Kohler Engine Starving for Fuel? Your Ultimate 10-Step Fix

There’s nothing more frustrating than being halfway through a lawn mowing session or relying on your generator during a power outage, only to have the engine sputter, surge, and die. A Kohler engine starving for fuel is a common headache for homeowners, turning a simple task into a major diagnostic challenge. This sudden loss of power is not just an inconvenience; it’s a clear signal that your engine’s fuel system is compromised.

When an engine doesn’t get the consistent supply of fuel it needs, it can’t run efficiently, leading to sputtering, stalling, and a significant drop in performance. This guide will walk you through the entire troubleshooting process, from identifying the subtle symptoms to implementing a step-by-step repair plan. You’ll learn to diagnose the problem like a pro and restore your equipment to its reliable, powerful state.

You'll Learn About

Understanding the Symptoms: Is Your Kohler Engine Truly Starving?

Before diving into repairs, it’s crucial to confirm that fuel starvation is the real issue. The symptoms can sometimes mimic other engine problems, but a few key signs point directly to a lack of fuel. Recognizing these signals is the first step toward a successful repair.

The most common symptom is engine surging or hunting, where the RPMs fluctuate up and down without you touching the throttle. You’ll also likely experience a noticeable loss of power under load; for instance, a mower might run fine on the driveway but bog down and stall in thick grass. Other classic signs include difficulty starting, frequent stalling, and an engine that runs only when the choke is partially engaged.

The Telltale Signs of Fuel Starvation

Pay close attention to how your engine behaves. An engine starving for fuel will often start and idle for a moment before sputtering and dying. This happens because the small amount of fuel in the carburetor bowl is used up, and the compromised fuel system can’t replenish it fast enough to keep the engine running smoothly.

The Root Causes: Why Your Engine is Thirsty for Fuel

A Kohler engine’s fuel system is a chain of components working together, and a problem in any single link can lead to fuel starvation. The issue can range from something incredibly simple to a more complex internal blockage. Systematically checking each component is the key to an accurate diagnosis.

The Usual Suspects: Simple Fixes First

Always start with the easiest and most obvious potential problems. Check the fuel tank to ensure it isn’t empty—it sounds basic, but it happens. More importantly, ensure you’re using fresh, clean gasoline. Fuel that is more than 30 days old, especially gasoline containing ethanol, can degrade and form gummy deposits that clog the system.

Another simple but often-overlooked culprit is a clogged fuel cap vent. The fuel cap has a tiny hole to let air in as fuel is drawn out, equalizing the pressure. If this vent is blocked by dirt or debris, it creates a vacuum in the tank that can prevent fuel from flowing freely to the engine.

The Fuel Filter: Your Engine’s First Line of Defense

The fuel filter is designed to trap dirt, rust, and other contaminants before they can reach the sensitive components of the carburetor. Over time, this filter can become so clogged that it severely restricts fuel flow. A dirty fuel filter is one of the most common causes of fuel starvation and, thankfully, one of the easiest and cheapest parts to replace.

You can often see debris inside the filter housing if it’s clear plastic. Even if it looks clean, it can be internally clogged. As a rule of thumb, replacing the fuel filter is a smart, preventative step in any fuel system diagnosis.

The Fuel Pump: Heart of the Fuel System

Many larger Kohler engines use a fuel pump to move fuel from the tank to the carburetor, especially when the tank is located lower than the engine. These are typically vacuum or pulse-operated pumps with an internal rubber diaphragm. Over time, this diaphragm can crack, stiffen, or develop pinholes, leading to a weak or non-existent pumping action.

A failing fuel pump often presents as an engine that runs for a few minutes and then dies, only to restart after sitting for a while. This happens because the weak pump can’t keep up with the engine’s demand for fuel. Testing the fuel pump’s output is a critical diagnostic step.

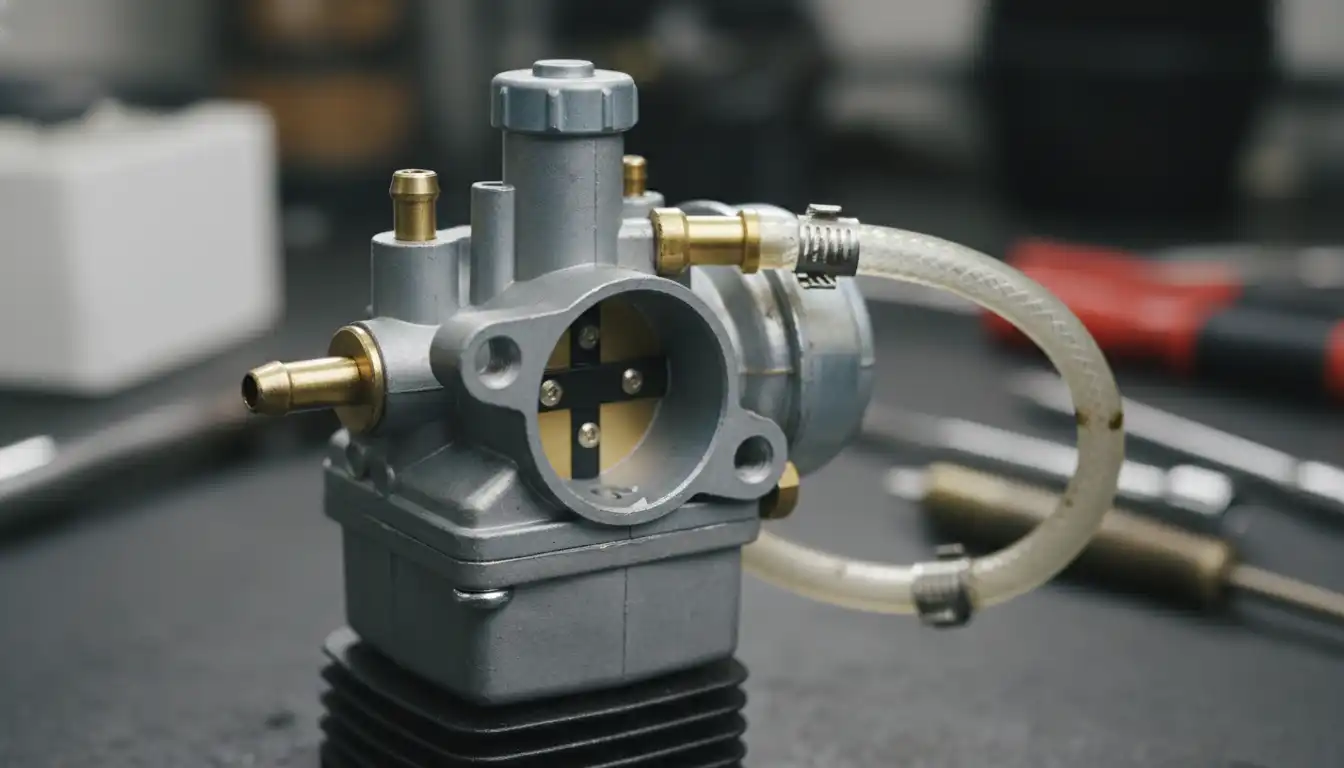

The Carburetor: Where Fuel Meets Air

The carburetor is the most complex part of the fuel system and a very common source of problems. Its job is to mix fuel and air in a precise ratio for combustion. Inside the carburetor are tiny passages and jets that can become easily clogged by the varnish and deposits left behind by old fuel.

The main jet and the idle jet are the most frequent offenders. A blockage in these tiny orifices will directly starve the engine of fuel, causing the classic symptoms of surging and stalling. Modern ethanol-blended fuels are notorious for attracting moisture and breaking down, which accelerates the process of carburetor gumming and corrosion.

Beyond the Fuel System: The Unconventional Culprits

Sometimes, what appears to be a fuel starvation issue is actually an air leak. A cracked or poorly seated intake manifold gasket can allow excess air to be sucked into the engine, creating a lean condition that perfectly mimics the symptoms of fuel starvation. The engine surges and lacks power because the air-to-fuel ratio is incorrect.

Another potential issue is a faulty anti-afterfire solenoid. This small, electrically operated plunger is located at the bottom of the carburetor bowl and controls fuel flow to the main jet. If this solenoid fails to retract when the key is turned on, it will physically block fuel from entering the main jet, effectively starving the engine.

The Ultimate 10-Step Troubleshooting and Repair Guide

Now that you understand the potential causes, it’s time for a hands-on approach. Follow these steps methodically to pinpoint and fix the source of your Kohler engine’s fuel starvation problem. Always prioritize safety: work in a well-ventilated area, disconnect the spark plug wire before working on the engine, and be cautious when handling gasoline.

Step 1: Start with the Basics (Fuel & Cap)

First, check the fuel level and ensure the gasoline is fresh. If it’s old, drain the tank and refill it with new, high-quality fuel. Next, test the fuel cap by loosening it slightly and running the engine. If the engine runs better, the vent is clogged; clean it with compressed air or replace the cap.

Step 2: Inspect the Fuel Lines

Visually trace the fuel line from the tank to the carburetor. Look for any kinks, cracks, or soft spots. Ensure all connections are tight and that the line is not pinched by any part of the engine housing.

Step 3: Replace the Fuel Filter

This is a cheap and easy step that solves a high percentage of fuel starvation issues. Pay attention to the arrow on the new filter, which indicates the direction of fuel flow—it should always point towards the carburetor.

Step 4: Test the Fuel Pump

Disconnect the fuel line from the carburetor’s inlet and place the end into a clean container. Crank the engine a few times. You should see strong, pulsing spurts of fuel coming out of the line. If you only get a weak trickle or no fuel at all, the fuel pump is likely faulty and needs to be replaced.

Step 5: The Carburetor Deep Dive: Cleaning the Jets

If the previous steps didn’t solve the problem, the carburetor is the next logical target. Remove the carburetor from the engine. Carefully detach the fuel bowl at the bottom. The main jet is the brass fitting in the center tube. Unscrew it and hold it up to a light source; you should be able to see clearly through the tiny hole in the center. If not, clean it thoroughly with carburetor cleaner and a very fine wire, like a single bristle from a wire brush. Do the same for the idle jet, which is typically a smaller jet located on the side of the carburetor.

Step 6: Checking the Anti-Afterfire Solenoid

With the carburetor removed, reconnect its wire. Turn the ignition key to the “on” position without starting the engine. You should hear a distinct “click” from the solenoid as its plunger retracts. If you hear nothing, or if the plunger doesn’t move, the solenoid is bad and must be replaced.

Step 7: Hunting for Vacuum Leaks

With the engine running, carefully spray a small amount of carburetor cleaner around the area where the carburetor mounts to the engine and around the intake manifold gaskets. If there is a vacuum leak, the engine’s RPM will change noticeably as it sucks in the flammable cleaner. If this happens, you’ll need to replace the leaking gasket.

Step 8: Consider Your Fuel Choices

To prevent future issues, consider using ethanol-free, high-octane gasoline, especially for equipment that is stored for long periods. Always add a quality fuel stabilizer to fresh gas to slow down the degradation process and keep your fuel system clean.

Step 9: Proper Storage and Maintenance

If you plan to store your equipment for more than a month, it’s best to either run the engine dry to empty the carburetor or fill the tank completely with stabilized fuel. A full tank leaves less room for air, which reduces moisture condensation.

Step 10: When to Call a Professional

If you’ve gone through all these steps and the engine still isn’t running correctly, there may be a more complex issue at play, such as incorrect valve lash or internal engine problems. At this point, it’s wise to consult a qualified small engine mechanic to avoid causing further damage.

Proactive Maintenance: Preventing Fuel Starvation Before It Starts

The best way to deal with a fuel-starved engine is to prevent it from happening in the first place. A consistent maintenance schedule is your best defense against fuel system problems. This table outlines a simple yet effective routine to keep your Kohler engine running reliably.

| Component | Action | Frequency |

|---|---|---|

| Fuel | Use Fresh, Stabilized Fuel | Every Refill |

| Fuel Filter | Replace | Annually or every 100 hours |

| Air Filter | Clean or Replace | Every 25-50 hours (or as needed) |

| Fuel Lines | Inspect for Cracks and Wear | Annually |

| Carburetor | Clean Externally | Annually |

| Fuel Tank | Check for Debris/Water | Seasonally |

The Bigger Picture: Engine Health and Home Maintenance

Maintaining your lawn and garden equipment is about more than just convenience; it’s an investment in the longevity and value of your tools. Making smart, proactive choices with your engine’s fuel system is similar to making decisions about your home’s upkeep. Just as you might wonder is it worth replacing baseboards to improve your home’s value and appearance, regular engine maintenance preserves the value and functionality of your equipment.

When it comes to parts, choosing quality matters. You might ask yourself, are hunter douglas blinds worth it for their durability and performance? The same logic applies to engine components. Using a genuine Kohler fuel filter or a high-quality carburetor kit ensures better performance and a longer lifespan than cheaper, inferior alternatives. Taking shortcuts on fundamental components, like trying to install stucco without sheathing, often leads to much bigger problems down the road; similarly, neglecting your engine’s fuel system can cause catastrophic failure.

Conclusion: Restoring Power and Peace of Mind

A Kohler engine starving for fuel can bring your work to a screeching halt, but it’s a problem that is almost always solvable with a systematic and patient approach. By starting with the simplest potential causes and working your way toward the more complex components like the carburetor, you can effectively diagnose and repair the issue yourself.

Remember that prevention is the ultimate solution. Using fresh, stabilized fuel and adhering to a regular maintenance schedule will save you countless hours of frustration. Taking control of your equipment’s health not only ensures it’s ready when you need it but also empowers you with the confidence and skills to tackle any challenge your home and garden throw your way.