Low-E 366 Problems: Is Your Perfect Window Flawed?

You invested in high-performance Low-E 366 windows, expecting crystal-clear views and lower energy bills. Instead, you’re staring at a frustrating haze, a strange tint, or subtle distortions that make your perfect view feel flawed. These premium windows are designed for ultimate solar control and year-round comfort, but homeowners sometimes encounter unexpected issues that can cause significant concern.

Understanding these potential problems is the first step toward finding a solution and ensuring you get the performance you paid for. From manufacturing residues to the physics of light, the causes are varied, but the solutions are often straightforward. This guide will walk you through the most common Low-E 366 problems, separating myths from manufacturing defects and providing clear, actionable steps to restore the clarity and efficiency of your windows.

You'll Learn About

The Haze Enigma: Why Do New Low-E Windows Look Dirty?

One of the most frequently reported issues with new Low-E 366 windows is a persistent haze, sometimes described as an oily sheen or a cloudy film. This can be particularly noticeable when direct sunlight hits the glass at a certain angle, making pristine new windows appear constantly dirty. While alarming, this haze is not always a sign of a defective product.

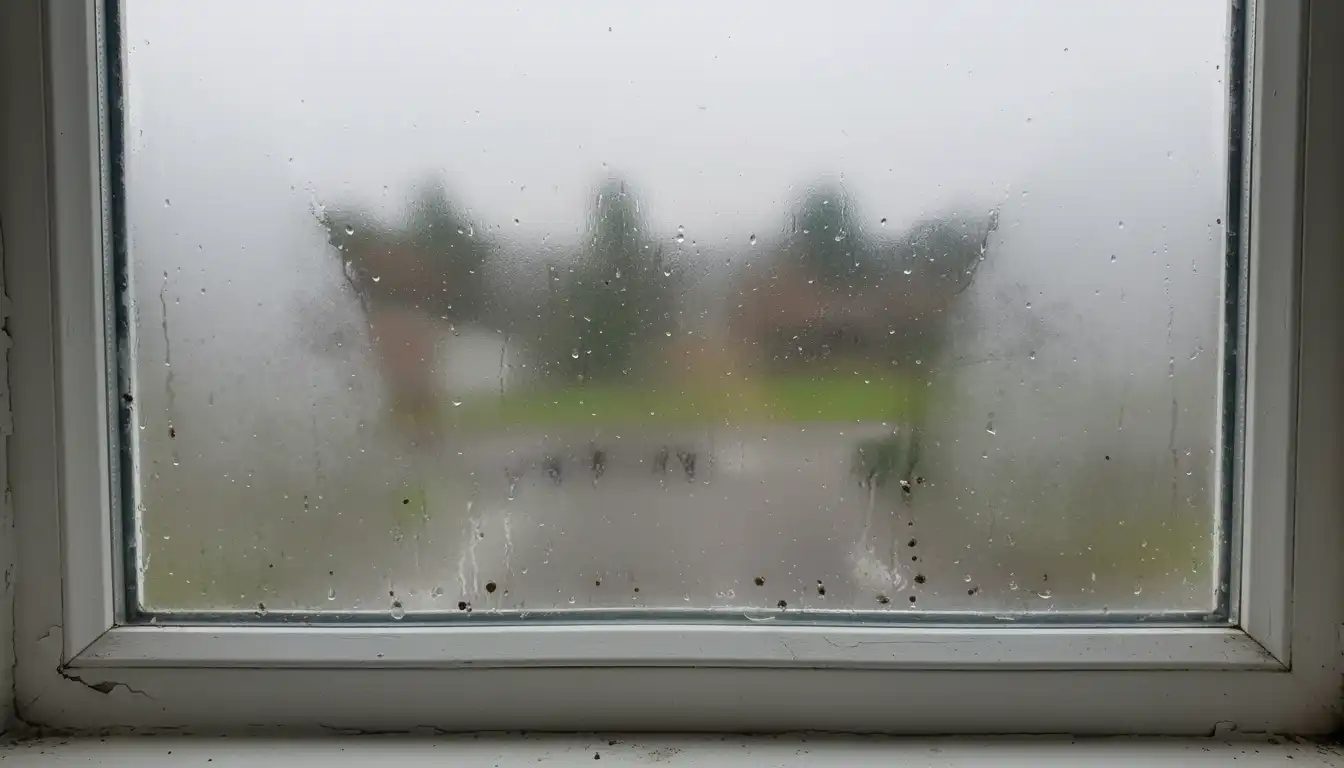

In many cases, the haze is a result of outgassing from window manufacturing materials or leftover residue from the production process. However, if the cloudiness is located between the panes of glass, it points to a more serious issue: seal failure. It’s crucial to distinguish between these two very different problems.

Identifying the Cause: Surface Film vs. Seal Failure

Before attempting any cleaning, determine the location of the haze. A temporary surface film will be on the interior or exterior of the glass, while a failed seal traps moisture inside the insulated glass unit (IGU). A simple test can help you diagnose the problem: clean a small section of the interior and exterior of the window thoroughly.

If the haze disappears in the cleaned area, the issue is a surface contaminant that can likely be removed. If the fogging or condensation remains, it is trapped between the glass panes. This indicates a broken seal, which compromises the window’s insulating properties and typically requires a warranty claim to replace the glass unit.

A Step-by-Step Guide to Safely Cleaning Low-E 366 Glass

The delicate metallic coating on Low-E glass requires a specific cleaning approach to avoid damage. Never use abrasive cleaners, squeegees with metal parts, or razor blades, as these can permanently scratch the coating. For routine cleaning and removal of stubborn factory residues, a gentle solution is most effective.

Start with a simple mixture of one part white vinegar to ten parts water. Apply the solution generously with a spray bottle and wipe with a clean, lint-free microfiber cloth. For tougher oily residues, you can use a small amount of isopropyl alcohol on a soft cloth, followed by the vinegar solution rinse, ensuring you don’t leave a film behind.

Beyond the Haze: Exploring Tints, Distortions, and Other Concerns

While haze is a common complaint, other visual imperfections can also cause concern for homeowners with Low-E 366 glass. These issues often stem from the fundamental properties of multi-coated, energy-efficient glass. Understanding the science behind what you’re seeing can help clarify whether you have a genuine defect or are observing a normal characteristic of the technology.

The triple-layer silver oxide coating that gives Low-E 366 its superior performance also interacts with light in complex ways. This can result in subtle visual effects that differ from standard clear glass, leading to questions about color accuracy and visual clarity.

The “Green Tint” Phenomenon: Feature or Flaw?

Many homeowners notice a slight green hue when looking through their Low-E 366 windows, especially from an exterior vantage point or against a white background like blinds. This is not a defect but an inherent characteristic of the triple-silver coating designed to reflect infrared heat while allowing visible light to pass through. The specific angle of the light and the time of day can make this hue more or less apparent.

This subtle tint can influence how interior paint colors are perceived. It’s a good practice to view paint samples next to your window at different times of the day before committing to a color. For instance, a color like Sherwin-Williams Wedgewood Gray might show different undertones when viewed through the specialized glass.

Understanding Visual Distortion and Reflection

In some instances, homeowners may notice minor distortions or a “roller wave” effect, particularly in tempered glass. This happens during the manufacturing process when the glass is heat-treated and passes over rollers. While industry standards limit the acceptable level of distortion, it is often an unavoidable byproduct of creating stronger safety glass.

Additionally, the multiple layers within an insulated glass unit can create a faint double reflection, especially at night when interior lights are on. This is a normal physical property of multi-pane windows and not indicative of a fault. However, if the glass appears significantly warped or distorted, it could be a sign of seal failure causing the panes to bow inward.

Thermal Stress Cracks: A Rare but Serious Issue

A more serious but less common problem is thermal stress cracking. These cracks occur when there is a significant temperature difference between the center of the glass and its edges. Low-E coatings, by design, affect how heat is absorbed and reflected, which can sometimes contribute to this stress, especially on large panes with direct sun exposure followed by shade.

A thermal crack typically starts perpendicular to the edge of the glass and can meander across the pane. Unlike impact cracks, there is no central point of damage. If you suspect a thermal stress crack, document it with photos and contact your window manufacturer immediately, as this is often covered under warranty.

Diagnosing Your Low-E 366 Window Issues

Navigating window problems can be confusing. To help homeowners identify the likely cause of their concerns, the table below outlines common symptoms, their probable causes, and the recommended course of action. This diagnostic approach empowers you to take the right steps, whether it’s a simple cleaning task or a call to a professional.

Proper identification is key to a swift resolution. Misdiagnosing a failed seal as a simple cleaning issue, or vice versa, can lead to wasted time and frustration. Use this guide to make an informed assessment of your window’s condition.

| Symptom | Likely Cause | Recommended Action |

|---|---|---|

| Cloudy or hazy film on the glass surface | Manufacturing residue, outgassing, or construction dust | Clean the glass using a 1:10 vinegar-to-water solution and a microfiber cloth. |

| Condensation or fog between the glass panes | Seal failure of the insulated glass unit (IGU) | Contact the manufacturer for a warranty claim. Do not attempt to repair. |

| A subtle green, blue, or bronze tint | Normal characteristic of the Low-E coating | No action needed. This is an inherent property of the glass. |

| Wavy or distorted reflections (“funhouse effect”) | Inherent distortion from glass tempering or IGU pressure changes | Monitor the issue. If it worsens or is severe, consult the installer. |

| A single crack originating from the edge of the glass | Thermal stress fracture | Document with photos and contact the manufacturer for a warranty claim. |

| Visible moisture damage or drafts around the frame | Installation issue or advanced seal failure | Contact a professional window installer for an inspection. |

Myths vs. Reality: What Low-E 366 Does and Doesn’t Do

High-performance products often attract myths and misconceptions, and Low-E 366 glass is no exception. It is important for homeowners to distinguish between the actual limitations and characteristics of the technology and unfounded fears. Addressing these myths helps set realistic expectations for window performance.

From concerns about houseplants to performance in cold climates, many common worries are based on a misunderstanding of how Low-E coatings work. These coatings are spectrally selective, meaning they filter different wavelengths of light to optimize energy efficiency without creating adverse effects indoors.

Myth: Low-E 366 Glass Will Harm Houseplants

A common concern is that by blocking UV and infrared light, Low-E 366 glass will starve houseplants of the light they need for photosynthesis. In reality, plants primarily use the visible light spectrum to grow, which these windows are designed to transmit effectively. While they block up to 95% of damaging UV rays, the reduction in visible light is minimal.

In fact, the technology can benefit many plants by protecting them from intense solar heat and preventing scorching. The stable indoor temperatures created by Low-E glass can also provide a healthier growing environment. Most common houseplants will thrive behind Low-E 366 glass.

Myth: Low-E 366 is Only for Hot Climates

Because of its excellent solar heat blocking capabilities, many assume Low-E 366 is only suitable for warm southern climates. However, its value extends to colder regions as well. The same coating that reflects unwanted solar heat in the summer also reflects your home’s radiant heat back into the room during the winter.

This dual-action performance significantly reduces heat loss, keeping your home warmer and lowering heating bills. The superior insulating properties of Low-E 366 make it a versatile, year-round solution for nearly any climate, providing comfort and energy savings in both summer and winter.

Proactive Care for Long-Lasting Clarity and Performance

To ensure your Low-E 366 windows perform optimally for years to come, a proactive approach to maintenance is essential. Proper care not only preserves the aesthetic clarity of the glass but also protects the entire window unit, including the frame and seals, from premature failure. Simple, regular checks can prevent small issues from becoming costly problems.

Seasonal maintenance is a key part of homeownership. Just as you would prepare outdoor equipment for changing weather, such as ensuring you have the correct John Deere snowblower gearbox oil for winter, your windows benefit from seasonal attention. This routine care helps you spot potential issues early.

The Right Way to Maintain Your Windows

Regularly inspect your window seals for any signs of cracking, peeling, or brittleness. A compromised seal is the primary cause of IGU failure and can also create entry points for moisture and insects. Spotting a damaged seal early can sometimes lead to a simpler repair rather than a full glass replacement and prevent secondary issues, such as discovering dead ants in your Terro trap near the window sill.

Keep the window tracks and weep holes clean and free of debris. Clogged weep holes can trap water within the frame, leading to damage over time and potentially compromising the integrity of the window seal. A soft brush or a vacuum cleaner attachment can easily clear these channels.

Conclusion: A Smart Investment Despite Minor Quirks

Low-E 366 windows represent a significant advancement in residential energy efficiency, offering substantial savings and enhanced comfort. While potential issues like temporary haze, a slight green tint, and rare instances of thermal stress can be concerning, they are often either manageable characteristics of the technology or warrantable manufacturing defects.

By understanding the difference between a true problem and a normal quirk, homeowners can confidently address any concerns that arise. With proper cleaning, routine maintenance, and an awareness of when to contact a professional, your Low-E 366 windows will remain a valuable, high-performing asset for your home for decades to come.