Ignition Proving Failure: Is Your Furnace Doomed? (DIY Fixes)

The cold sets in, you hear the familiar click of your thermostat, and you wait for the comforting rush of warm air. Instead, you hear your furnace try to start, maybe a whoosh of gas, and then… silence. A few minutes later, it tries again, and again, before giving up entirely, leaving you in the cold with a blinking error light.

This frustrating cycle is often due to a safety feature called ignition proving failure. It’s your furnace’s way of saying, “I’ve opened the gas valve, but I can’t confirm a flame is actually present, so I’m shutting down to prevent a dangerous gas leak.” While it sounds serious, the cause is often a simple, inexpensive part that you can fix yourself in under 30 minutes.

You'll Learn About

What is Ignition Proving Failure, Really?

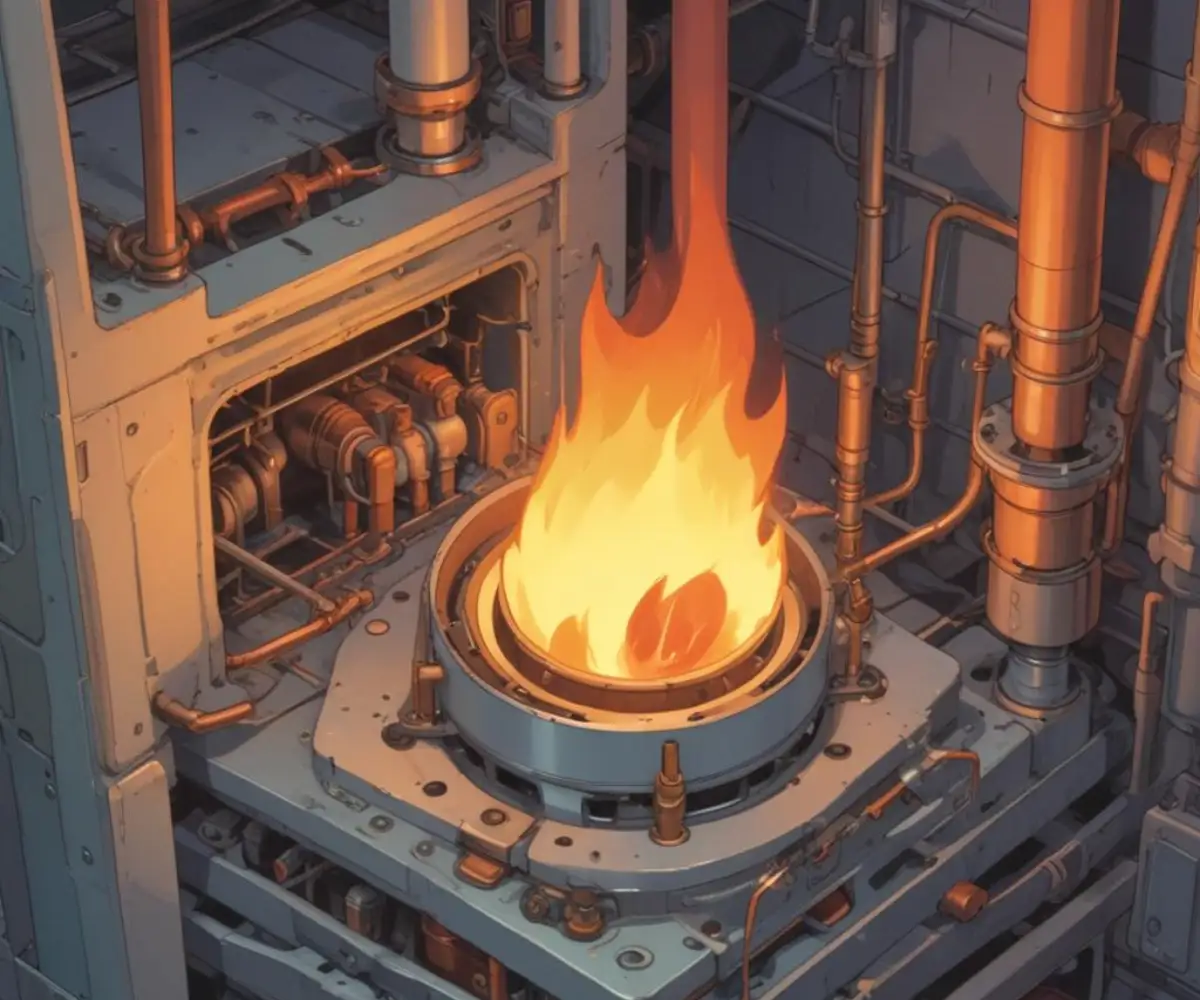

To understand the failure, you first need to understand the successful ignition sequence in a modern gas furnace. It’s a precise, multi-step process that puts safety first. When your thermostat calls for heat, a chain reaction begins inside the unit.

First, the inducer motor kicks on to clear any lingering gases from the combustion chamber. A pressure switch confirms this is done correctly. Next, the igniter—either a hot surface igniter that glows bright orange or a spark igniter—gets activated. Only then does the gas valve open, sending gas to the burners where it’s lit by the igniter. Within seconds, a flame sensor must “prove” a stable flame is present. If it doesn’t send the correct signal back to the main control board, the board immediately shuts the gas valve. This is the “ignition proving failure.”

The Telltale Signs: Symptoms of Ignition Proving Failure

The most common symptom is the furnace attempting to ignite multiple times before going into a “lockout” mode. Typically, you will observe the burners lighting for a few seconds and then abruptly shutting off. This cycle will repeat, usually three times, before the system stops trying altogether to prevent damage or a hazardous buildup of gas.

You might also notice a specific error code flashing from an LED light on the furnace’s control board. You can usually find the meaning of these codes on a sticker inside the main furnace access panel. This code is your most direct clue, often pointing straight to an ignition or flame sensor problem.

Unmasking the Culprits: Top Causes of Ignition Proving Failure

While several issues can trigger this fault, one cause is responsible for the vast majority of cases. Understanding these potential culprits is the first step toward a successful repair, saving you from a costly and unnecessary service call.

1. The Most Common Offender: A Dirty or Faulty Flame Sensor

The flame sensor is a simple yet critical component. It’s a thin, metallic rod, usually bent at the end, that sits directly in the path of the flame from the last burner. Its job isn’t to sense heat, but to conduct a tiny electrical current through the flame itself—a process called flame rectification. The furnace’s control board looks for this specific microamp signal to confirm ignition.

Over time, soot, carbon, and other combustion byproducts can build up on the rod, creating an insulating layer. This layer prevents the sensor from making proper contact with the flame, interrupting the electrical signal. The control board interprets this lack of signal as a lack of flame and shuts the system down, even if the burners are lit perfectly.

2. Weak or Inconsistent Ignition Source

Sometimes, the problem isn’t with proving the flame, but with creating a strong one in the first place. The igniter is a wear-and-tear item. Hot surface igniters can develop hairline cracks that prevent them from reaching the optimal temperature needed for immediate gas ignition.

If the igniter is weak, gas may not light quickly or consistently across all burners. This can result in a delayed or rolling flame that doesn’t properly envelop the flame sensor within the few seconds the control board allows for proof of ignition.

3. Gas Supply and Burner Problems

An improper gas-to-air mixture can also lead to ignition proving failure. If gas pressure is too low, the flame might be too small or unsteady to be reliably detected by the flame sensor. Clogged or dirty burner jets can also be a problem.

If the orifices where the gas exits are partially blocked, it can disrupt the shape and direction of the flame. This can cause the flame to lift off the burner or be turbulent, preventing it from making consistent contact with the flame sensor rod.

4. The Brains of the Operation: Control Board Issues

While less common, the furnace’s main control board can sometimes be the source of the problem. The circuitry responsible for interpreting the flame sensor’s signal can fail. In this scenario, the flame sensor and the flame itself might be perfectly fine, but the board is unable to register the incoming signal correctly.

Diagnosing a bad control board is typically a process of elimination. If you have cleaned or replaced the flame sensor and verified all other components are working, the board itself becomes the primary suspect. This is usually a job for a professional technician.

5. Poor Grounding or Polarity Problems

The flame rectification process relies on a solid electrical ground. The tiny electrical signal flows from the sensor, through the flame, to the grounded burner assembly. If the furnace chassis or the control board has a poor ground connection, this signal can be lost or misinterpreted.

This can be caused by a loose screw, corrosion on a ground wire, or even improper wiring in the house. It’s a more technical issue, but it’s a critical check if you’ve already addressed the more common causes without success.

Your Step-by-Step DIY Troubleshooting and Repair Guide

For the most common cause—a dirty flame sensor—the fix is surprisingly simple. With basic tools and about 15 minutes, you can solve the problem and restore heat to your home. Just remember to always prioritize safety.

Step 1: Safety First! Power Down Your Furnace

Before you open any panels, you must completely cut power to the furnace. Locate the circuit breaker for your furnace in your home’s main electrical panel and switch it off. For added safety, turn off the light-switch-style service switch located on or near the furnace unit itself.

You should also turn off the gas supply. There is usually a shut-off valve on the gas pipe leading to the furnace; turn the handle so it is perpendicular to the pipe.

Step 2: Inspect and Clean the Flame Sensor (The 15-Minute Fix)

Remove the main access panel from your furnace. Look for the burner assembly; the flame sensor is a thin metal rod held in place by a single screw (usually 1/4″ or 5/16″ hex head) and positioned over the last burner in the line. Disconnect the single wire attached to its end and remove the screw.

Gently pull the flame sensor out of its bracket. You will likely see a layer of white or gray buildup on the metal rod. Using a piece of light-grade steel wool or the rough side of a sponge, gently polish the rod until it is shiny and clean. Do not use sandpaper, as it can create grooves that attract future buildup. Wipe the rod with a clean cloth, then carefully reinstall it, reconnect the wire, and replace the furnace panel.

Step 3: Verify Grounding and Electrical Connections

While you have the panel off, take a moment to perform a visual inspection. Look for the main ground wire that connects to the furnace’s metal chassis. Ensure the screw is tight and the connection is free of rust or corrosion.

Also, look at the connections on the control board. Make sure all wiring harnesses are securely plugged in. A loose connection can cause a variety of intermittent problems, including ignition proving failures.

Troubleshooting Ignition Failure: A Quick Reference

Navigating furnace issues can be stressful. This table breaks down common symptoms, their likely causes, and what your next steps should be, whether you’re a DIY enthusiast or know it’s time to call a pro.

| Symptom | Most Likely Cause | Recommended DIY Action | When to Call a Professional |

|---|---|---|---|

| Burners light for 2-3 seconds, then shut off. Repeats 3 times. | Dirty Flame Sensor | Turn off power and gas. Carefully remove and clean the flame sensor rod with light steel wool. | If cleaning the sensor does not resolve the issue. |

| Igniter does not glow, but inducer motor runs. | Faulty Hot Surface Igniter | Visually inspect the igniter for any visible cracks or breaks. | If the igniter is cracked or if you’re not comfortable replacing it yourself. |

| You hear a clicking/sparking sound, but no ignition. | Gas Supply Issue or Dirty Burners | Ensure the gas valve is open. Visually inspect burner jets for soot or blockages. | Immediately if you suspect a gas pressure problem or are not comfortable with burner maintenance. |

| Furnace is completely dead, no sounds or lights. | Power Issue or Blown Fuse | Check your home’s circuit breaker. Check for a fuse on the furnace control board. | If you cannot easily identify the source of the power loss. |

| You’ve cleaned the sensor and checked the igniter, but the problem persists. | Faulty Control Board or Grounding Issue | Check that all ground wires are tight and free of corrosion. | This issue requires advanced diagnostics with a multimeter and professional expertise. |

When to Throw in the Towel: Calling a Professional HVAC Technician

While cleaning a flame sensor is a straightforward DIY task, some furnace repairs are best left to trained professionals. If you’ve cleaned the sensor and the problem continues, it’s time to make the call. Attempting to diagnose a faulty control board or gas valve without proper tools and training can be dangerous.

Never try to adjust gas pressure on your own. This requires specialized equipment and can lead to hazardous situations if done incorrectly. It’s important to know your limits; sometimes the most complex home systems, much like a washing machine drain pipe leaking in the wall, require an expert’s touch to ensure a safe and lasting repair.

Prevention is Better Than a Cure: Maintaining Your Furnace

The best way to deal with an ignition proving failure is to prevent it from happening in the first place. The single most effective step is scheduling an annual professional tune-up. During this service, a technician will clean and inspect all components, including the flame sensor and burners, ensuring they are in optimal condition for the heating season.

Additionally, make sure you change your furnace filter regularly. A clogged filter restricts airflow, which can lead to a host of problems, including overheating and dirtier components. Just as you’d check reviews for chimney repair to find a trustworthy service, investing in quality annual maintenance from a reputable HVAC company is key to your home’s health.

Conclusion: Taking Control of Your Home’s Comfort

An “ignition proving failure” can sound intimidating, but it’s most often your furnace’s safety systems working perfectly to protect you. In many cases, it’s pointing to a simple maintenance issue that you can confidently address yourself. By understanding the role of the flame sensor and how to clean it, you’ve gained valuable knowledge that can save you time, money, and a cold night.

Mastering these small repairs builds confidence and a deeper understanding of how your home works. From the furnace in your basement to choosing the best power tool ecosystem for future projects, every bit of knowledge empowers you as a homeowner. Now, go turn that power back on and enjoy the well-earned warmth.