Shower on Exterior Wall: The #1 Mistake Causing Frozen Pipes & Mold

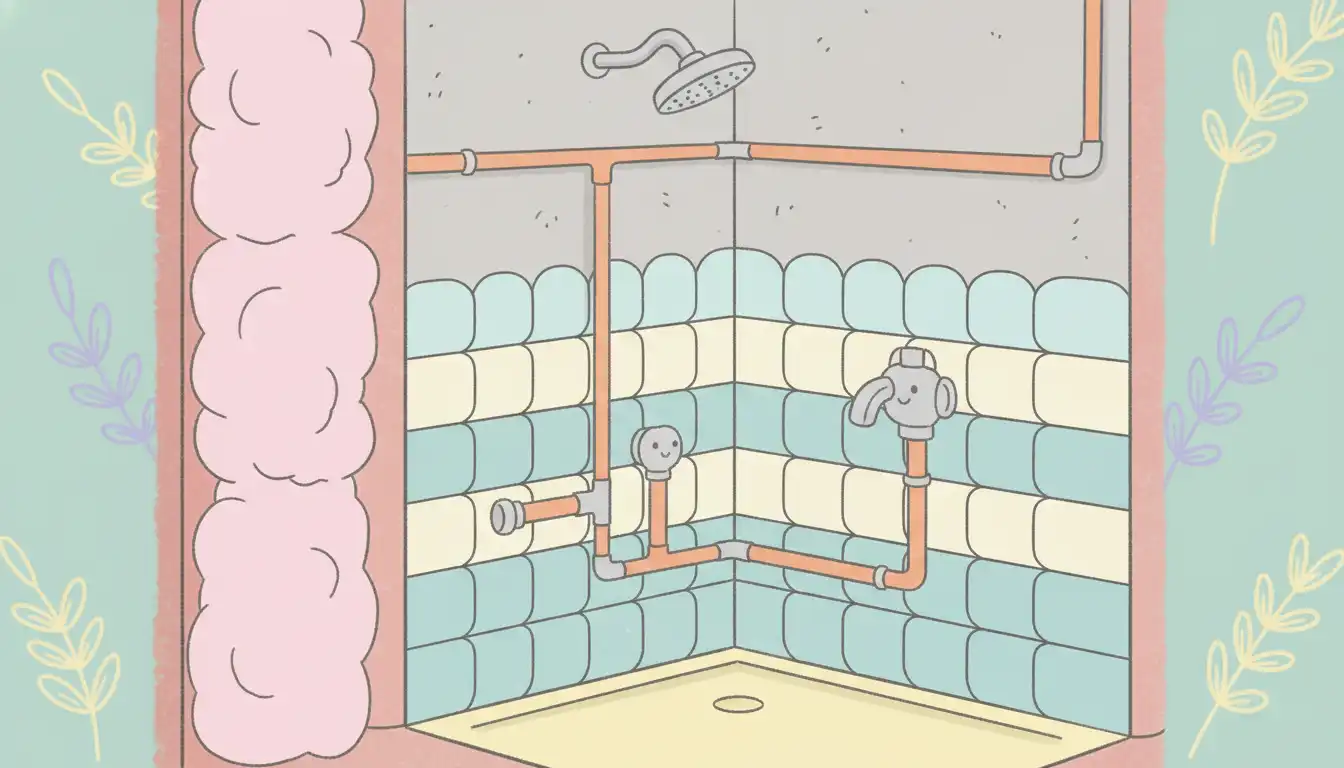

Placing a shower on an exterior wall can be a smart design choice, maximizing floor space and opening up layout possibilities. However, this decision comes with a serious set of risks that are often overlooked. Without meticulous planning and execution, you could be facing a catastrophic trifecta of problems: frozen pipes, rampant mold growth, and significant energy loss.

The core issue is simple physics. Your warm, steamy shower creates a massive temperature and moisture differential against a cold exterior wall. This battle between hot and cold, wet and dry, happens inside a wall cavity you can’t see, leading to disastrous consequences that can cost thousands in repairs. This isn’t just a construction choice; it’s a high-stakes engineering challenge that demands perfection.

You'll Learn About

The Cold Truth: Why Your Exterior Wall Hates Your Shower

Understanding the risks is the first step to mitigating them. Building codes in many cold climates strictly regulate or outright discourage placing plumbing in exterior walls for several critical reasons. When you place plumbing in this vulnerable location, you are inviting problems that can compromise your home’s structural integrity and air quality.

The most immediate and destructive threat is frozen pipes. Water supply lines routed through a poorly insulated exterior wall are highly susceptible to freezing temperatures. As water freezes, it expands, creating immense pressure that can easily burst even the strongest copper or PVC pipes, leading to major water damage.

Just as dangerous, but far more insidious, is condensation. Warm, moist air from your shower penetrates the wall cavity and hits the cold surface of the exterior sheathing. This causes water vapor to condense into liquid water inside your wall, saturating the insulation and wood studs, creating the perfect breeding ground for mold and rot.

The Ultimate Guide to a Fail-Proof Exterior Wall Shower

Successfully installing a shower on an exterior wall is entirely possible, but it requires a “belt-and-suspenders” approach that goes far beyond standard construction practices. The goal is to create a super-insulated, completely waterproof, and air-sealed assembly that keeps the plumbing entirely within the warm, conditioned envelope of your home.

Step 1: Build a “Wall-Within-a-Wall” for Plumbing

The single most effective strategy is to build a secondary 2×4 interior wall, often called a “wet wall” or “plumbing chase,” spaced about an inch off the main exterior wall. This creates a dedicated cavity for all your plumbing—supply lines, drain pipes, and the shower valve—ensuring they are never in direct contact with the cold zone of the exterior wall assembly. This method effectively moves the plumbing inside your home’s thermal boundary.

This approach completely isolates your pipes from the cold, making it the gold standard for preventing frozen pipes. For those with space constraints, an alternative is to frame the exterior wall with 2×6 studs instead of 2x4s. This provides a deeper cavity, allowing for more insulation to be placed behind the pipes, though the double-wall method remains superior for total protection.

Step 2: Choose Your Insulation Wisely

The type of insulation you choose is arguably the most critical decision in this project. Standard fiberglass batt insulation is not sufficient for this application as it is permeable to air and can hold moisture if it gets wet. Your two primary choices for high-performance insulation are closed-cell spray foam and rigid foam boards.

Closed-cell spray foam (CCSF) is the premium choice. When professionally installed, it expands to fill every crack and crevice, creating a powerful, monolithic barrier. Crucially, CCSF has a very low vapor permeance, meaning it acts as its own vapor barrier, and it is also an air barrier, stopping humid interior air from ever reaching the cold exterior sheathing. Its high R-value per inch (around R-7) provides maximum thermal resistance in a limited space.

Rigid foam boards (XPS or Polyiso) are a more DIY-friendly alternative. These boards should be cut to fit snugly between the studs and meticulously sealed at all seams with high-quality construction tape and around the edges with canned spray foam. This diligence is necessary to create a continuous air and vapor barrier equivalent to professionally installed CCSF.

| Insulation Type | Key Benefit | Primary Drawback | Best For |

|---|---|---|---|

| Closed-Cell Spray Foam (CCSF) | Highest R-value; acts as air & vapor barrier. | Requires professional installation; higher cost. | The “no-compromise” solution for maximum protection. |

| Rigid Foam Board (XPS/Polyiso) | Good R-value; DIY-friendly installation. | Requires meticulous air sealing of all seams. | DIYers who are detail-oriented and patient. |

| Fiberglass Batts | Low cost; widely available. | Air-permeable; loses R-value if compressed or wet. | Not recommended for this application. |

Step 3: Perfect Your Plumbing & Waterproofing

Even with a perfectly insulated wall, plumbing details matter. All supply lines must be positioned on the warm side of the insulation, closest to the interior of the bathroom. Using PEX-A tubing can provide an extra layer of security, as its flexibility makes it more resistant to bursting than rigid copper if freezing does occur.

Once the wall is closed up, the waterproofing phase begins. The tile substrate, typically cement board, is not waterproof on its own. You must apply a topical waterproofing membrane, either a liquid-applied product or a sheet membrane system. This creates a continuous waterproof surface that directs all water down into the shower drain, ensuring no moisture ever reaches the wall cavity from the front.

Moisture & Vapor Dynamics — The Overlooked “Drying Potential” Factor

One crucial issue that rarely gets discussed is the wall’s ability to dry out over time. Even with a perfectly insulated and tightly sealed exterior-wall shower, moisture can still find its way into the assembly—through tiny leaks, vapor diffusion, or small imperfections in waterproofing. If the wall has no way to release that moisture, it can become a long-term trap that slowly damages the structure.

Walls don’t just need to keep water out—they must also be able to let water escape. When multiple impermeable layers are stacked together (like foam board, vapor barriers, waterproof membranes, and non-breathable siding), you can accidentally create a “vapor sandwich” that locks moisture inside the wall. Over years, this trapped moisture can degrade insulation, rot wood framing, and allow hidden mold colonies to grow in places you’ll never see until it’s too late.

To prevent this, it’s important to design the shower wall with intentional drying pathways. Depending on your climate, this may mean allowing drying to the exterior through breathable sheathing and a ventilated rain screen, or allowing controlled drying to the interior using vapor-smart membranes. The key is balance: the wall must block bulk water and humid indoor air—but still have at least one direction where moisture can safely escape.

This concept applies in every climate. In cold regions, it protects against winter condensation. In hot and humid regions, it prevents moisture buildup from inward vapor drive. Modern, airtight homes are especially vulnerable because they lack the natural air leakage that used to help walls dry by accident.

Building a shower on an exterior wall isn’t just about insulation and waterproofing—it’s also about ensuring the wall can dry, slowly and safely, for the life of the home.

Frequently Asked Questions & Smart Alternatives

Navigating the complexities of a shower on an exterior wall often brings up specific questions. Whether you’re dealing with a unique climate or looking for alternative designs, having clear answers is essential for a successful project.

What if I live in a warm climate without freezing temperatures?

Even if you don’t face the risk of frozen pipes, the principles of insulation and vapor control are still critical. A hot shower will create a temperature difference against an air-conditioned wall, leading to condensation within the wall cavity. Proper insulation and a robust vapor barrier are essential to prevent mold and rot, regardless of your climate.

Are there alternatives if I can’t rebuild the wall?

If extensive framing work isn’t feasible, consider design alternatives. You might be able to create a shallow interior bump out wall just large enough to house the plumbing. This achieves the same goal of moving the pipes into the conditioned space without requiring a full double-wall construction. Another option is to route plumbing through an adjacent interior wall, the floor, or the ceiling to reach the shower fixtures.

Can a window be placed in an exterior shower wall?

Yes, but it adds another layer of complexity. A wood window in a shower requires flawless waterproofing of the window unit itself, the rough opening, and the surrounding wall. Vinyl or fiberglass windows are superior to wood in this wet environment, and specialized waterproofing kits are essential to integrate the window into the rest of the shower’s waterproof membrane.

Your Exterior Wall Shower: A Luxury That Demands Perfection

A shower on an exterior wall can be a functional and beautiful addition to your home, but it is an unforgiving project. There is no room for error. The potential for catastrophic failure from frozen pipes or hidden mold growth means that every step, from framing to insulation to waterproofing, must be executed perfectly.

By committing to a superior design—like the double-wall method—and investing in high-performance materials like closed-cell spray foam, you can mitigate the inherent risks. This transforms a potential liability into a durable, comfortable, and energy-efficient feature of your home that you can enjoy with complete peace of mind.