Insulate Underside of Deck: Stop Cold Floors & High Bills Now!

That persistent chill in the room above your deck isn’t just in your imagination. An uninsulated deck is like a giant hole in your home’s thermal envelope, constantly leaking expensive conditioned air and making your living space uncomfortable.

This problem is especially noticeable in rooms with floors directly exposed to the outdoor elements via a raised deck or porch. Addressing this thermal weak point is the key to reclaiming comfort and reducing energy waste.

You'll Learn About

Why Your Uninsulated Deck Is Costing You More Than You Think

The space beneath your deck acts as a direct pathway for heat to escape during the winter and infiltrate your home during the summer. This process, known as thermal bridging, forces your HVAC system to work overtime to maintain a consistent indoor temperature.

The consequences are clear: surprisingly high energy bills and a room that’s always too cold or too hot. Beyond comfort and cost, an uninsulated floor structure is more susceptible to moisture issues and can even put pipes running beneath it at risk of freezing.

The Hidden Dangers of an Exposed Deck Underside

An open and uninsulated deck floor is an invitation for more than just cold air. It creates a sheltered environment that can attract pests like insects and rodents seeking refuge from the elements.

Furthermore, without a proper thermal and moisture barrier, the wooden joists and subfloor are vulnerable to condensation. This trapped moisture can lead to the slow, silent development of mold, mildew, and structural rot, compromising the safety and longevity of your deck.

Choosing Your Weapon: The Best Insulation for Under Your Deck

Selecting the right material is the most critical decision in this project. The unique, semi-exposed environment under a deck demands insulation with high moisture resistance and durability. The wrong choice can trap water, lose its insulating properties, and create a breeding ground for mold.

Closed-cell spray foam and rigid foam panels are overwhelmingly the top choices for this application due to their ability to act as an all-in-one air, vapor, and thermal barrier. They effectively stop heat transfer while resisting the moisture that is inevitably present in an outdoor environment.

| Insulation Type | Approx. R-Value per Inch | Pros | Cons |

|---|---|---|---|

| Closed-Cell Spray Foam | R-6.5 to R-7 | Creates a seamless air and moisture barrier; high R-value; adds structural rigidity. | Requires professional installation; higher cost. |

| XPS Rigid Foam Panels | R-5 | Moisture resistant; high compressive strength; easy for DIY installation. | Seams must be meticulously sealed; lower R-value than spray foam. |

| Polyiso Rigid Foam Panels | R-6 to R-6.5 | Highest R-value per inch for rigid foam; often foil-faced for added radiant barrier. | Can absorb some moisture if not foil-faced; slightly more expensive than XPS. |

| Rockwool/Mineral Wool | R-4 to R-4.3 | Fire and pest resistant; excellent sound dampening; vapor permeable. | Must be protected from bulk water; can be difficult to install overhead. |

Why You Must Avoid Fiberglass Insulation

While common for interior walls, traditional fiberglass batt insulation is a catastrophic choice for the underside of a deck. It acts like a sponge, readily absorbing ambient moisture and any water that might splash up from below.

Once wet, fiberglass loses its insulating R-value and becomes a heavy, sagging mat of mold and mildew. It also provides an ideal nesting material for rodents and insects, turning your solution into a whole new problem.

The Ultimate 7-Step Guide to Insulating Under Your Deck

Proper installation is just as important as material selection. Following these steps ensures you create a durable, effective thermal barrier that will last for years. This guide focuses on using rigid foam panels, the most popular and effective DIY-friendly method.

Step 1: Inspect and Prepare the Joist Bays

Before installing anything, conduct a thorough inspection of the deck’s underside. Look for any signs of water damage, rot, or pest infestation in the joists and subfloor. Make any necessary repairs first; covering up a problem will only make it worse.

Ensure the area is clean and free of debris, cobwebs, and any old, failed insulation. A clean surface is essential for proper sealing later on.

Step 2: Control Bulk Water

Insulation is not a substitute for proper water management. Ensure the deck surface above has proper flashing where it meets the house. Gutters should be clean and directing water away from the foundation and the area below the deck.

Solving any drips or drainage issues is a non-negotiable first step. Sealing the deck floor from below will trap any water that gets in from above, leading to guaranteed rot.

Step 3: Air Seal the Deck Floor

The biggest source of energy loss is often air leakage, not just heat conduction. Before you even think about placing your insulation panels, you must air seal. Use a can of spray foam or durable exterior caulk to seal every single gap and penetration.

Pay close attention to the rim joist (where the deck frame meets the house) and any areas where wiring or plumbing pass through the floor. This step is the secret to professional-level results.

Step 4: Measure and Cut Your Rigid Foam

Measure the distance between your floor joists. These measurements can vary slightly, so measure each bay individually for a snug fit. Subtract about 1/4 inch from your measurement to allow for a small gap on each side, which you will later fill with sealant.

Use a sharp utility knife with a fresh blade and a long straight edge to score the foam panels and snap them cleanly. For thicker panels, a hand saw or foam-cutting blade may be necessary.

Step 5: Install the Foam Panels

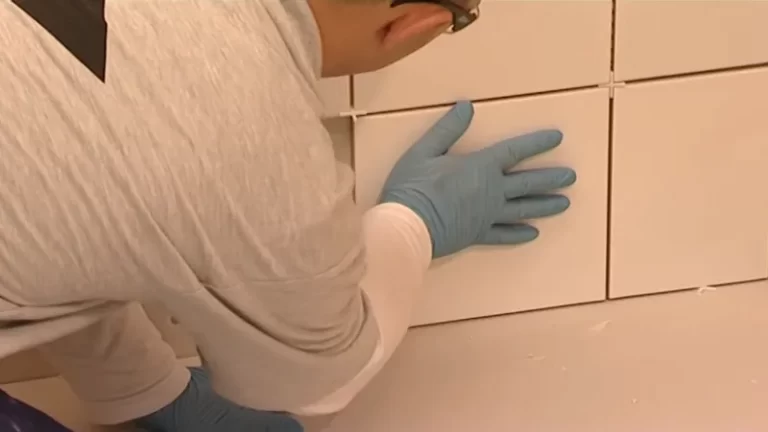

Press the cut foam panels into the joist bays, pushing them up until they are snug against the subfloor above. The goal is to eliminate any air gaps between the insulation and the floor. You can use foam-compatible adhesive on the back of the panels to help hold them in place.

For a truly robust installation, especially in areas with significant temperature swings, consider installing two thinner layers of foam and offsetting the seams. This technique helps to eliminate thermal bridging through the joints.

Step 6: Meticulously Seal All Seams

With the panels in place, use a can of low-expansion spray foam to fill the small gaps you left along the edges of each panel next to the joists. This “picture framing” technique creates a monolithic, airtight seal.

Next, use high-quality flashing tape or house wrap tape to seal all the seams between the foam panels. This ensures a continuous air and vapor barrier across the entire underside of the deck.

Step 7: Add a Protective Underside Covering

While XPS and Polyiso foam are moisture-resistant, they are not indestructible. To protect your investment from physical damage, pests, and UV rays, it’s wise to install a protective covering over the insulation.

Pressure-treated plywood or a dedicated vinyl under-decking system are excellent choices. This final layer provides a clean, finished look and adds a critical layer of defense, ensuring the insulation performs for the life of the deck. Improving airflow and protection is key, much like understanding whether you can put plywood over attic insulation, where the principles of moisture management are equally critical.

Beyond Insulation: Critical Considerations for a Lasting Solution

A successful project goes beyond simply installing foam panels. You must consider the entire system, including moisture dynamics, pest control, and the structural capacity of your deck.

Overlooking these factors can lead to unintended consequences that undermine your hard work. A holistic approach ensures your insulated deck remains healthy and functional.

The Hidden Enemy: Moisture and Ventilation

The single most important factor for success is moisture management. By insulating with a vapor-impermeable material like closed-cell spray foam or foil-faced rigid foam, you are preventing moisture from the outside from being driven into the floor structure.

It is crucial that the floor assembly can dry in at least one direction. Since you are closing it off from below, it must be able to dry to the inside (up into the living space). This is why you should never have a vapor-impermeable flooring like sheet vinyl on the interior floor of the room above.

Pest Prevention: Don’t Build a Critter Condo

Insulation can unfortunately create a cozy home for pests if not installed correctly. The combination of meticulous air sealing and using materials that pests can’t easily burrow through is your best defense.

Rigid foam is generally pest-resistant, but sealing every single gap with spray foam and tape is what truly makes it impenetrable. Adding a solid covering like plywood provides another barrier against curious critters.

Structural Integrity: Is Your Deck Ready?

While insulation itself is lightweight, adding a protective layer of 1/2-inch or 3/4-inch plywood does add significant dead load to the structure. Before beginning, it’s wise to assess the state of your deck’s framing and supports.

Ensure that posts and support beams are sound and properly spaced. Understanding the fundamentals of support, such as correct lally column spacing, can give you insight into the principles of a well-supported structure. This is even more critical if the deck must support heavy items; the engineering required for a hot tub on a rooftop deck, for example, highlights the importance of professional structural assessment for any significant load.

Frequently Asked Questions (FAQs)

What is the best R-value for under a deck?

The ideal R-value depends on your climate zone. However, a good target for under-floor applications is typically R-20 to R-30. You can achieve this by using 4-5 inches of high-quality rigid foam insulation.

Can I insulate under a deck in a very cold climate?

Yes, and it’s especially beneficial in cold climates where heat loss is most severe. In these regions, using a higher R-value and paying meticulous attention to air sealing is absolutely critical to prevent condensation and ice damming issues within the floor structure.

How much does it cost to insulate the underside of a deck?

The cost varies widely based on materials and whether you DIY or hire a professional. A DIY project using rigid foam panels may cost $3-$5 per square foot. Professional installation of closed-cell spray foam is significantly more expensive, often ranging from $7-$10 per square foot or more.

The Final Verdict: Is Insulating Your Deck Worth It?

For any home with a living space above a deck or porch, the answer is a resounding yes. The project pays for itself over time through significant energy savings, but the immediate improvement in home comfort is priceless.

By stopping drafts, warming up cold floors, and protecting your home’s structure from moisture and pests, insulating the underside of your deck is one of the most effective upgrades you can make. It’s a project that enhances both the enjoyment and the value of your home.