What is Old Boiler 52? Error? Any Solve? Here’s What We Found

Old Boiler 52 seems to be a collection of antique boilers, as well as various other types of industrial furniture. But this might be an error that you need to solve. Let’s find out in this discussion.

You'll Learn About

Common Old Boiler Issues With 52 Error

Old boilers Steam Boiler, Cannon, Submarine, Industrial Furniture, Olds Rusty…

This appears to be an incomplete or repeated statement regarding antique industrial equipment and furniture such as steam boilers and cannons.

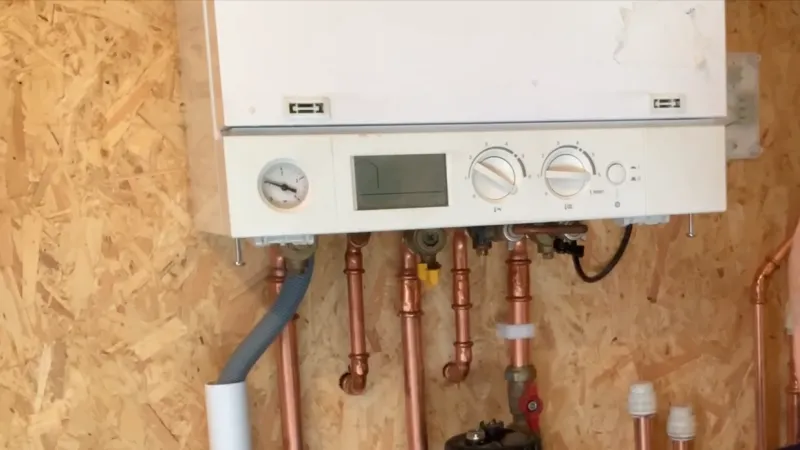

When a boiler stops working, it usually displays a fault or error code. F.52 – Faulty mass flow sensor connection. No mass flow sensor.

Boilers may malfunction, resulting in an error message detailing what exactly went wrong with the unit. For example, “F.52” refers to a mass flow sensor that has been disconnected on some boiler types.

These topics summarize three major points about typical boiler problems:

- First, we’ll go over what these reoccurring issues are and what their names are. (list)

- Then explain how each one affects performance. (explanation)

- Before ending by providing alternative solutions that homeowners might try on their own,(Test)

Fault Codes and Error Messages

There are several types of boilers, including steam boilers, cannons, and submarines, to name a few. Especially antique ones, which may be interesting to investigate because they were widely used before new technology changed the sector.

One common issue with boilers when they stop working is being represented by fault codes or error messages. This allows users, such as homes or businesses, to rapidly identify what’s wrong and supply remedies.

A disconnected cable causes the F52 mass flow sensor connection to fail. Checking wire connections should resolve this issue, while larger issues may necessitate the participation of experts known as troubleshooters.

In general, codes like this help us better understand defective hot water systems. Explaining boiler problems necessitates a thorough understanding of how these devices operate.

As a result, having some notion about troubleshooting step-by-step according to the offered setup instructions is beneficial. It is critical if we intend to do it ourselves. If you’re having one of these problems, don’t ignore it.

Understanding how it works will save you time, and money, and keep you safe. Most importantly, utilize reliable equipment because ineffective equipment causes more harm than good over time.

Maintenance and Upkeep

When a boiler stops working it generally shows a fault code or error code…

If something goes wrong with your boiler system at home or at work, causing it to malfunction, the display will most likely show you certain codes indicating that there is an issue with the equipment itself.

F.52, for example, denotes a mass flow sensor connection problem. This signals a disconnect from the strainer/filter, preventing water from flowing properly through the pipelines until the problem is resolved quickly.

Maintenance and Upkeep

Importance of maintaining boilers

Regular maintenance habits can ensure better performance efficiency from your heating systems without any random breakdown during wintertime; also prolonging their lifespan minimizes repair costs over time too.

Tips for maintaing an old boiler

When caring for an older model unit rather than replacing it every few years, certain procedures must be followed. Because they are inefficient, replacing them with new ones would be more expensive in the long run.

They go a long way toward eliminating superfluous DPC layouts and saving money on long-term repairs if left unchecked while keeping regular inspections on rusted sections built correctly.

Again, would not have encountered otherwise.

How to prolong lifespan of old Boilers

The amount of able-run elements required to convert your dying furnace into a nearly-new one impacts life expectancy. It will continue to operate rough after an inspection and general upkeep, improving the likelihood of an extended lifespan.

You should avoid being unprepared or uninformed of any complications that may come down the road.

Upgrading to a New Boiler

When a boiler stops working, it usually displays a defect or error code… F.52 – Mass flow sensor connection error – Mass flow sensor not connected.

Problems with boilers can create malfunctions, causing them to stop performing properly. Most newer units have system devices fitted. When something goes wrong during operation, an error message is displayed to allow for speedy troubleshooting.

For example, the F 52-error shows a problem with the connections of mass airflow sensors: There could be a problem connecting these components or sensing fuel levels within combustion chambers.

Because of erroneous readings from these same components (not reading temperatures). Then, one specific warning notice denoted by “F52.” will appear on your device’s screen.

It informs you of a failure discovered by the indicated components.

Upgrading to New Boiler

Cost Comparison between Repairing Vs.upgrading the boiler

There comes a time when replacing our home appliances is required for increased convenience and efficiency in our homes. We also need new furnaces if repairs are only temporary fixes.

Furthermore, renovations frequently make financial sense in terms of saving money while improving energy outputs. Because the cost of replacing broken-after-use always exceeds the cost of repair.

giving priority maintenance schedule vital. Currently, many varieties of cutting-edge technologically advanced models have made their way into marketplaces, each tailored to specific needs and budgets.

For example, SMART boilers can manage the temperature of individual rooms via a smartphone or tablet interface.

Cost comparisons between fixing and upgrading are affected by age and model, since certain new/complex models may cost substantially more than simple adjustments for older systems, while upkeep plays a vital part in operating lifespan.

Choosing the best solution may necessitate expert advice that takes into account these fees as well as other current situations. It has to do with your boiler setup.

Purchasing and installing brand-new heaters is a significant investment choice. However, it pays off in the long run due to lower energy expenditures. It will assist you in conserving money that often eclipses practically all expenses acquired while owning gadgets over the long term.

Old Boiler 52

History of Old Boiler 52

When boilers stop working they generally show an error code or fault code.

Old Boiler 52 refers to one such boiler that was once used in the industry but is now considered outdated.

Description of Old Boiler 52

It is an old steam boiler which had many industrial uses from powering machinery to heating buildings.

Significance of Old Boiler 52 in the Industry

It has historical significance as part of the early development of industrial technology. Because of its inefficiencies and excessive emissions output, this boiler model is no longer suitable for current use.

Finally, while Steve Lutz’s promotion recognizes his accomplishments as a distinguished member of his field. However, certain types, such as “Old Boilers,” notably “Boiler Number #53,” detailed here, have had a significant impact on the industry.

Despite its vital contribution to earlier advancements on multiple fronts, it becomes obsolete over time. Thus, from architectural fittings to the development of steam engines.

It serves beyond limitations, repelling any barriers that appear on the victory side throughout time.” Sometimes you might fetch a receiver drier freezing during recovery, which you can solve easily.

To Recap

Without further context on Old Boiler 52, it’s challenging to draw any concrete conclusions about its significance or purpose. It appears that Steve Lutz has recently moved up in college coaching ranks but otherwise does not seem related to Old Boiler 52.

Additionally, the mention of fault codes suggests an informational resource for troubleshooting faulty modern-day boilers rather than antique and rusted ones found within this collection.