Snowblower Gearbox Oil: The Secret Weapon for a Long-Lasting Machine

That powerful snowblower sitting in your garage is a winter workhorse, but deep inside its metal heart lies a component most owners forget: the auger gearbox. This small, sealed unit is responsible for transferring immense power from the engine to the augers that chew through heavy snow. Yet, it’s often the most neglected part, leading to catastrophic—and expensive—failures that could have been easily avoided.

The single biggest mistake is assuming the lubricant inside will last forever. Over time, that oil or grease breaks down, loses its protective qualities, and can lead to stripped gears and a seized machine right when you need it most. Understanding and properly maintaining your gearbox oil is the key to ensuring your snowblower survives season after season of harsh use.

You'll Learn About

Why Your Snowblower’s Gearbox is the Unsung Hero of Winter

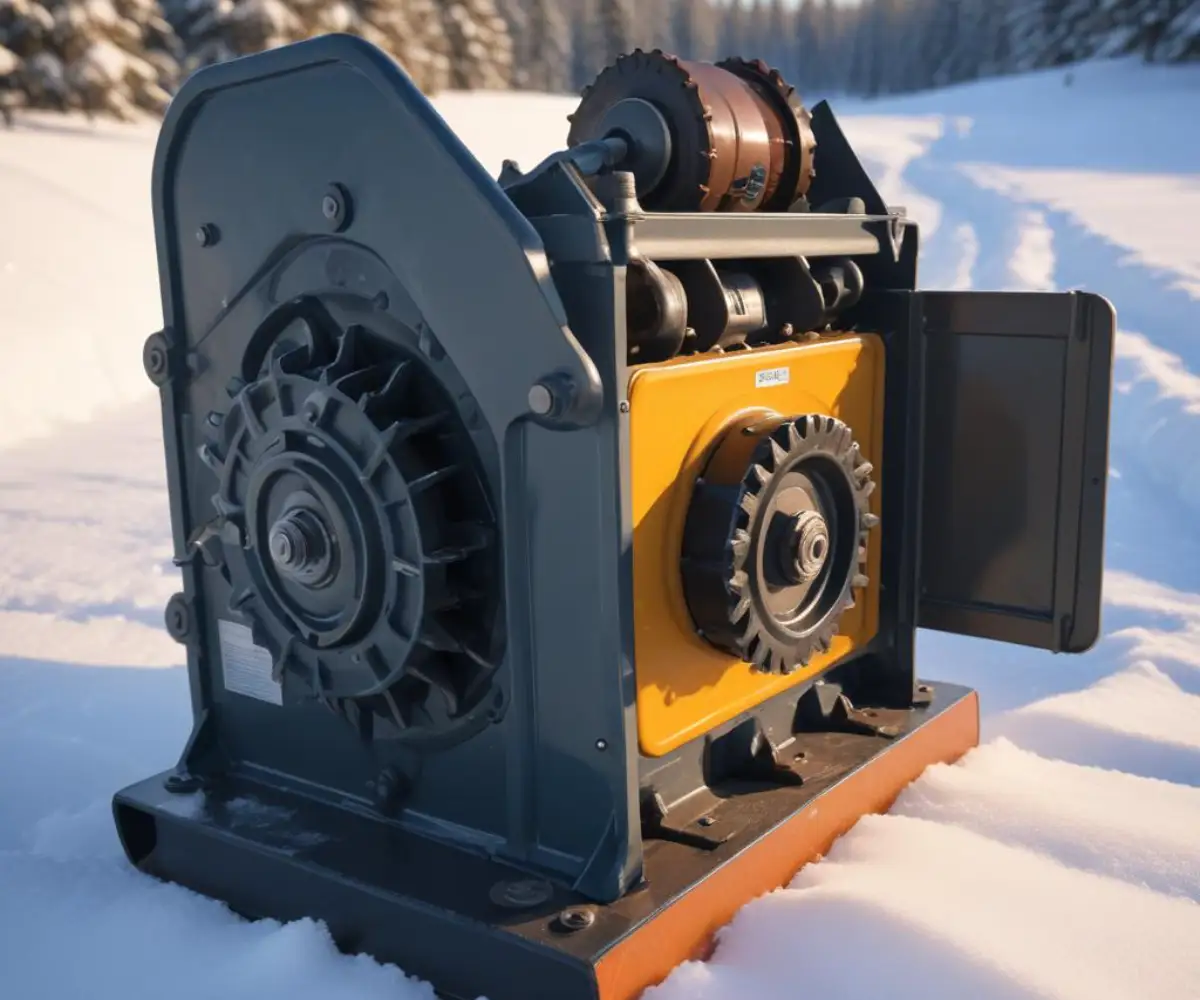

Think of the auger gearbox as the transmission for the front end of your machine. It takes the high-speed rotational force from the engine’s drive belt and converts it into the low-speed, high-torque power needed to turn the augers. This process generates incredible pressure and friction between the internal gears, typically a steel worm gear driving a softer bronze or brass gear.

This little box operates in the worst possible conditions: extreme cold, constant moisture, and immense strain from heavy, wet snow or chunks of ice. The lubricant inside is the only thing standing between these precision-machined gears and rapid destruction. Without proper lubrication, the metal-on-metal contact would quickly lead to overheating, wear, and ultimately, a dead snowblower.

The #1 Mistake Owners Make with Gearbox Oil (and How to Avoid It)

The most common and costly mistake is neglect. Many owner’s manuals are surprisingly vague about gearbox maintenance, sometimes calling the lubricant “permanent” or providing no service interval at all. This leads owners to believe it never needs attention, which is a recipe for disaster.

Over time, the oil inside becomes contaminated with microscopic metal particles from normal gear wear. Moisture can also find its way in, causing the oil to emulsify and lose its ability to lubricate effectively. This degraded fluid can no longer provide the protective film necessary, leading to stripped gears and a silent, motionless auger in the middle of a blizzard.

Decoding Gearbox Oil: Synthetic vs. Conventional and Why It Matters

Choosing the right lubricant is critical, especially given the cold temperatures a snowblower operates in. The two primary choices are conventional mineral oil and full synthetic oil, and for this application, synthetic is the undisputed champion.

Synthetic gear oil is engineered to perform exceptionally well in extreme cold. It maintains its viscosity and flows freely, ensuring the gears are lubricated from the moment you start the engine. Conventional oil, on the other hand, can become as thick as honey in freezing temperatures, leading to a “dry start” that causes significant wear until the gearbox warms up.

Understanding Viscosity and Additives

You’ll see numbers like 80W-90 or 75W-140 on gear oil bottles. The “W” stands for “Winter,” and the number preceding it indicates its flow characteristics at low temperatures—a lower number means it flows better when cold. For snowblowers, a 75W or 80W synthetic oil is an excellent choice.

Additionally, look for oils with an “EP” (Extreme Pressure) rating. These oils contain special additives that bond to the metal surfaces of the gears, providing a crucial layer of protection against the immense forces generated inside the gearbox. This prevents the metal surfaces from grinding against each other under heavy loads.

Choosing the Right Snowblower Gearbox Oil: A Brand-by-Brand Guide

While many gearboxes use similar lubricants, manufacturers often have specific recommendations. Using the wrong type of oil can sometimes cause issues. For example, some older gearboxes use brass or bronze gears, and certain EP additives in GL-5 rated oils can be corrosive to these “yellow metals.” When in doubt, a high-quality synthetic 80W-90 GL-4 or a manufacturer-specified fluid is a safe bet.

Many owners wonder about finding an equivalent for a specific brand’s gear lube, like the popular Ariens L3. While manufacturer oils are always a good choice, other high-quality synthetic gear oils with similar specifications will perform just as well. The key is to match the viscosity and ensure it’s safe for any yellow metals in the gearbox.

| Brand | Recommended Gear Oil / Lube | Common Models | Notes |

|---|---|---|---|

| Ariens | Ariens L3 Synthetic Gear Lube (or equivalent 75W-90/80W-90 Synthetic) | Deluxe, Platinum, Professional Series | L3 is a high-quality synthetic fluid. A suitable synthetic gear oil is a great alternative if L3 is unavailable. |

| Toro | SAE 80W-90 EP Gear Oil (GL-5) | Power Max, Power Clear | Toro manuals often specify a conventional GL-5 gear oil. Always check your specific manual. |

| Craftsman / MTD / Cub Cadet | Often “00” Grease or 80W-90 Gear Oil | Various 2-stage and 3-stage models | These brands have used both grease and oil. If a unit leaks oil, some owners switch to “00” grease, which is semi-fluid and less likely to leak. |

| Husqvarna | Often “Lubed for Life” (uses grease) | ST Series | Many models are factory-filled with grease. Service may require disassembly to repack the gearbox. |

The Step-by-Step Guide to Changing Your Snowblower’s Gearbox Oil

Changing the gearbox oil is a straightforward task that requires only basic tools. Performing this service every two seasons can dramatically extend the life of your machine.

Step 1: Gather Your Supplies

You will need a wrench to fit the drain and fill plugs, a drain pan, fresh gear oil, rags, and potentially some thread sealant for the plugs.

Step 2: Warm Up the Machine (A Pro Tip)

Run the snowblower for about 5-10 minutes before draining. This warms the oil, making it less viscous and allowing it to drain more completely, carrying more contaminants with it.

Step 3: Locate and Access the Gearbox

The gearbox is located on the front of the snowblower, between the augers. You will typically find a fill plug on the top or side and a drain plug on the bottom.

Step 4: Drain the Old Oil

Place your drain pan underneath the drain plug. Carefully remove the plug and let the old oil drain completely. Inspect the old oil for a milky appearance (indicating water) or shiny metal flakes (a sign of severe gear wear).

Step 5: Refill with New Oil

Replace the drain plug. Slowly add the new gear oil through the fill hole until it reaches the bottom of the threads of the fill hole or a specified level indicated in your manual. Do not overfill, as this can build excess pressure and blow out seals.

Step 6: Seal and Reassemble

Apply a small amount of thread sealant to the fill plug threads and tighten it securely. Wipe away any spilled oil, and you are done.

How Often Should You *Really* Change the Gearbox Oil?

Forget the “lubed for life” myth. For optimal protection, a proactive approach is best. A good rule of thumb is to change the gearbox oil every 25-50 hours of operation or at least once every two winter seasons, whichever comes first.

If you live in an area with heavy, wet snow, your machine works much harder, and an annual change is cheap insurance against a costly repair. This simple task is far more important than many other maintenance items for ensuring long-term reliability.

Recognizing the Warning Signs of Gearbox Trouble

A failing gearbox will usually give you warning signs. Paying attention to them can help you catch a problem before it becomes a complete failure.

- Grinding or Whining Noises: Any unusual noises coming from the front of the machine during auger operation could signal worn gears or bearings.

- Leaking Fluid: If you notice your snowblower is leaking a yellow or dark fluid from the auger area, the gearbox seals are likely failing.

- Jerky or Hesitant Auger Rotation: If the augers struggle to turn or move inconsistently, it could be a sign of damaged gear teeth.

In severe cases, a failing gearbox can put stress on other components. The intense vibration from stripped gears could even contribute to issues that look like you have a bent snowblower housing. Eventually, a seized gearbox can even cause the snowblower’s wheels to lock up if the failure is catastrophic enough to jam the drive system.

What About “Lubed for Life” Gearboxes? The Hard Truth

Many modern snowblowers are sold with gearboxes that are “lubricated for life.” This is often a marketing term that means the lubricant is designed to last through the warranty period, not the actual lifespan of the machine. These units are typically filled with a heavy grease instead of oil and may not have a drain plug.

Even on these models, the grease can dry out or become contaminated over many years of use. While servicing them is more involved—requiring splitting the gearbox case to clean and repack it—it’s a task that can prevent premature failure and keep an older machine running strong.

The Hidden Dangers of Using the Wrong Oil

Using an incorrect lubricant can be just as damaging as using none at all. The most critical aspect for many snowblowers is ensuring the oil is “yellow metal safe.” Many gearboxes use a large bronze or brass worm gear, which is softer than the steel drive gear it meshes with.

Some automotive gear oils, particularly those with a GL-5 rating, contain sulfur-phosphorus additives that can be corrosive to these softer yellow metals over time. This corrosion can weaken the gear and lead to premature stripping. Always check that the gear oil you choose is specified as safe for bronze or yellow metals if your gearbox contains them.

Conclusion: A Small Task for a Huge Reward

Your snowblower’s gearbox is a tough, hardworking component that deserves more attention than it gets. A few dollars spent on a bottle of high-quality synthetic gear oil and thirty minutes of your time every couple of seasons is one of the smartest investments you can make.

By ensuring your gearbox is filled with clean, effective lubricant, you are directly protecting the most critical—and one of the most expensive—parts of your machine. This simple act of preventative maintenance will reward you with reliable performance, a longer machine life, and peace of mind during the harshest winter storms.