Stuck Snow Blower Shear Pin? Your Ultimate 5-Step Rescue Guide

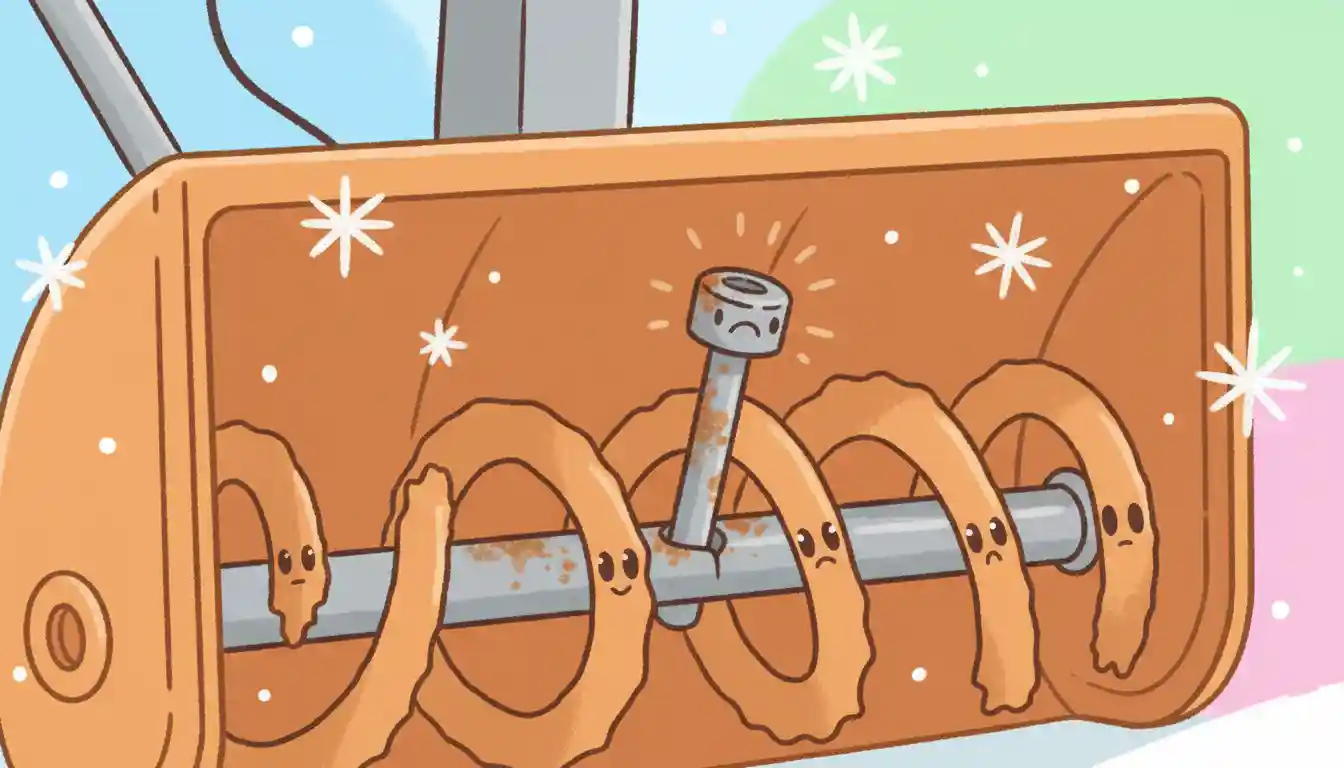

There’s nothing more frustrating than being ready to clear a heavy snowfall only to find your snow blower’s augers won’t turn. You check the engine, the belts, but the problem is often a tiny, overlooked part: a broken or stuck shear pin. This small component is the unsung hero of your machine, and when it’s seized, your powerful snow blower becomes nothing more than a heavy garage ornament.

A stuck shear pin can halt your snow clearing operations instantly, leaving you with a frustrating and difficult repair. But don’t despair. This guide provides a comprehensive, step-by-step approach to safely remove even the most stubborn shear pin and get your machine back to peak performance.

You'll Learn About

What Exactly Is a Shear Pin & Why Does It Matter?

Think of a shear pin, sometimes called a shear bolt, as a mechanical fuse for your snow blower. Its single, crucial job is to be the weakest link in the auger drive system. It connects the auger blades to the rotating auger shaft, allowing them to spin and chew through snow.

When your auger hits a solid object like a rock, a thick branch, or a frozen newspaper, the force would normally travel straight to the expensive gearbox, causing catastrophic damage. Instead, the shear pin is designed to break under a specific amount of force, instantly disconnecting the auger from the shaft and protecting the delicate internal gears from destruction. A broken pin is a small inconvenience; a destroyed gearbox is a major, costly repair.

The Real Reasons Your Shear Pin Is Stuck Solid

Understanding why a pin gets stuck is the first step toward preventing it from happening again. It’s rarely a single cause, but often a combination of factors working against you.

Rust and Corrosion: The Silent Seizure

The most common enemy is rust. Snow blowers operate in wet, often salty environments. Moisture inevitably finds its way into the small gap between the steel shear pin and the auger shaft, leading to rust that effectively welds the two parts together.

This process creates a bond that can be stronger than the force of a hammer and punch, making removal incredibly difficult. Over time, this corrosion can make the pin impossible to remove without more aggressive measures.

Galvanic Corrosion: The Unseen Chemical Weld

A less-discussed but highly potent cause is galvanic corrosion. This happens when two different types of metal—like a steel shear pin and an aluminum auger shaft—are in contact in the presence of an electrolyte, which is simply water and road salt. An electrochemical reaction occurs, causing one metal to corrode much faster.

This process creates a powerful bond that is more than just rust. It’s a chemical seizure that requires significant force or specialized techniques to break, explaining why some pins feel immovably fused to the shaft.

Impact Damage and Deformation

When a shear pin does its job and breaks, the immense force can sometimes deform the pin’s remnant or slightly warp the hole in the auger shaft. The broken piece can become mushroomed or bent, creating a physical wedge that prevents it from being pushed out easily.

This is especially common if a standard bolt was incorrectly used as a replacement, as they are not designed to shear cleanly.

Using the Wrong Pin: A Costly Mistake

It can be tempting to grab a standard bolt from the hardware store, but this is a critical error. Never use a standard bolt as a shear pin. These bolts are made from hardened steel and are designed *not* to break, which completely defeats the purpose of this crucial safety feature. Using the wrong hardware will transfer destructive force directly to your gearbox.

Your Essential Toolkit: Prepare for the Extraction

Having the right tools on hand before you begin will make the process much smoother. Fighting with a stuck pin is hard enough without having to search for the right equipment mid-job. Gather these items first.

Basic Tools:

- A high-quality penetrating oil (products like PB Blaster, Liquid Wrench, or Kroil are superior to standard WD-40 for this task)

- A sturdy hammer

- A set of pin punches or a drift punch appropriately sized for the pin

- Safety glasses and gloves

- Locking pliers or vise-grips

- A wire brush for cleaning

Advanced Tools (for stubborn pins):

- A propane or MAP gas torch

- A power drill with a set of high-quality metal drill bits (cobalt is recommended)

- A center punch

- Screw extractor kit (as a last resort)

The Definitive Guide to Removing a Stuck Shear Pin

Approach this task with a tiered strategy, starting with the least aggressive method first. Only escalate to more forceful techniques if the previous step fails. Always disconnect the spark plug wire before working on the auger housing to prevent any chance of an accidental start-up.

Method 1: The First Assault – Penetrating Oil & Patience

Your first and best friend in this fight is a good penetrating oil. Don’t rush this step. Liberally spray the oil on both sides of the stuck shear pin, ensuring it seeps into the seam between the pin and the shaft.

Let the oil soak for at least 30 minutes to an hour, but several hours or even overnight is better for deeply rusted pins. Reapply the oil every so often. Sometimes, a few gentle taps with a hammer during this soaking period can help the oil penetrate deeper by breaking up the initial rust bond.

Method 2: Applying Force – The Punch and Hammer Technique

This is the most common and often successful method. First, ensure the auger shaft hole is aligned with the auger hole. You may need to wiggle the auger blade to get perfect alignment.

Select a pin punch that is slightly smaller than the diameter of the shear pin. Place the tip of the punch directly in the center of the pin and give it a few firm, sharp strikes with the hammer. Avoid light, rapid taps, which can peen or mushroom the end of the pin, making it harder to remove. A solid, forceful blow is more effective.

Method 3: When the Pin is Broken Flush – Drilling it Out

If the pin is broken off flush with the shaft or has mushroomed from previous attempts, drilling is your next best option. This method requires precision and patience to avoid damaging the auger shaft itself.

- Center Punch: Use a center punch to create a small indentation in the exact center of the broken pin. This will prevent your drill bit from “walking” off-center.

- Start Small: Begin with a small drill bit (e.g., 1/8 inch) and drill a pilot hole all the way through the pin. Use cutting oil to keep the bit cool and sharp.

- Increase Size Gradually: Move up to a slightly larger drill bit and widen the hole. Continue this process, increasing the bit size incrementally, until you are using a bit that is just slightly smaller than the pin’s original diameter.

- Collapse the Remnant: By drilling out the center, you have relieved the pressure and weakened the pin’s structure. Often, the remaining thin-walled shell of the pin will collapse. You can then use a punch to easily tap out the remaining fragments.

Method 4: The Technician’s Secret – Strategic Heat Application

For the most stubbornly seized pins, heat is a powerful ally. Metal expands when heated, and you can use this principle to your advantage. Exercise extreme caution with this method.

Using a propane or MAP torch, carefully apply heat to the auger shaft *around* the pin, not directly on the pin itself. The goal is to make the shaft expand slightly, breaking the corrosion bond holding the pin. Heat the area for 30-60 seconds, then attempt to drive the pin out with a punch and hammer. You may hear a distinct “pop” as the rust seal breaks. Never heat near fuel lines or the fuel tank, and be mindful of any plastic bushings in the area that could melt.

Method 5: The Final Option – Screw Extractors

If you have drilled a hole through the pin but it still won’t collapse, a screw extractor (like an “Easy Out”) can be used. These tools have reverse threads that bite into the inside of the drilled hole as you turn them counter-clockwise. As you turn the extractor, it will grip the inside of the pin and hopefully twist it free. This is a last-resort option, as extractors are brittle and can break off inside the pin if too much force is applied, creating an even bigger problem.

Choosing a Successor: The Critical Importance of OEM Pins

Once the old pin is out, the battle is only half won. Replacing it with the correct part is just as important as the removal. As mentioned, using a standard hardware store bolt is a recipe for disaster. Shear pins are made from a softer grade of metal specifically engineered to break at a precise torque limit to protect your gearbox.

A standard bolt is designed to be much stronger and will not shear. This means that instead of a $2 pin breaking, you risk a $300 gearbox failure. Always purchase Original Equipment Manufacturer (OEM) shear pins for your specific make and model. If you own a popular model, our guide to common repairs for an Ariens ST 524 can help you source the right parts.

| Feature | OEM Shear Pin | Standard Hardware Bolt |

|---|---|---|

| Material | Soft Steel (e.g., Grade 2) designed to break cleanly. | Hardened Steel (e.g., Grade 5 or 8) designed for high strength. |

| Primary Function | To act as a sacrificial link and protect the gearbox. | To be a strong fastener that resists breaking. |

| Failure Consequence | A quick, inexpensive pin replacement. | A potentially catastrophic and expensive gearbox failure. |

| Safety Rating | SAFE – Protects your investment as intended. | DANGEROUS – Bypasses a critical safety system. |

Future-Proofing Your Auger: Never Have a Stuck Pin Again

The best repair is the one you never have to make. A few minutes of preventative maintenance can save you hours of frustration down the road.

The Power of Anti-Seize Lubricant

This is the single most effective step you can take. Before installing a new shear pin, apply a thin coat of marine-grade anti-seize compound to both the pin itself and the inside of the shaft hole. This specialized lubricant creates a barrier that prevents moisture intrusion and stops galvanic corrosion before it can start, ensuring the pin can be easily removed next time.

Regular Inspection and Replacement

At the beginning of each winter season, take a few minutes to inspect your shear pins. If they show any signs of rust or wear, replace them proactively. It’s much easier to remove a pin that isn’t seized solid.

Proper Storage Techniques

At the end of the season, store your snow blower in a dry location like a garage or shed. If it must be stored outdoors, use a high-quality, waterproof cover to protect it from the elements and minimize moisture exposure.

Beyond the Pin: Tackling Other Common Snow Blower Issues

Fixing a stuck shear pin is a major accomplishment, but sometimes it reveals other underlying problems. For instance, after getting the auger spinning again, you might find your snowblower won’t start after cleaning the carburetor. This often points to a separate fuel delivery or ignition issue that needs to be addressed.

Keeping your machine in top running order involves being aware of these interconnected systems. A well-maintained engine and fuel system ensure you have the power you need, while functional shear pins ensure that power is applied safely.

Frequently Asked Questions About Snow Blower Shear Pins

Can I use a nail or a different sized bolt instead of a shear pin?

No, absolutely not. A nail or incorrect bolt lacks the specific shear strength of an OEM pin. This will almost certainly lead to severe damage to your snow blower’s gearbox when the auger inevitably jams on an obstacle.

How often should I replace my shear pins?

There’s no set schedule. You only need to replace them when they break. However, it’s wise to inspect them at the start of each season for rust and consider replacing them if they look heavily corroded to avoid a future removal headache.

Why do my shear pins keep breaking?

Frequent breaking can be caused by several things: trying to clear snow too quickly, hitting hidden objects like rocks or ice chunks, or using low-quality aftermarket pins. Always clear your driveway of obstacles before a snowfall and advance at a steady pace, allowing the machine to work effectively.

Conclusion: You’ve Mastered the Stuck Shear Pin

Facing a stuck snow blower shear pin can be an intimidating task, but it is entirely manageable with the right tools, techniques, and a healthy dose of patience. By following the methods outlined in this guide—from applying penetrating oil to carefully drilling—you can overcome even the most stubborn pin.

Remember that the most crucial steps are using the correct OEM replacement pin and applying anti-seize lubricant to prevent future seizures. A few moments of preventative care will ensure your snow blower is always ready to tackle the worst of winter, keeping you clear, safe, and frustration-free.