used to bring your work to a halt.

Faster and More Efficient Snow Clearing

With increased throwing distance and no time wasted clearing clogs, you’ll be able to clear your driveway much faster. You can take fuller passes through deeper snow without the engine bogging down. This efficiency makes the entire job less of a chore and gets you back inside where it’s warm much quicker.

Potential Risks and How to Mitigate Them

While the rubber flap mod is overwhelmingly successful, it’s important to be aware of a few potential issues, all of which can be avoided with proper installation.

Impeller Imbalance: If the rubber flaps are not cut to a uniform size and weight, it can create an imbalance in the high-speed impeller, leading to vibration and potential long-term wear on the bearings. Solution: Use a template and carefully cut each flap to be as identical as possible.

Engine Strain: If the rubber flaps are too long and create excessive friction against the housing, it can put an extra load on the engine and drive belts. Solution: Ensure a minimal clearance (around 1/16″) during installation. The rubber’s flexibility is key; it’s designed to flex and wear, unlike rigid materials. This is related to how different materials handle force, much like how some tiles feel colder than others due to differences in thermal conductivity.

Is the Snowblower Rubber Flap Mod Worth It?

For any owner of a two-stage snowblower who has struggled with poor throwing distance or constant clogging, the answer is a resounding yes. This modification is arguably the single most cost-effective, high-impact upgrade you can perform. For a minimal investment in materials and a couple of hours of your time, you can dramatically improve your machine’s performance, making it more powerful and reliable than ever before.

By closing the factory-designed efficiency gap, you unlock the true potential of your snowblower. You’ll be able to tackle the deepest, wettest snow with confidence, clearing your driveway faster and more effectively, and turning a frustrating winter chore into a satisfying display of power and efficiency.