John Deere L110 Transmission Problems? Your Ultimate Fix-It Guide

The John Deere L110 is a dependable workhorse for many homeowners, faithfully cutting acres of grass season after season. But when its forward momentum slows to a crawl, especially on hills, it can be incredibly frustrating. If you’re experiencing these issues, you’re likely facing one of the most common John Deere L110 transmission problems.

Many owners feel stuck, believing the only options are a costly dealer repair or a new mower. However, most L110 transmission issues are diagnosable and fixable right in your own garage. This guide will walk you through the symptoms, causes, and actionable solutions to get your mower running strong again.

You'll Learn About

Is Your L110 Transmission Failing? Key Warning Signs

Transmission problems rarely appear overnight. They usually start with subtle symptoms that worsen over time. Recognizing these early warning signs can help you address the issue before it becomes a complete failure.

Symptom 1: The Mower Slows Down, Especially on Hills

This is the most common complaint. Your L110 starts strong on flat ground, but as the transmission heats up after 15-30 minutes, it loses power. You’ll notice a significant drop in speed when trying to climb even a slight incline.

Symptom 2: A Complete Loss of Power (Won’t Move)

In more advanced stages of failure, the mower may refuse to move in forward or reverse at all. The engine will be running perfectly, but pressing the pedal does nothing. This often happens after the transmission is fully warmed up.

Symptom 3: Whining or Grinding Noises

Unusual noises from the rear of the tractor are a clear red flag. A high-pitched whine that changes with engine RPM or a grinding sound when you try to engage the drive often indicates low or contaminated fluid, or even internal damage.

Symptom 4: The Mower is Jerky or Unresponsive

If your mower’s movement is hesitant or jerky, it can point to air in the hydrostatic system or failing internal components. You might press the pedal and feel a delay before the transmission engages.

The Root Cause: Why the Tuff Torq K46 Transmission Fails

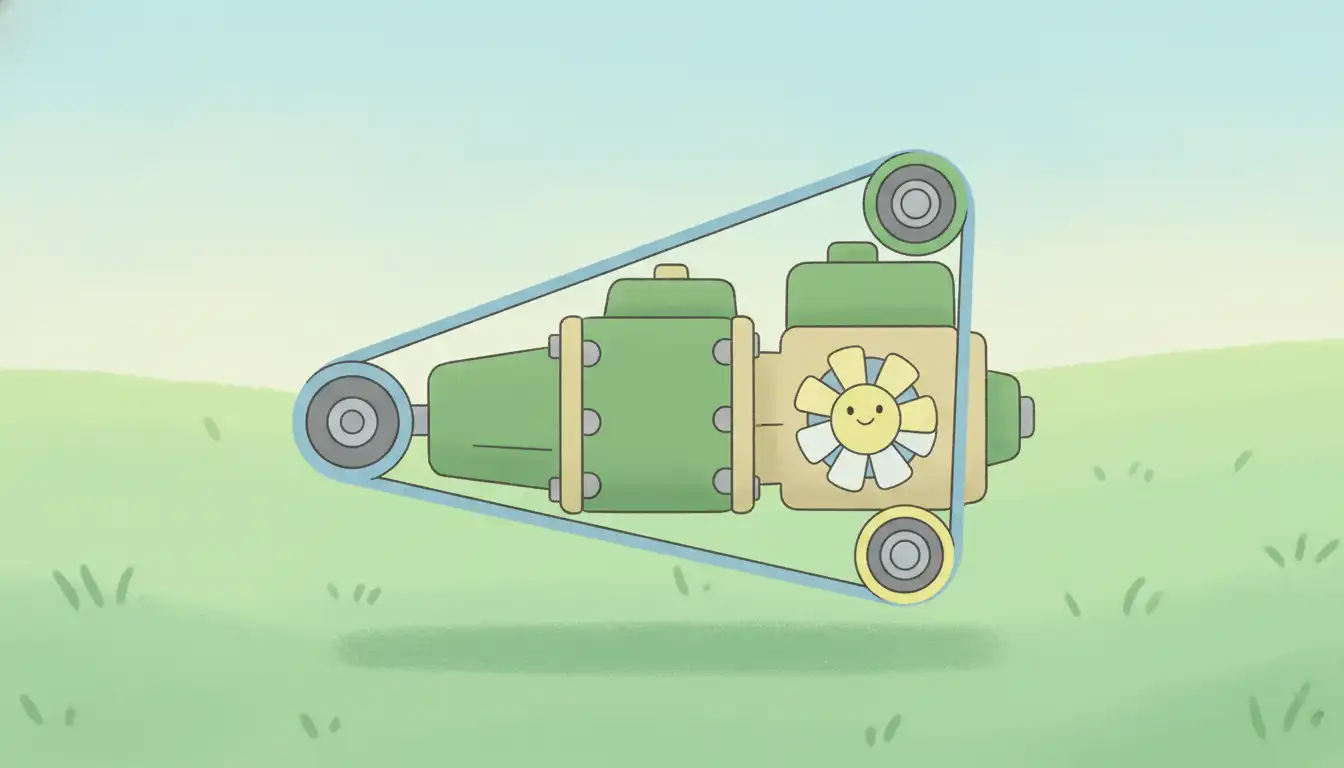

Understanding the “why” behind the failure is crucial for a lasting fix. The John Deere L110 is equipped with a Tuff Torq K46, an integrated hydrostatic transaxle. While used in many mowers, it has known vulnerabilities, especially under heavy use.

The “Non-Serviceable” Myth and Oil Breakdown

Many manufacturers, including John Deere, label the K46 as a “sealed, non-serviceable” unit. This leads owners to believe the internal fluid lasts a lifetime. In reality, the factory-installed 10W-30 conventional oil breaks down from heat and shear forces over hundreds of hours.

This degraded oil loses its viscosity and lubricating properties. As it thins out, it can no longer create the hydraulic pressure needed for the internal pump and motor to function, especially when hot. This loss of pressure is what causes your mower to lose power on hills.

Overheating: The Silent Killer

Heat is the number one enemy of any hydrostatic transmission. The K46 is cooled by a small plastic fan mounted on top of the input pulley. Over time, grass clippings, dirt, and debris pack onto the top of the transaxle, insulating it and blocking airflow from the fan. A broken or missing fan blade will also lead to rapid overheating.

Internal Wear and Tear

The K46 is designed for light-duty residential use on relatively flat lawns. Using it for heavy towing, pulling aerators, or consistently mowing steep inclines puts immense strain on the internal pump and motor. This excessive load accelerates wear, leading to internal bypassing of fluid and a permanent loss of power that an oil change alone may not fix.

Drive Belt and Pulley Issues

Sometimes, the problem isn’t inside the transmission at all. A worn, stretched, or glazed drive belt can slip on the pulleys, especially under load. This will mimic the symptoms of a failing transmission, so it’s always one of the first things you should check.

Your Step-by-Step Action Plan to Fix Your L110 Transmission

Now for the good part: the solutions. We’ll start with the simplest checks and move to the most effective repair. This structured approach can save you time, money, and frustration.

Step 1: Start with the Basics (Easy Checks)

Before diving into major surgery, rule out the simple culprits. First, ensure the freewheel lever at the back of the tractor is fully pushed in. If it’s pulled out, the transmission is disengaged, and the mower won’t move under its own power.

Next, with the mower off and the parking brake set, inspect the drive belt. Look for cracks, glazing, or excessive slack. A healthy belt is crucial for transferring power from the engine to the transmission.

Step 2: The Most Important Fix – The Transmission Oil Change

Changing the transmission fluid is the single most effective repair for a K46 that is losing power when hot. Despite being called a “sealed” unit, the oil can and absolutely should be changed. Upgrading to a high-quality full synthetic oil will dramatically improve performance and longevity.

Tuff Torq themselves now recommend a full synthetic 5W-50 motor oil as a superior replacement for the original 10W-30. The thicker viscosity of a 50-weight oil helps the worn internal parts create pressure even when hot, and the synthetic base provides far better resistance to heat breakdown. The process involves removing the transaxle from the mower, which can be time-consuming but is very manageable. During this process, you may find yourself dealing with a wheel rusted to the axle, which will require some penetrating oil and patience to remove.

Step 3: When an Oil Change Isn’t Enough (Advanced Options)

If a synthetic oil change doesn’t restore power, it indicates significant internal wear. At this point, you have two choices: rebuild or replace. Rebuild kits are available directly from Tuff Torq and contain the necessary pump, motor, seals, and filter to restore the unit to factory performance.

Rebuilding is a detailed process but is well-documented in online videos and forums. When reassembling the case, ensuring a perfect seal is critical to prevent leaks. This final step is as important as properly caulking a butcher block countertop to protect it from moisture. A complete replacement transaxle is a more expensive but faster option if you’re not comfortable with an internal rebuild.

Quick-Reference Troubleshooting Table

Use this table to quickly diagnose your issue and find a corresponding solution.

| Symptom | Possible Cause | Solution |

|---|---|---|

| Loses power when hot or on hills | Old, broken-down transmission oil | Change oil to full synthetic 5W-50. |

| No movement at all, sudden failure | Broken drive belt or disengaged freewheel lever | Inspect/replace drive belt; check freewheel lever. |

| Loud whining or grinding noise | Low/contaminated fluid or internal damage | Check for leaks; perform an oil change. If noise persists, consider a rebuild. |

| Jerky or hesitant movement | Air in the system or slipping belt | Purge the transmission after an oil change; check belt tension. |

| Mower moves when pushed with freewheel lever in | Internal bypass valve issue | Requires internal inspection/rebuild. |

Proactive Care: How to Make Your L110 Transmission Last

Once your transmission is healthy again, you want to keep it that way. A few simple habits can dramatically extend its life.

The Importance of a Clean Transaxle

Regularly clean all debris from the top of the transmission. Use a leaf blower or compressed air after each mowing session to clear away grass clippings and dirt. This ensures the cooling fan can do its job effectively, preventing the oil from overheating.

Smart Mowing Habits

Avoid using your L110 for tasks it wasn’t designed for. Limit heavy towing and try to mow steep hills in a way that minimizes strain, such as going up and down rather than across. If you have a very hilly property, a tractor with a heavier-duty transmission may be a better long-term choice.

Regular Inspections

Make a habit of visually checking your mower’s undercarriage. A quick look can catch a failing drive belt or a damaged cooling fan before it leads to a bigger problem. It’s a bit like noticing early streaks inside double-pane windows; catching it early prevents a much bigger headache down the road.

Frequently Asked Questions (FAQ)

What kind of oil does a John Deere L110 transmission take?

While it came from the factory with 10W-30 conventional motor oil, the highly recommended replacement and upgrade is a full synthetic 5W-50 motor oil. Tuff Torq, the manufacturer, endorses this for improved performance and durability.

Can I use a thicker oil in my K46 transmission?

Yes, using a thicker synthetic oil like 5W-50 or even 15W-50 is a common and effective strategy. It helps compensate for internal wear by maintaining better hydraulic pressure at high temperatures, which is when the transmission typically starts to feel weak.

How much does it cost to replace a John Deere L110 transmission?

A brand new Tuff Torq K46 transaxle can cost several hundred dollars, often ranging from $700 to over $1,000 for the part alone. A rebuild kit is a more affordable option, typically costing between $300 and $400. Given the cost, attempting an oil change first is always the most economical first step.

Facing transmission problems with your John Deere L110 can be daunting, but it’s not a death sentence for your mower. By systematically diagnosing the symptoms and understanding the root causes, you can take practical steps to solve the problem. For the vast majority of owners, a simple fluid upgrade to synthetic oil is all that’s needed to bring that dependable green machine back to life.