House Wrap Alternative: Ditch Traditional Methods for These Superior Options!

For decades, rolls of synthetic fabric known as house wrap have been a common sight on construction sites. This material acts as a weather-resistant barrier (WRB), designed to protect a home’s structure from water while allowing moisture vapor to escape. But as building science evolves, so do the materials we use to create durable, energy-efficient homes.

Traditional house wrap, while functional, is not without its problems. Installation errors, such as improper overlapping or failing to tape seams, can create pathways for water and air intrusion. The material can also tear in high winds or degrade from UV exposure if left uncovered for too long, compromising the entire system before the siding is even installed.

You'll Learn About

The Hidden Flaws of Conventional House Wrap

The primary issue with traditional, mechanically fastened house wrap is its susceptibility to human error. Every staple or nail used for attachment creates a penetration point. While these are often small, thousands of them across a building’s exterior can add up, potentially compromising the air and water barrier.

Furthermore, if seams are not perfectly sealed with the correct tape, they can allow significant air leakage, reducing energy efficiency. Taping over dirt, moisture, or in cold temperatures can also lead to poor adhesion, rendering the seal ineffective. These seemingly minor installation details are critical to the performance of the entire wall assembly.

Integrated Sheathing Systems: A Smarter Approach

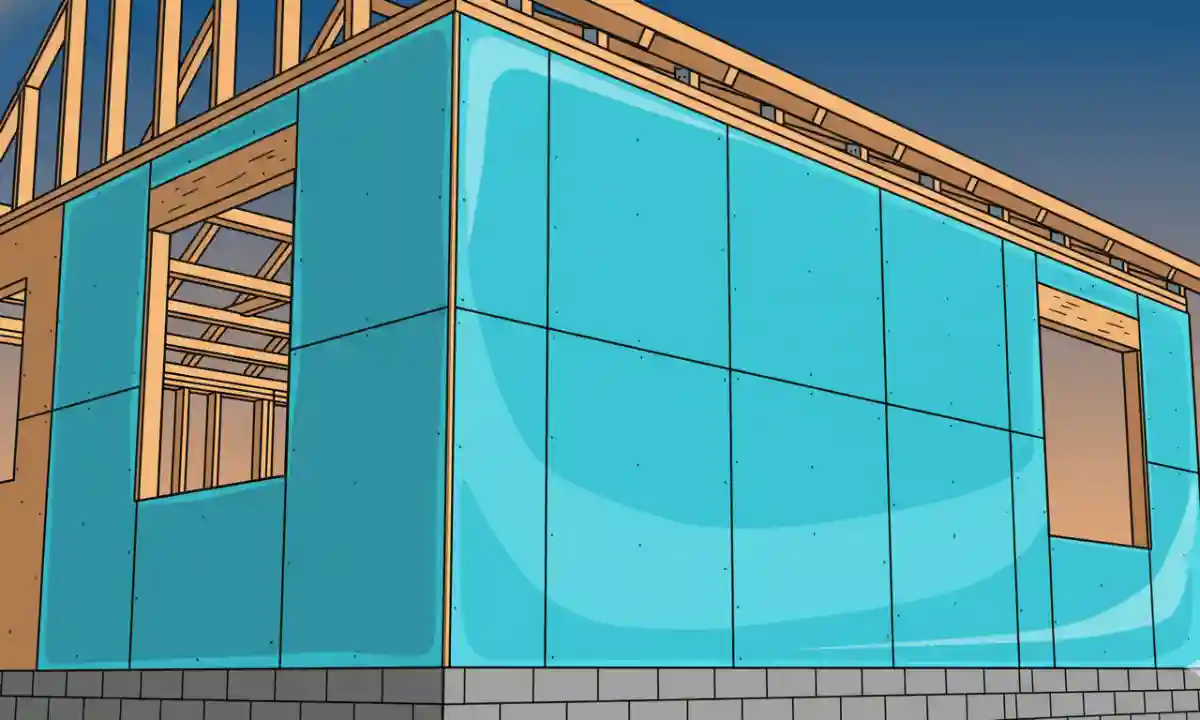

One of the most popular and effective house wrap alternatives is the integrated sheathing system. These products combine structural OSB (Oriented Strand Board) or plywood sheathing with a factory-applied WRB layer. This two-in-one approach eliminates an entire installation step, saving time and labor on the job site.

With integrated systems, the only points that need to be sealed are the seams between the panels. Manufacturers provide high-quality seam tape that creates a continuous, monolithic air and water barrier. This dramatically reduces the chance for installation errors compared to wrapping and taping an entire house. For those weighing their options, understanding the differences in a direct WeatherLogic vs ZIP System comparison can provide valuable insight into which integrated panel is right for a specific project.

Fluid-Applied Weather Barriers: The Seamless Solution

Imagine painting a waterproof, breathable layer directly onto your home’s sheathing. That is the concept behind fluid-applied weather barriers. These liquid membranes are sprayed, rolled, or troweled on, curing to form a seamless, durable, and fully-adhered barrier.

Because they are monolithic and bonded directly to the substrate, fluid-applied systems offer exceptional protection against air and water intrusion. They are particularly effective for complex architectural designs with many corners, curves, and openings where wrapping a traditional fabric would be difficult and prone to errors. This method creates a robust barrier that is fully integrated with the structure.

Rigid Foam Insulation: The Dual-Purpose Barrier

Exterior rigid foam insulation can also serve as a house wrap alternative, offering the significant benefit of adding a continuous layer of insulation. Products like expanded polystyrene (EPS), extruded polystyrene (XPS), and polyisocyanurate (polyiso) can act as a WRB when the seams are properly sealed with manufacturer-approved tape.

Using rigid foam as a WRB improves a home’s thermal performance by reducing thermal bridging through the studs. This method not only protects the sheathing from moisture but also boosts energy efficiency. Properly taping all joints and flashing all openings is absolutely critical for this system to function correctly as a water and air barrier.

A Look at Historical and Niche Options

Before the advent of modern synthetic wraps, builders used materials like asphalt-impregnated building paper or felt. While less common now, these materials are still used in some applications and are often found in older homes. Some historical buildings even used robust materials like asphalt impregnated plywood as a combined sheathing and weather-resistant layer.

These older materials function on the principle of shedding bulk water while having a high capacity to absorb and slowly release moisture. Though newer technologies often provide superior performance, especially regarding air sealing, understanding these traditional methods offers a broader perspective on wall assembly protection.

Comparing House Wrap Alternatives

Choosing the right weather-resistant barrier depends on budget, climate, and the specific design of the home. Each alternative offers a unique balance of cost, performance, and installation requirements. The following table provides a clear comparison to help guide the decision-making process.

| Alternative Type | Installation Complexity | Relative Cost (Material + Labor) | Key Benefit | Best Use Case |

|---|---|---|---|---|

| Integrated Sheathing (e.g., ZIP System) | Low-Moderate | Moderate-High | Speed of installation and reduced seams. | Standard residential construction seeking improved performance over wrap. |

| Fluid-Applied WRB | Moderate-High | High | Creates a seamless, monolithic barrier. | Complex architectural designs and high-performance buildings. |

| Rigid Foam Insulation (as WRB) | Moderate | High | Adds continuous insulation for energy efficiency. | Homes in colder climates focused on maximum thermal performance. |

| Traditional House Wrap (Baseline) | Low | Low | Lowest material cost and wide availability. | Budget-conscious projects where meticulous installation can be guaranteed. |

Frequently Asked Questions

What are common alternatives to traditional house wrap?

Common alternatives to traditional house wrap include other brands of woven or spun polyolefin wraps, rigid foam board insulation, integrated sheathing systems with a built-in weather-resistant barrier, and fluid-applied membranes. Each of these options provides a means of protecting the structure from moisture and air infiltration.

Is rigid foam a good alternative to house wrap?

Yes, rigid foam sheathing can be an effective alternative to house wrap, serving as continuous insulation, a drainage plane, and an air barrier. To function properly as a weather-resistant barrier, the seams of the foam boards must be correctly taped to prevent water and air leaks. While it can be more expensive than traditional house wrap, it offers the added benefit of increased R-value for the wall assembly.

What are integrated weather-resistant barrier (WRB) systems?

Integrated WRB systems, like the ZIP System, combine structural sheathing and the weather-resistant barrier into a single panel. After the panels are installed, the seams are taped to create a continuous air and water barrier, which can save installation time by eliminating the separate step of applying house wrap.

What is a fluid-applied house wrap?

A fluid-applied house wrap is a waterproof membrane that is sprayed or rolled onto the wall sheathing and dries to form a seamless, monolithic weather barrier. This method can provide excellent protection against air and water intrusion by filling small gaps and adhering directly to the substrate, though it is often more expensive than traditional house wraps.

Are there more budget-friendly alternatives to premium house wraps?

Yes, there are several more affordable house wrap brands available that offer comparable performance to industry leaders for less cost. Brands like Barricade and Typar are popular alternatives that provide good moisture protection, durability, and UV resistance, making them suitable for many residential and commercial projects.

Can I use plastic sheeting instead of house wrap?

Using standard plastic sheeting is not recommended as a substitute for house wrap because it does not allow water vapor to escape from within the wall cavity. This can lead to trapped moisture, condensation, and potential issues like mold and rot. Proper house wraps are designed to be breathable, preventing these problems while still resisting bulk water intrusion from the outside.

Making the Right Choice for Your Home

Climate and Vapor Permeability

The ability of a wall to dry out is crucial for its longevity. The “breathability” or vapor permeability of a WRB is a key factor, and the ideal level depends on the climate. In colder climates, a wall needs to be able to dry to the outside, while in hot, humid climates, it often needs to dry to the inside. Modern alternatives offer a range of permeability ratings to suit different climate zones.

Consulting with a local builder or architect who understands regional climate conditions is essential. Choosing a product with the wrong perm rating can trap moisture within the wall assembly, leading to serious issues over time.

The Uncompromising Role of Proper Installation

Regardless of which system you choose, its effectiveness is entirely dependent on proper installation. A high-performance fluid-applied membrane will fail if not applied at the correct thickness, and an integrated sheathing system will leak if the seams are not taped correctly.

Ensure your building contractor is experienced with the specific system being installed. Adhering strictly to the manufacturer’s installation guidelines for flashing around windows, doors, and other penetrations is not just a recommendation—it is a requirement for a durable, weather-tight home.

Conclusion: The Future of Wall Protection

Moving beyond traditional house wrap is about more than just trying something new; it’s about embracing superior building science to create more resilient and energy-efficient homes. Integrated sheathing, fluid-applied membranes, and rigid foam systems offer significant advantages in performance, particularly in creating a continuous air barrier.

While the initial cost may be higher than conventional wrap, the long-term benefits of reduced energy bills, improved indoor comfort, and enhanced protection against moisture damage make these alternatives a worthy investment in the longevity and health of your home.