Redirect Outside Dryer Vent: Your #1 Guide to a Safer Home

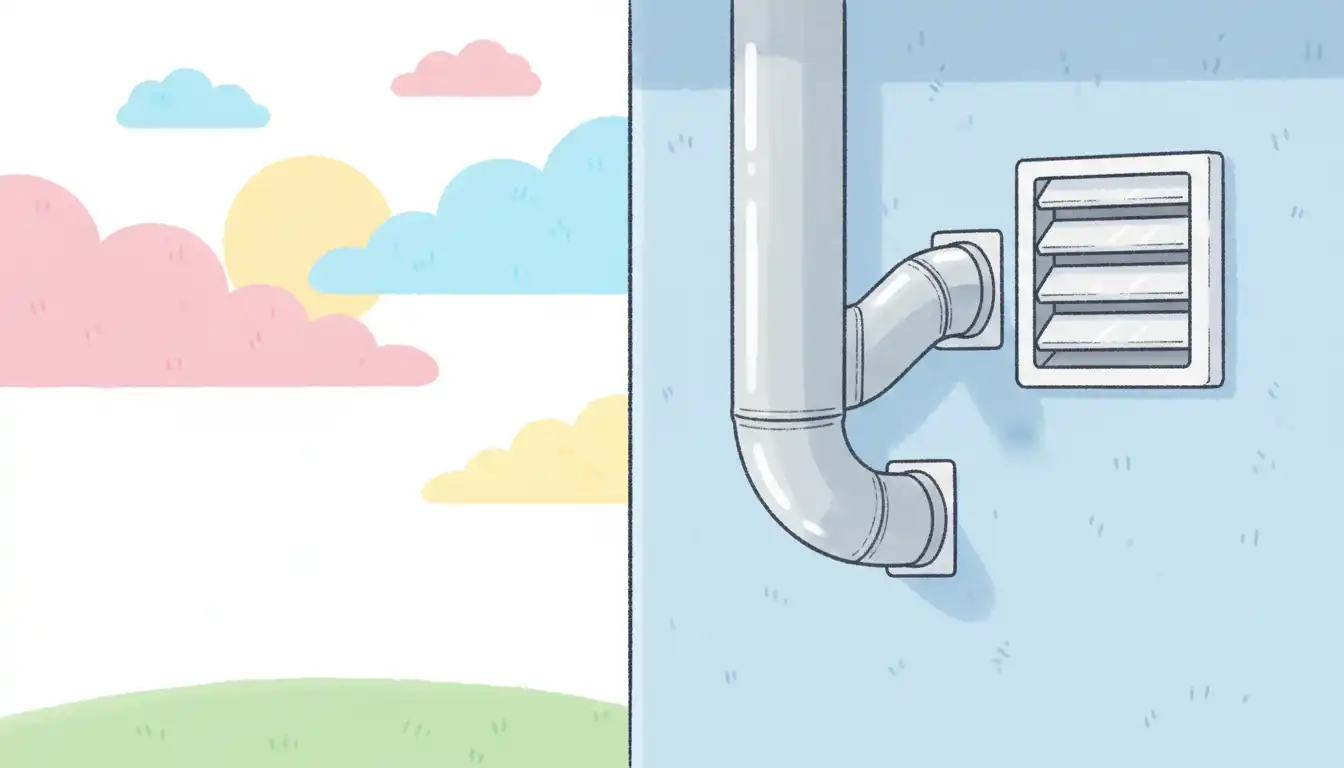

Is your dryer vent in the wrong spot? Many homeowners overlook this critical detail, not realizing a poorly placed vent can be a serious fire hazard and energy drain.

This guide will show you exactly how to redirect your outside dryer vent for improved safety and efficiency.

You'll Learn About

Why Your Current Dryer Vent Location Is a Hidden Danger

The location of your dryer’s exhaust vent is not just about convenience; it’s a critical component of your home’s safety system. A vent that terminates in the wrong place can lead to a host of problems that are easy to ignore but dangerous to neglect.

When a vent is too close to a window, door, or air conditioning unit, it can pump hot, moist, lint-filled air directly back into your home. This not only defeats the purpose of the vent but can also lead to mold growth and poor indoor air quality.

The Invisible Threat of Poor Airflow

The most significant danger of a poorly routed dryer vent is restricted airflow. Long, winding paths with multiple sharp turns create resistance, slowing down the exhaust air and causing lint to accumulate inside the ductwork.

This buildup is highly flammable and is a leading cause of house fires. If your clothes take longer and longer to dry, it’s a clear warning sign that your vent is clogged and needs immediate attention.

Moisture Damage and Pest Infestations

A dryer vent that terminates under a deck, in a crawlspace, or too close to the ground can cause significant moisture damage to your home’s structure. The warm, damp environment is a perfect breeding ground for mold, mildew, and wood rot.

Furthermore, a poorly sealed or damaged vent cap provides an easy entry point for rodents, birds, and insects. Redirecting the vent to a proper location with a secure cap is essential for keeping pests out.

Key Signs That You Must Redirect Your Dryer Vent

It’s not always obvious that your dryer vent is the source of a problem. However, there are several tell-tale signs that indicate an urgent need for redirection or rerouting.

Ignoring these warnings can lead to appliance failure, property damage, or even a devastating fire. Paying attention to your dryer’s performance is the first step toward a safer home.

Long Drying Times and Overheating

The most common symptom of a blocked or inefficient vent is a noticeable increase in drying time. If you have to run a second or third cycle to get your clothes dry, poor ventilation is almost always the culprit.

When air cannot escape efficiently, heat and moisture get trapped in the dryer drum and the vent line. This forces the appliance to work harder, leading to overheating and premature failure of its components.

Visible Lint and a Burning Smell

Check the area around your exterior vent cap. If you see a significant accumulation of lint on the wall or ground, it means the vent is not expelling air forcefully enough to clear the debris.

A faint burning smell while the dryer is running is a major red flag. This often indicates that lint trapped in the ductwork or inside the dryer itself is scorching from the heat, putting you at immediate risk of a fire.

The Non-Negotiable Rules of Dryer Venting

Before you begin any project, it’s crucial to understand the building codes and safety standards that govern dryer vent installation. These rules are in place to prevent fires and ensure your appliance operates efficiently.

Following these guidelines is not optional. Adhering to code requirements is the most important part of the job.

Understanding Maximum Duct Length

Most building codes, including the International Residential Code (IRC), specify a maximum length for a dryer duct run. This is typically 35 feet from the back of the dryer to the exterior vent termination.

However, this maximum length is reduced for every bend in the pipe. A 90-degree elbow is equivalent to 5 feet of straight pipe, and a 45-degree elbow is equivalent to 2.5 feet.

| Duct Material | Pros | Cons | Best Use Case |

|---|---|---|---|

| Rigid Metal Duct | Smooth interior prevents lint buildup; excellent airflow; most fire-resistant. | More difficult to install; requires precise measurements and cutting. | The entire duct run, especially for long or complex paths. The gold standard for safety. |

| Semi-Rigid Metal Duct | Flexible and easier to install than rigid ducts; holds its shape well. | Corrugated interior can trap some lint; more fragile than rigid ducts. | Transitions and tight spaces, like the connection directly behind the dryer. |

| Vinyl or Foil Duct | Very flexible and easy to manipulate. | Highly flammable; easily crushed, restricting airflow; traps massive amounts of lint. Banned by most building codes. | Should NEVER be used. Only included for comparison and as a warning. |

How to Redirect Your Outside Dryer Vent: A Step-by-Step Guide

Redirecting a dryer vent is a manageable DIY project for those with basic carpentry skills. The key to success is careful planning and using the correct materials. Never compromise on safety.

This guide will walk you through the process from start to finish, ensuring a safe and efficient installation.

Step 1: Plan the New Vent Path

Your primary goal is to create the shortest, straightest path possible from the dryer to the outside. Use a tape measure to determine the length of the new run and count the number of turns you’ll need.

Remember to subtract the equivalent length for each elbow from your total maximum of 35 feet. Choose a termination point that is at least 3 feet away from any doors, windows, or HVAC intakes.

Step 2: Gather Your Tools and Materials

You will need a 4-inch diameter rigid metal duct, 4-inch elbows, a new exterior vent cap, foil-backed tape, a drill, a 4.25-inch hole saw, and exterior-grade caulk. Do not use duct tape or screws to connect the duct sections, as they can trap lint.

Ensure all materials are rated for dryer vent use. Using the wrong products can create a serious hazard.

Step 3: Disconnect and Remove the Old Vent

Unplug your dryer and, if it’s a gas model, shut off the gas supply. Carefully pull the dryer away from the wall and disconnect the old vent duct from the back of the appliance and the wall.

Remove all accessible sections of the old ductwork. Sometimes, finding the entire path can be tricky; if you can’t find the dryer vent path, you may need to inspect your crawlspace or attic.

Step 4: Create the New Exterior Opening

From inside, drill a small pilot hole through the exterior wall at the center of your planned exit point. This helps you locate the spot from the outside and ensure it’s free of obstructions.

Using the pilot hole as a guide, use a 4.25-inch hole saw to cut the new opening from the outside in. This larger size ensures the duct pipe will fit through easily.

Step 5: Install the New Ductwork

Starting from the dryer, begin assembling the rigid duct sections. Use a male-to-female connection pattern so the crimped (male) end points in the direction of the airflow, preventing lint from catching on the seams.

Seal every joint and seam thoroughly with foil-backed tape. This creates an airtight seal that prevents moisture and lint from escaping into your walls. This process is very different from a kitchen exhaust, where a range hood vent not aligned can cause similar airflow issues but with greasy air instead of lint.

Step 6: Secure the Exterior Vent Cap

Insert the tailpiece of the new vent cap into the opening from the outside, connecting it to the final section of the duct. Secure the cap to the exterior wall with screws.

Apply a generous bead of exterior-grade caulk around the perimeter of the vent cap flange. This creates a weatherproof seal that prevents water and pests from entering your home.

Step 7: Permanently Seal the Old Vent Hole

It is absolutely critical to properly seal the old exterior opening. Simply covering it is not enough. Fill the wall cavity with insulation to restore the thermal barrier.

Patch the interior wall with drywall and the exterior wall with appropriate siding or masonry repair materials. This prevents energy loss, moisture intrusion, and pest entry.

Common Mistakes to Avoid at All Costs

A simple mistake during a vent redirection project can negate all your hard work and create a new set of hazards. Avoiding these common pitfalls is essential for a successful installation.

Think of the project as a complete system. Every component must work together perfectly to ensure safe and efficient operation.

Using Flexible Vinyl Ducting

The single biggest mistake is using a flammable, flexible vinyl or foil duct. This material is often sold as a “dryer vent kit” but is a known fire hazard that is prohibited by virtually all building codes for use within a wall.

Always use rigid or semi-rigid metal ducting for the entire run. Its smooth interior surface allows lint to pass through freely, and it will not sustain a fire.

Creating Long, Complex Runs

Exceeding the maximum recommended length or using too many elbows will kill your dryer’s performance and create a fire risk. Airflow loses momentum with every foot and every turn.

If a short, direct path isn’t possible, you may need to consider a different solution. Sometimes, the best option is to move your washer and dryer to a location that allows for a proper vent installation.

Advanced Considerations for Complex Reroutes

Some homes present unique challenges that require more than a standard redirection. Obstructions within walls or exceptionally long vent paths may require special planning and components.

Understanding these challenges is key. You might encounter a situation that turns a simple project into a complex one requiring professional help.

Navigating In-Wall Obstructions

When planning your new vent path, you must consider what’s inside the walls. Electrical wiring, plumbing pipes, and structural elements can all be in the way.

In homes with gas appliances, it’s particularly important to be aware of where lines are located. Accidentally drilling into a gas line in the wall can have catastrophic consequences. Always use a stud finder with AC/pipe detection capabilities.

When to Use a Dryer Booster Fan

If your required duct run exceeds the 35-foot maximum length (after accounting for elbows), you will need a dryer booster fan. These in-line fans are installed within the duct run to help push the air to the exterior.

Booster fans must be installed correctly to be effective and should be interlocked with the dryer’s operation. They also require periodic cleaning, just like the main duct line.

Conclusion: A Simple Project for a Safer, More Efficient Home

Redirecting your outside dryer vent is more than just a home improvement task; it’s a critical safety upgrade. By ensuring a short, direct, and properly sealed vent path, you dramatically reduce your risk of a house fire.

You’ll also enjoy the benefits of a more efficient appliance, leading to shorter drying times and lower energy bills. It’s a weekend project that pays dividends in both safety and savings for years to come.