No Gas in Carburetor Bowl? The Real Reason Your Engine Won’t Start

There are few things more frustrating than an engine that refuses to start. You pull the cord or turn the key, expecting the familiar roar, but get nothing but silence or a weak sputter. You know there’s fuel in the tank, but the engine is acting like it’s completely starved.

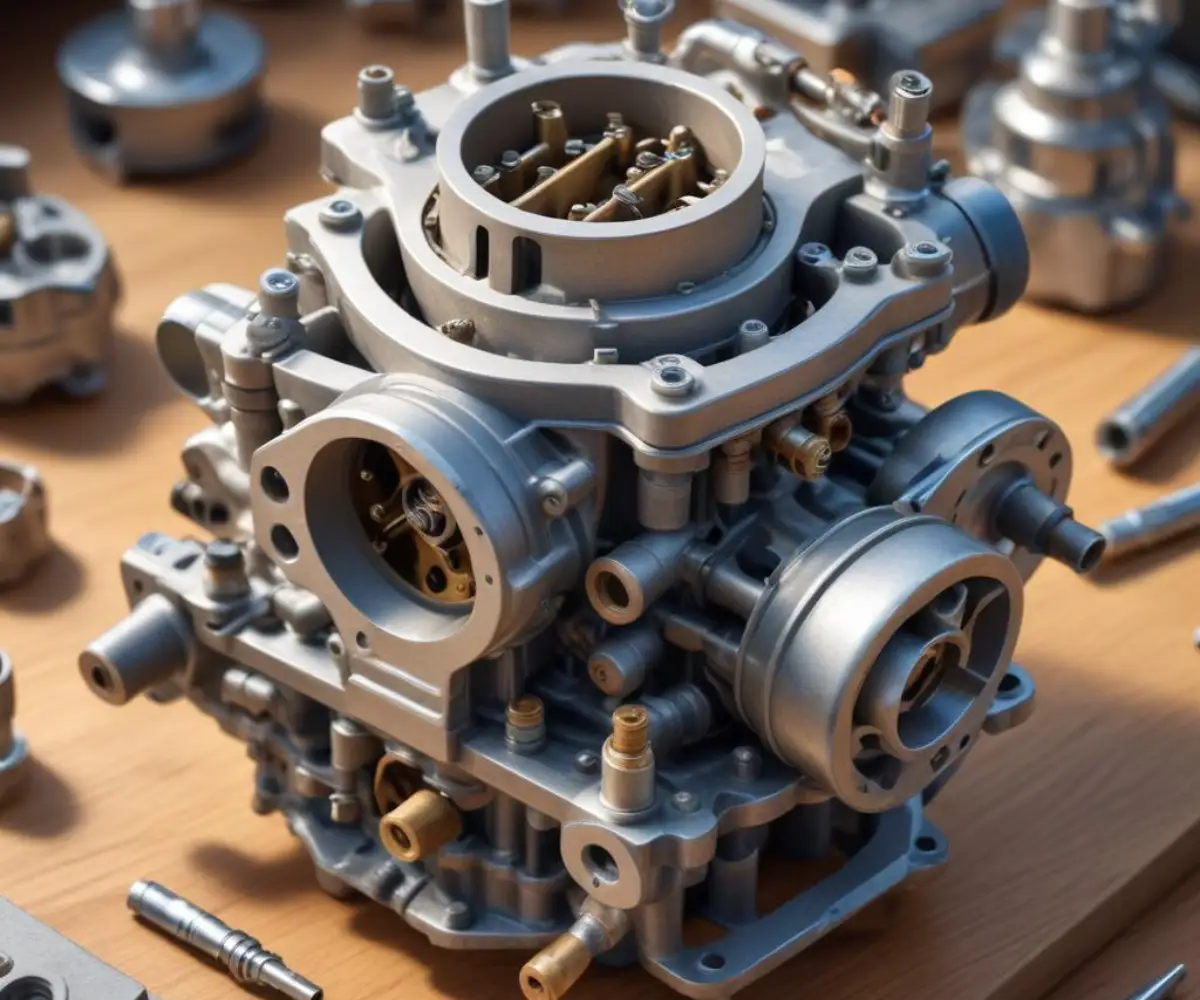

This common and maddening problem often points to one specific issue: an empty carburetor bowl. The carburetor bowl is a small reservoir that holds a ready supply of gasoline, and if it’s dry, your engine has no fuel to draw from. Understanding why this happens is the key to a quick and permanent fix.

This guide will walk you through a systematic process to diagnose and solve the root cause of an empty carburetor bowl. We will move from the simplest checks to the more detailed repairs, empowering you to get your small engine running smoothly again. This isn’t just a temporary fix; it’s about understanding the fuel system to prevent future failures.

You'll Learn About

Why Your Carburetor Bowl Is Empty: Uncovering the Root Cause

Think of your engine’s fuel system as a river. The fuel tank is the source, and the engine’s combustion chamber is the destination. The carburetor is a critical dam and lock system along this river, precisely regulating how much fuel gets through.

If the small reservoir in this system—the carburetor bowl—is empty, it means there’s a blockage somewhere upstream. The problem can be traced back to one of three main areas: the fuel tank itself, the delivery path (lines, filter, pump), or the carburetor’s inlet mechanism. We will explore each of these potential failure points in detail.

The First Point of Failure: Is Fuel Escaping the Tank?

Before you start disassembling components, always begin with the simplest and most overlooked checks at the fuel tank. Many “no-start” issues are resolved right here in a matter of minutes. These simple steps can save you hours of unnecessary work.

These initial checks are crucial because they address the fundamental requirement for the engine to run: fuel must be able to leave the tank. If it can’t, no other part of the system matters. Often, the solution is surprisingly simple.

The Hidden Culprit: A Blocked Gas Cap Vent

One of the most frequently ignored causes of fuel starvation is a clogged gas cap vent. For fuel to flow out of the tank, air must be able to get in to replace it. If the vent is blocked, a vacuum forms inside the tank, effectively holding the fuel in place.

This is a subtle issue that mimics more complex problems. You can easily test for it by slightly loosening the gas cap and trying to start the engine. If the engine fires up or fuel suddenly flows, you’ve found your problem. The solution is to either thoroughly clean the vent hole in the cap or simply replace the cap entirely.

Is the Fuel Shut-Off Valve Actually Open?

It may sound basic, but it happens to everyone. The fuel shut-off valve can easily be bumped into the closed position during transport or storage. Always double-check that the valve is fully open, allowing fuel to flow out of the tank.

To confirm flow, you can place a catch can under the fuel line, disconnect it from the carburetor, and open the valve. A steady stream of fuel should flow out. If it doesn’t, and you’ve already checked the gas cap, the blockage is likely inside the tank or at the valve’s outlet screen.

The Damaging Effects of Stale and Degraded Fuel

Modern gasoline, especially ethanol-blended fuels, can cause significant problems when left for long periods. The ethanol attracts moisture, leading to corrosion, while the gasoline itself degrades and forms a thick, sticky varnish. This is why using something like E10 gas in your pressure washer or other seasonal equipment can be a critical mistake without a fuel stabilizer.

This gummy residue can clog the fuel tank’s outlet screen, the shut-off valve, and every other component downstream. If you suspect old fuel is the issue, the only solution is to completely drain the tank and clean it thoroughly before refilling with fresh, stabilized gasoline.

Tracing the Blockage: Diagnosing the Fuel Delivery Path

If you’ve confirmed that fuel can and does leave the tank, but it’s still not reaching the carburetor, the problem lies in the delivery system. This includes the fuel lines, the fuel filter, and, on some larger engines, a fuel pump. Each of these components can become a chokepoint.

A methodical inspection of this path is the next logical step. Finding the blockage here is often straightforward and involves simple, inexpensive parts. This process will isolate the problem and bring you closer to the final solution.

The Unseen Guardian: Your Fuel Filter

The fuel filter is designed to be the single point of failure to protect the more sensitive carburetor components. Over time, it does its job by trapping debris and sediment. Eventually, it can become so clogged that it completely blocks the flow of gasoline.

Visually inspect the filter. If you see a lot of sediment inside, it’s time for a replacement. A quick test is to disconnect the fuel line from the filter’s outlet side; if fuel flows to the filter but not out of it, the filter is clogged. Replacement is the best and only course of action, as cleaning is often ineffective.

Cracked, Pinched, or Clogged Fuel Lines

The flexible fuel lines that carry gasoline from the tank to the carburetor can degrade over time. They can become brittle and crack, causing leaks, or they can soften and collapse internally or get pinched, restricting flow. Run your fingers along the entire length of the fuel line, checking for any hard, soft, or kinked spots.

Even if a line looks fine externally, it can be clogged internally with the same varnish that affects the fuel tank. The best test is to disconnect the line from the carburetor inlet and check for a healthy flow of fuel. If the flow is weak or nonexistent, and you have a new filter, the line itself is the likely culprit.

When Your Engine Has a Fuel Pump

While many gravity-fed small engines don’t have one, larger or more complex engines often use a vacuum-pulse fuel pump to move fuel from a low-mounted tank. These pumps are generally reliable but can fail. A ruptured diaphragm is a common point of failure.

To test the pump, disconnect the fuel line from the carburetor inlet and place it into a container. Crank the engine over a few times. You should see distinct pulses of fuel being ejected from the line. If you get little or no fuel, the pump has likely failed and will need to be rebuilt or replaced.

The Final Frontier: Problems at the Carburetor Inlet

If you have confirmed strong fuel flow all the way to the carburetor’s inlet fitting, but the bowl remains empty, the problem is inside the carburetor itself. The issue lies with the mechanism designed to regulate fuel entry: the float and the inlet needle. This is the most common failure point in the entire system.

This internal mechanism is sensitive to even the smallest piece of debris. A tiny particle can hold the needle shut, preventing any fuel from entering the bowl. Fortunately, addressing this is often a simple matter of careful cleaning.

The Number One Cause: A Stuck Carburetor Float Needle

Inside the carburetor bowl, a float rises and falls with the fuel level. This float is connected to a small, pointed needle that plugs the fuel inlet when the bowl is full. If a piece of sediment or a flake of varnish gets lodged between this needle and its seat, it can hold the needle in the closed position, starving the engine of fuel.

A temporary diagnostic trick is the “tap test.” Using the plastic handle of a screwdriver, give the side of the carburetor bowl a few firm taps. This can sometimes dislodge the stuck needle, allowing fuel to flow. If the engine then starts, you have confirmed the problem, but a proper cleaning is still required for a reliable fix.

The Definitive Fix: Cleaning the Needle and Seat

To permanently solve a stuck needle, you must remove the carburetor bowl. This is typically held on by a single bolt or nut at the bottom. Once the bowl is off, you will see the float assembly, which is usually held in place by a single pin. Carefully slide this pin out to remove the float and the attached inlet needle.

Thoroughly spray the needle, the float, and the inlet seat (the hole the needle goes into) with carburetor cleaner. Use a soft brush to remove any residue. A blast of compressed air can ensure the inlet seat is completely clear before you reassemble everything. This single cleaning procedure solves the vast majority of empty-bowl issues.

A Less Common Issue: A Failed Float

While less common, the float itself can fail. Older brass floats can develop pinhole leaks, fill with gasoline, and sink, which would cause flooding rather than an empty bowl. However, modern plastic or composite floats can become saturated with fuel over time, losing their buoyancy and failing to drop down properly to open the inlet needle.

To check the float, simply remove it and shake it. If you hear liquid sloshing inside, it has failed and must be replaced. A faulty float can lead to inconsistent fuel levels, causing a range of problems from stalling to flooding. This is a crucial check when you have the carburetor apart.

Troubleshooting Flowchart: From Tank to Carburetor

Navigating fuel system issues can be confusing. This table provides a clear, step-by-step diagnostic guide to help you pinpoint the exact cause of your empty carburetor bowl. Follow these steps in order to avoid unnecessary work and quickly identify the true source of the problem.

| Symptom | Possible Cause | Quick Test | Solution |

|---|---|---|---|

| Engine won’t start, carb bowl is dry. | Clogged Gas Cap Vent | Loosen the gas cap slightly and see if fuel flows. | Clean the vent hole or replace the gas cap. |

| No fuel flow from the tank outlet. | Fuel Shut-Off Valve Closed / Clogged | Ensure the valve is open. Check for flow directly from the valve. | Open the valve. If still clogged, clean or replace the valve assembly. |

| Fuel flows from tank, but not through the filter. | Clogged Fuel Filter | Disconnect the line after the filter; check for flow. | Replace the fuel filter. Do not attempt to clean. |

| Fuel reaches the carburetor inlet but the bowl is still empty. | Stuck Float Inlet Needle | Gently tap the side of the carburetor bowl. | Remove the bowl and thoroughly clean the needle and seat. |

| Fuel delivery is intermittent or weak (on applicable engines). | Failing Fuel Pump | Disconnect the outlet line and crank the engine to check for pulses of fuel. | Rebuild the pump with a new diaphragm kit or replace the entire pump. |

Preventative Maintenance: How to Avoid Future Fuel Problems

Fixing the problem is one thing; preventing it from ever happening again is the ultimate goal. The majority of fuel system issues, especially those related to an empty carburetor bowl, are entirely preventable with proper maintenance and fuel management. A few simple habits can save you significant time and money.

An engine that won’t start can be a major headache, particularly with equipment like an Ariens Deluxe 24 that won’t start right before a snowstorm. Committing to these preventative measures ensures your equipment is reliable and ready to go when you need it most. These steps are the key to long-term engine health.

Always Use Fresh, Stabilized Fuel

The single most important thing you can do for your small engine’s fuel system is to use fresh fuel treated with a quality fuel stabilizer. Gasoline begins to degrade in as little as 30 days. A stabilizer prevents the formation of varnish and gum and protects against the harmful effects of ethanol.

Make it a habit to add stabilizer to your main gas can every time you fill it up. This ensures that all the fuel you use, in every piece of equipment, is protected. This simple step eliminates the primary cause of carburetor clogs.

Proper Long-Term Storage is Key

For seasonal equipment like lawnmowers or snowblowers, end-of-season storage is a critical moment. You have two excellent options. The first is to run the engine completely out of fuel until the carburetor is dry. The second, and often better, option is to fill the tank with stabilized fuel and run the engine for a few minutes to ensure the treated fuel circulates through the carburetor.

An empty carburetor cannot form varnish deposits. A carburetor full of properly stabilized fuel is also protected. Both methods are effective at preventing the sticky buildup that causes the float needle to get stuck in the first place.

Understand Your Machine’s Starting Procedure

Sometimes, what seems like a fuel problem can be a simple operational error. For instance, knowing how to properly use the choke is essential for cold starts. Fully understanding the meaning of the snowblower choke symbol and other controls ensures you are giving the engine what it needs to fire up.

Incorrectly using the choke can flood the engine or prevent it from getting the rich fuel mixture it needs to start. Always consult your owner’s manual to be certain you are following the correct procedure, as this can often be mistaken for a more serious mechanical fault.

When Is It Time to Call a Professional?

While most causes of an empty carburetor bowl are straightforward to fix, there are times when calling a professional is the best course of action. If you have followed all the diagnostic steps and still cannot get fuel into the bowl, there may be a more complex internal carburetor issue at play.

Additionally, if you are not comfortable disassembling a carburetor, it’s wise to seek expert help. A small engine mechanic has the tools and experience to quickly diagnose and repair the issue without causing any accidental damage. Knowing your limits is just as important as knowing how to do the repair.

Your Engine’s Lifeline: A Clean Fuel System

The journey of fuel from the tank to your engine is a critical one, and any interruption along that path will bring your machine to a halt. The frustrating discovery of an empty carburetor bowl is almost always a symptom of a blockage, most often caused by degraded fuel. By methodically checking the system from the tank cap to the float needle, you can effectively diagnose and resolve the issue.

More importantly, by embracing preventative maintenance—using fresh, stabilized fuel and practicing proper storage—you can ensure this problem never sidelines your equipment again. A clean, unobstructed fuel system is the lifeline of your engine, and keeping it that way guarantees reliability and performance for years to come.