Loading a Snowblower in a Truck Bed? Stop! Read This First

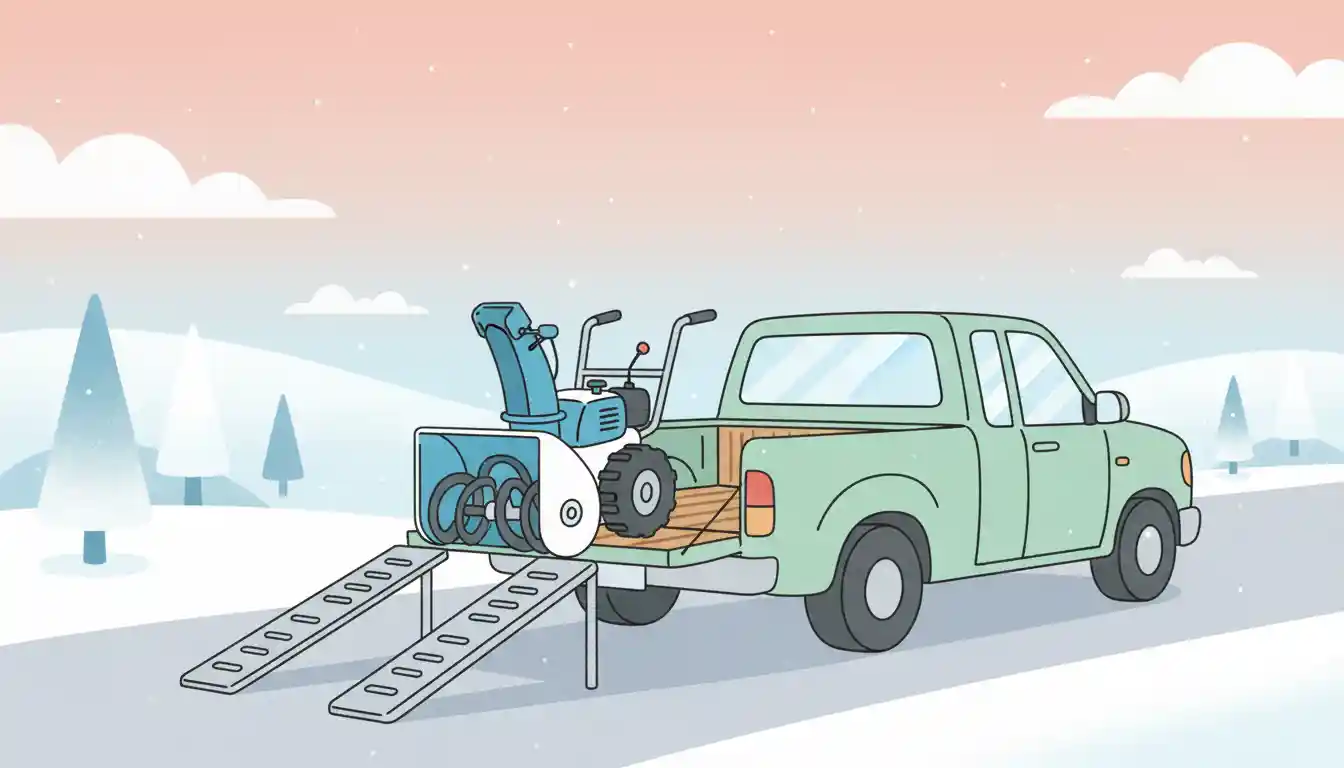

You have the snowblower. You have the truck. The problem lies in bridging the vertical gap between the ground and your truck bed. It’s a task that seems simple until you’re staring at a 250-pound machine and a tailgate that’s three feet in the air.

Wrestling a heavy, awkwardly balanced snowblower into a pickup truck is more than just a hassle; it’s a significant risk. One slip can lead to a damaged machine, a dented truck, or worse, a serious personal injury. The combination of weight, an awkward center of gravity, and often slick winter conditions creates a recipe for disaster if not approached with the right knowledge and equipment.

This guide provides a comprehensive, step-by-step framework to solve this exact problem. We will explore the safest methods, the essential gear you need, and the critical mistakes you must avoid. Following these procedures will ensure you can transport your snowblower safely and confidently, protecting both yourself and your valuable equipment.

You'll Learn About

Before You Begin: The Critical Preparation Stage

Success and safety begin long before the snowblower touches the ramp. Proper preparation is not just a preliminary step; it’s the most important part of the entire process. Rushing this stage is how accidents happen.

Taking a few extra minutes to assess your situation, prepare your equipment, and clear your workspace can mean the difference between a smooth operation and a costly mistake. Think of it as the foundation of the entire task—if it’s weak, the whole process is compromised.

The Pre-Load Safety Checklist

Before any lifting or moving occurs, a systematic safety check is non-negotiable. Go through each item on this list to ensure your environment and equipment are ready for the task ahead. This simple habit dramatically reduces the potential for unexpected problems.

| Item to Check | Action Required | Reasoning |

|---|---|---|

| Loading Area | Clear of snow, ice, tools, and debris. Ensure the ground is level and firm. | A clean, level surface prevents slips, trips, and instability of the truck or ramps. |

| Truck & Tailgate | Park on level ground, set the parking brake, and inspect the tailgate and support cables for damage. | An unstable truck can roll. Damaged tailgate cables could fail under the combined weight of the snowblower and operator. |

| Loading Ramps | Inspect for cracks, bends, or damage. Confirm weight capacity exceeds the snowblower’s weight. | Structural failure of a ramp during loading is extremely dangerous and can cause the equipment to fall. |

| Snowblower | Check tire pressure. If possible, run the fuel tank low or use the fuel shut-off valve. | Properly inflated tires make rolling easier. Minimizing fuel reduces spill risk if the machine tips. |

| Personal Gear | Wear gloves with good grip and sturdy, non-slip footwear. | Proper gear ensures a firm grip on the machine and stable footing on the ground and ramps. |

Choosing the Right Equipment

Using improper or underrated equipment is a common and dangerous mistake. Your gear must be rated for the job. Makeshift solutions like wooden planks are notoriously unreliable and prone to breaking or slipping.

Invest in a quality set of loading ramps. Look for ramps with a weight capacity that comfortably exceeds your snowblower’s weight. Arched ramps are preferable to straight ones, as they help prevent the snowblower’s housing from scraping or “bottoming out” at the top of the incline. Also, ensure the ramp surface has a high-traction design, like punch plates or aggressive grating, to prevent tires from slipping, especially in wet conditions.

For securing the load, use heavy-duty ratchet straps, not cheap ropes or bungee cords. Ratchet straps allow you to apply significant tension, ensuring the machine cannot shift during transport. Cam buckle straps are acceptable for lighter loads but may not provide enough holding force for a heavy snowblower.

Preparing the Snowblower and Truck

First, address the fuel situation. If your snowblower has a fuel shut-off valve, use it. This prevents fuel from sloshing into the carburetor and engine, which can cause starting issues later. If you don’t have a shut-off, try to perform the move when the fuel tank is nearly empty to minimize spill risk.

Position your truck on the most level ground available and engage the parking brake firmly. A clean truck bed is a safe truck bed; remove any tools, ice, or debris that could interfere with positioning the snowblower. Proper maintenance of your vehicle’s condition is always important, just as good surface preparation is critical in home projects, where people often ask if they should use TSP before or after sanding for professional results.

The Gold Standard: Loading a Snowblower with Ramps

Using a proper set of loading ramps is by far the safest and most efficient method for getting a heavy snowblower into a truck bed. This approach leverages mechanical advantage to do the heavy lifting for you, but it requires a strict adherence to procedure to remain safe.

Step 1: Secure the Ramps

This is the most critical step in the entire process. Never place ramps on the tailgate without securing them to the truck. The force of the snowblower moving up the incline can cause the base of the ramps to “kick out,” leading to a catastrophic failure.

Your ramps should come with safety straps. Loop these straps around a secure part of the ramp and connect them to a solid anchor point on your truck, such as the receiver hitch or a frame member. Cinch the straps tight so there is no slack, ensuring the ramps are pulled firmly against the tailgate and cannot slide backward.

Step 2: Powering Up the Incline (The Right Way)

If you have a self-propelled snowblower, you can use its own power to assist with loading. Start the engine and position the snowblower at the base of the secured ramps. It’s crucial that you control the machine from the side, not from directly behind it.

Engage the drive at the slowest possible speed and walk alongside it, guiding it up the ramps. Maintain a firm grip and be prepared to disengage the drive immediately if you lose control. Never stand directly between the handlebars and walk up the ramp behind the machine. If the snowblower were to lose traction and roll backward, you would have no escape path.

The Manual Push Method (If Not Self-Propelled)

Loading a non-self-propelled or non-running snowblower requires at least two people. Do not attempt this alone. One person should be at the bottom, providing the primary pushing force, while the second person is on the side or in the truck bed, guiding the machine and helping to pull it forward once it’s within reach.

Communicate clearly throughout the process. The person pushing should focus on using their leg muscles, keeping their back straight to avoid strain. A coordinated “1, 2, 3, push” can help synchronize your efforts for moving the machine up the incline smoothly.

No Ramps? No Problem: Alternative Loading Methods

While ramps are the ideal solution, situations may arise where they are not available. In these cases, you can still load a snowblower, but the risk is higher and requires even more caution and planning.

The Two-Person Lift: Brute Force with a Brain

This method should be a last resort and must never be attempted alone. It requires two people of adequate physical strength who can communicate clearly. Before lifting, have a plan. Identify solid, non-plastic lifting points on the snowblower’s frame and engine housing.

The safest approach is to lift one end at a time. Both people should position themselves on opposite sides of the machine. On a coordinated count, lift the heavy engine end of the snowblower and rest it securely on the edge of the open tailgate. Then, reposition to the back and lift the handle end, sliding the entire unit forward into the truck bed.

Using a Hill or Embankment

This is a clever and much safer alternative to manual lifting if your landscape allows for it. Find a steep driveway, a small hill, or a landscaping embankment that you can back your truck up to. The goal is to position the truck’s tailgate so it is nearly level with the higher ground.

By eliminating the height difference, you can simply roll the snowblower directly into the truck bed without any dangerous inclines or heavy lifting. This highly effective method is often overlooked but can turn a dangerous task into a simple one.

Mission Accomplished: How to Secure a Snowblower for Transport

Getting the snowblower into the truck is only half the battle. Now you must ensure it stays put. An unsecured, 250-pound object can become a dangerous projectile in a sudden stop or turn, posing a risk to your vehicle and other drivers.

The “Four-Point” Lockdown

The best practice for securing heavy equipment is to use four separate ratchet straps to create opposing forces. Push the snowblower to the very front of the truck bed, with its housing firmly against the front wall. This prevents it from sliding forward under braking.

Attach one strap to each corner of the snowblower’s frame, connecting them to the four corner anchor points in your truck bed. Tighten the front two straps pulling forward and outward, and the back two straps pulling backward and outward. This creates a rigid, unmovable lockdown that prevents shifting in any direction. When securing equipment, a perfect fit is essential, much like when using a universal window mull kit to ensure a window is sealed and stable.

Final Checks Before You Drive

Once the straps are tight, give the snowblower a firm push from all sides. It should feel like a solid part of the truck and not rock, shift, or slide in any way. Double-check that all ratchet mechanisms are locked. After driving a short distance, it’s wise to pull over and check the straps again to ensure nothing has loosened.

Unloading: The Process in Reverse

Unloading follows the same principles as loading, but in reverse. Gravity is now working against you, which makes controlling the snowblower’s descent even more critical. Whether you’re using ramps or have a helper, the process must be slow and deliberate.

If using ramps with a self-propelled machine, use the engine and drive system to “brake” the descent, letting it out slowly in the lowest gear. If pushing it down manually with a helper, one person must be in the bed guiding it onto the ramps while the other is at the bottom, ready to control and stop its momentum as it comes down.

Common Mistakes to Avoid at All Costs

Many loading accidents are caused by a few common, preventable errors. Being aware of these pitfalls is key to ensuring a safe operation every single time.

- Using Wooden Planks: Never use untreated lumber as ramps. They can be slippery, can’t handle the weight, and can easily break.

- Not Securing Ramps: This is the most frequent cause of catastrophic failure. Always use safety straps to tie the ramps to the truck.

- Standing Behind the Machine: Always position yourself to the side when moving a snowblower up or down a ramp to maintain an escape path.

- Lifting Alone: A two-stage snowblower is too heavy and awkward for one person to lift safely. Always get help.

- Improper Tie-Downs: Do not use rope or bungee cords. Only high-tension ratchet straps are suitable for securing heavy machinery.

Conclusion: Load Like a Pro, Drive with Confidence

Loading a snowblower in a truck bed doesn’t have to be a dangerous or intimidating task. By prioritizing preparation, using the correct equipment, and following a methodical, safety-first procedure, you can eliminate the risks and perform the job with professional efficiency.

Remember the key principles: secure your ramps, control the machine’s movement at all times, and lock it down tightly for transport. This attention to detail protects your equipment, your truck, and most importantly, yourself. Properly transporting your snowblower is just one component of good seasonal readiness. Soon you’ll be tackling other tasks to prepare your home for the cold, like figuring out how to defrost a freezer without getting water everywhere.