Kohler Pulse Fuel Pump Problems? Here’s Your Ultimate Fix Guide

That familiar sputtering sound. The engine that starts strong, only to die out minutes later. These are the frustrating calling cards of a lawn tractor or mower that just won’t run right. While many things can go wrong, one of the most common and misunderstood culprits is the Kohler pulse fuel pump.

This small but vital component is the heart of your engine’s fuel system. When it fails, your powerful machine becomes nothing more than a heavy garden ornament. This comprehensive guide will walk you through diagnosing, understanding, and solving your Kohler pulse fuel pump problems for good.

You'll Learn About

What is a Pulse Fuel Pump and Why Does it Fail?

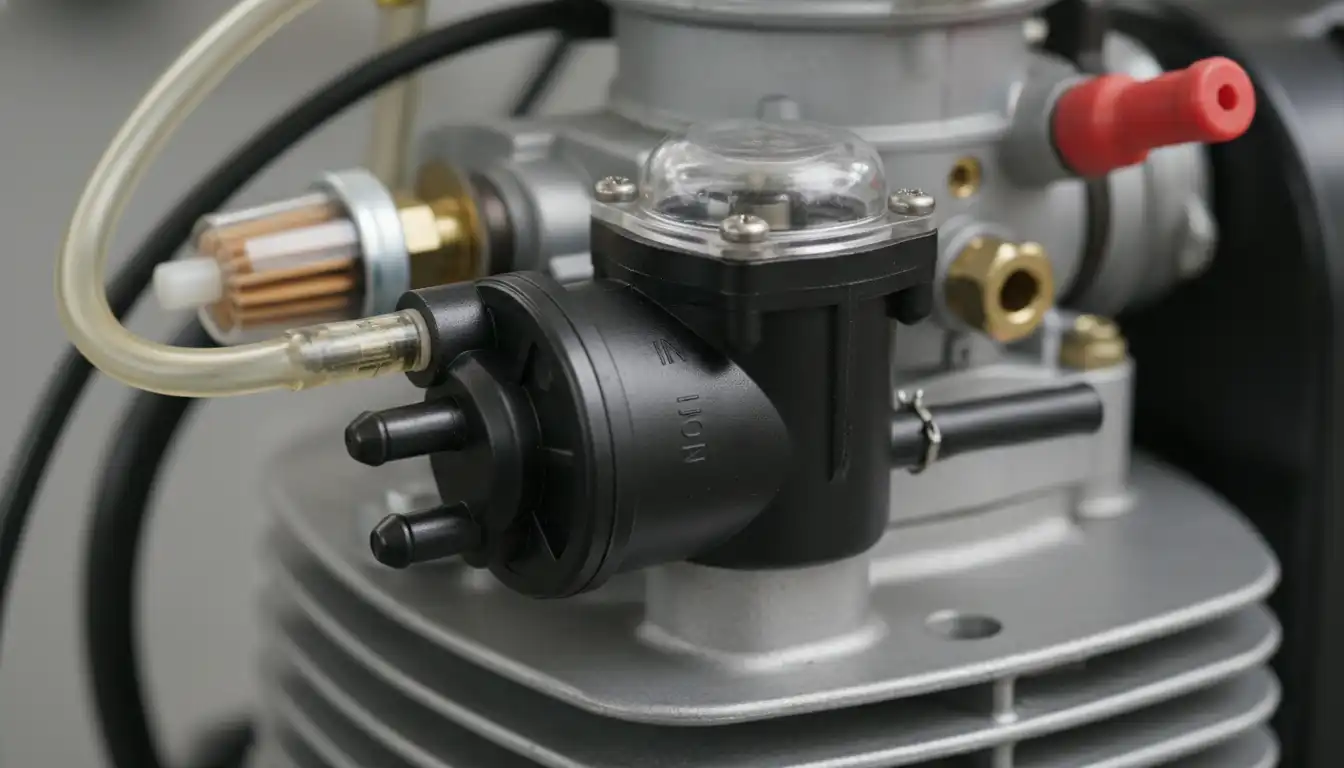

Unlike the electric fuel pumps in your car, most small engines, including those from Kohler, use a clever mechanical system. The pulse fuel pump is a vacuum-operated diaphragm pump. It uses the pressure fluctuations (pulses) from the engine’s crankcase to create a pumping action.

This simple design is generally reliable, but it has key vulnerabilities. Understanding these weak points is the first step toward a lasting repair. The system relies on a delicate balance of pressure and suction to deliver a steady stream of gasoline to the carburetor.

The Critical Role of the Diaphragm

Inside the pump is a flexible rubber diaphragm. As the piston moves up and down in the engine, it changes the pressure in the crankcase. This changing pressure is channeled through a hose to the fuel pump, causing the diaphragm to flex back and forth, sucking fuel in from the tank and pushing it out to the carburetor.

Over time, this diaphragm is the primary point of failure. Modern gasoline, especially fuels containing ethanol, can cause the rubber to become brittle, stiff, or even develop microscopic tears. When this happens, the pump loses its ability to create adequate suction and pressure.

Crankcase Pulse: The Engine’s Heartbeat

The entire system depends on a clean, strong “pulse” from the engine’s crankcase. This pulse is delivered via a rubber or plastic hose. If this hose is cracked, loose, or clogged, the signal to the pump becomes weak or non-existent.

Without this signal, the diaphragm won’t move, and no fuel will be pumped. It’s like trying to listen to a radio with a broken antenna; the signal simply can’t get through. This is a frequently overlooked cause of fuel delivery issues.

Telltale Signs: Recognizing a Failing Kohler Fuel Pump

Fuel pump problems can often mimic other engine issues, like a dirty carburetor or a clogged filter. However, there are specific symptoms that point directly to the pulse pump. Paying close attention to how your engine behaves can save you hours of guesswork.

One of the most common signs is an engine that seems to be running out of gas, even with a full tank. If your engine starts easily but then sputters and dies after a few minutes of running, especially under load (like when you engage the mower blades), the fuel pump is a prime suspect. This is a classic symptom of an engine that is slowly being starved of fuel.

Engine Surging and Stalling

Does your engine’s RPM fluctuate wildly without you touching the throttle? This surging is often caused by an inconsistent fuel supply. The pump may be delivering just enough fuel to keep the engine alive, but not enough for smooth, stable operation.

Eventually, this surging will lead to stalling. The engine might run fine on level ground but die when you try to go up a slight incline. This is because going uphill places a greater load on the engine, demanding more fuel than the weakened pump can deliver.

Difficulty Starting Without Priming

A healthy fuel pump should pull fuel from the tank and fill the carburetor bowl within a few cranks of the engine. If you find that your engine refuses to start unless you manually add fuel or use starting fluid, it’s a strong indicator that the pump isn’t doing its job.

This initial failure to prime is a direct result of a weak or failed diaphragm that can’t create the initial suction needed to lift the fuel from the tank. If you’re experiencing broad fuel delivery issues, it’s worth understanding the complete system; a Kohler engine starving for fuel can have several causes, and the pump is a major one.

The Ultimate Diagnostic and Troubleshooting Guide

Before you spend money on a new pump, it’s crucial to confirm the old one is truly the problem. This diagnostic process is straightforward and requires only basic tools. Following these steps methodically will pinpoint the exact point of failure.

We’ll cover visual inspections, hose integrity checks, and functional tests to give you a definitive answer. Don’t skip these steps; a simple cracked hose can produce the exact same symptoms as a completely failed pump.

Step 1: The Visual Inspection

Start by locating the fuel pump. It’s typically a black or gray plastic rectangular or round component mounted on the side of the engine shroud. You will see three connection points: a fuel inlet from the tank, a fuel outlet to the carburetor, and the all-important pulse line from the engine crankcase.

Look for obvious signs of damage. Are there cracks in the plastic housing? Is there evidence of fuel leaking from the seams? A pump that is wet with gasoline is a clear sign that the internal diaphragm has ruptured, and the pump must be replaced.

Step 2: Inspecting the Fuel and Pulse Lines

Carefully examine every inch of the three hoses connected to the pump. These rubber or plastic lines can become brittle and crack with age and heat exposure. A tiny, almost invisible crack in the pulse line is enough to kill the vacuum signal.

Disconnect the lines from the pump one at a time and inspect the ends. Check for softness, mushiness, or splits. Squeeze the lines along their entire length to feel for hard, brittle sections. Pay extra close attention to the pulse line, as its integrity is paramount for the pump’s operation.

Step 3: The Pulse Test

This is the definitive test to see if the engine is providing the signal the pump needs. Disconnect the pulse line from the fuel pump itself. Place your thumb over the end of the hose.

Have a helper crank the engine (ensure the spark plug is disconnected for safety to prevent accidental starting). You should feel a distinct puffing or a noticeable suction and pressure against your thumb. If you feel nothing, the problem lies with the pulse line or a blockage at the crankcase fitting, not the pump.

Step 4: The Fuel Flow Test

Now, let’s test the pump’s output. Disconnect the fuel line from the carburetor’s inlet and place the end into a clean glass jar or container. With the fuel line from the tank and the pulse line still connected to the pump, crank the engine.

You should see healthy, strong spurts of fuel coming out of the line into the jar. If you get a weak dribble or no fuel at all, and you’ve already confirmed the pulse signal is strong in the previous step, you have now definitively diagnosed a failed fuel pump.

Comprehensive Troubleshooting Table

Use this table to quickly cross-reference symptoms with their likely causes and the recommended actions. This can help streamline your diagnostic process and get you to the solution faster.

| Symptom | Most Likely Cause | Solution |

|---|---|---|

| Engine starts, then dies after a few minutes. | Weak fuel pump diaphragm cannot keep up with demand. | Perform fuel flow test. Replace fuel pump if flow is weak. |

| Engine surges or hunts for RPM. | Inconsistent fuel delivery from a failing pump. | Inspect all fuel lines for cracks or blockages. Test pump output. |

| Engine won’t start without starting fluid. | Pump has failed and is not priming the carburetor. | Confirm pulse signal is present. Replace fuel pump if signal is good but no fuel flows. |

| Engine dies when going uphill or under load. | Pump output is insufficient for high-demand situations. | Replace the fuel pump and the fuel filter at the same time. |

| Visible fuel leak around the pump housing. | Ruptured internal diaphragm. | Immediate replacement required. Do not run the engine. |

| No fuel flow during output test. | Cracked pulse line or completely failed pump. | Perform the pulse test on the pulse line itself. If pulse is good, replace pump. If not, replace pulse line. |

Replacing Your Kohler Pulse Fuel Pump: A Step-by-Step Guide

Once you’ve confirmed the pump is the culprit, the replacement process is very straightforward. It typically takes less than 30 minutes and requires only basic hand tools like pliers and a screwdriver or nut driver. This is a repair well within the skill level of most homeowners.

Always work in a well-ventilated area away from any ignition sources. Gasoline is highly flammable. Having some rags handy to catch any minor fuel spills is also a good idea.

Step 1: Procure the Correct Part

Before you begin, you need the right replacement pump. You can find the engine model number on a sticker on the engine shroud. Use this number to look up the exact fuel pump part number for your Kohler engine. Using a genuine Kohler part or a high-quality aftermarket equivalent is recommended for longevity.

Step 2: Disconnect the Lines

It’s wise to clamp off the fuel line coming from the tank to prevent gasoline from draining out. A pair of small vise-grips or a dedicated fuel line clamp works well. Now, using pliers, carefully squeeze the hose clamps and slide them down the hoses.

Gently twist and pull each of the three hoses off the old fuel pump. Take note of which hose goes to which port. The ports are often marked with arrows indicating fuel flow direction (IN and OUT), and the third is for the pulse line.

Step 3: Unbolt the Old Pump

The fuel pump is typically held onto the engine shroud or a bracket with two small bolts or screws. Use the appropriate nut driver or screwdriver to remove them. The old pump will now be free. Take this opportunity to clean the mounting area with a rag.

Step 4: Install the New Pump

Position the new pump in the same orientation as the old one and secure it with the mounting bolts. Do not overtighten them, as this can crack the plastic housing. Just make them snug.

Now, reconnect the three hoses to their correct ports on the new pump. Slide the hose clamps back into position to secure them. Make sure the connections are tight to prevent leaks. You can now remove the clamp from the main fuel line.

Preventative Maintenance: The Secret to a Long-Lasting Fuel System

Replacing the pump solves the immediate problem, but adopting a few preventative habits can keep you from repeating the process in a few years. The health of your entire fuel system is interconnected. A well-maintained machine is essential for any homeowner dedicated to their property.

Keeping your lawn equipment in top shape ensures you have more time for other tasks. This might include enriching your garden, where you might have to manage issues like the distinct blood meal smell from organic fertilizers. A reliable mower makes all yard work easier.

Use Fresh, Stabilized Fuel

The single most important thing you can do is use fresh fuel (less than 30 days old) treated with a quality fuel stabilizer. Stabilizers prevent ethanol from separating from the gasoline and absorbing water, a process called phase separation. This ethanol-water mixture is highly corrosive and destructive to rubber components like the fuel pump diaphragm.

Using non-ethanol gasoline, if available in your area, is an even better choice for preserving the life of small engine fuel systems. It provides a cleaner burn and eliminates the risk of ethanol-related damage entirely.

Regularly Replace Your Fuel Filter

Your fuel filter is the last line of defense, preventing tiny particles of dirt and debris from reaching the fuel pump and carburetor. A clogged filter forces the pump to work much harder to pull fuel from the tank, leading to premature failure.

Replacing the fuel filter should be part of your annual spring tune-up. It’s an inexpensive part that provides significant protection for more costly components down the line. Maintaining every aspect of your home, from the lawnmower engine to the pool surface, is key; for instance, understanding River Rok pool finish reviews can be just as important for a homeowner as understanding engine repair.

The Unspoken Role of Crankcase Health

Here’s something few guides mention: the health of the engine’s crankcase directly impacts the fuel pump. The pulse signal originates here. If your engine has excessive “blow-by” (combustion gases leaking past the piston rings), it can introduce oily residue into the pulse line.

This oily mist can slowly coat the inside of the pulse line and the fuel pump diaphragm, impeding their function. While addressing blow-by is a more advanced repair, being aware of it is important. If you find an oily film inside your pulse line during inspection, it may be a sign of deeper engine wear that needs attention.

By understanding not just the “how” but the “why” of Kohler pulse fuel pump problems, you are empowered to make a lasting repair. A methodical approach to diagnosis and a commitment to preventative maintenance will ensure your equipment starts reliably and runs strong season after season.