GoBoard Schluter Hybrid: The Pro Shortcut to a Flawless Shower

You’re standing in the aisle, staring at a wall of tile backer boards. On one side, you have the ultra-lightweight, easy-to-cut Johns Manville GoBoard. On the other, the iconic orange of the Schluter-Kerdi system, a brand synonymous with bulletproof waterproofing. The problem? You love the speed and simplicity of GoBoard, but you trust the comprehensive sealing components of Schluter. This leaves builders and DIYers asking a critical question: Can you combine them for the best of both worlds?

Creating a hybrid system is a common practice among seasoned professionals who want to optimize their workflow, but it comes with its own set of rules and risks. Done correctly, it can save time and money. Done incorrectly, it can lead to catastrophic leaks and failures down the road. This guide will break down exactly how to create a reliable GoBoard Schluter hybrid shower, what potential pitfalls to avoid, and why this “off-label” method has become a go-to for many in the industry.

You'll Learn About

What Exactly is a GoBoard Schluter Hybrid System?

A GoBoard Schluter hybrid installation involves using GoBoard panels as the primary tile substrate on the walls while using Schluter’s waterproofing accessories, like Kerdi-Band, pre-formed corners, and pipe seals, to waterproof the seams and transitions. This approach aims to leverage the main advantages of each system. You get the benefit of GoBoard’s lightweight and dust-free cutting, combined with the trusted, time-tested performance of Schluter’s thin-set embedded sealing components.

The primary reason contractors explore this option often comes down to availability and cost. GoBoard can be more readily available and sometimes less expensive than Kerdi-Board. By combining the two, installers can create a custom solution that fits their budget and project needs without compromising on the critical waterproofing details where Schluter excels.

The Elephant in the Room: What About the Warranty?

This is the most important consideration before you begin. Combining products from different manufacturers will void the system warranties from both Johns Manville and Schluter-Systems. Both companies offer comprehensive warranties, but they are only valid when their respective systems are used exclusively and according to their installation guidelines. By mixing and matching, you are taking on the liability yourself.

This is a trade-off many professional installers are willing to make, confident in their own installation methods. However, for a first-time DIYer or anyone who wants the peace of mind that a manufacturer’s warranty provides, sticking to a single, complete system is the safest path. If you choose to proceed with a hybrid build, you are trusting your own craftsmanship entirely.

The “Unofficial” Pro Method: Installing Schluter Over GoBoard

If you’ve accepted the warranty implications, the process for creating a durable hybrid system is straightforward. It relies on meticulous technique, especially when it comes to sealing the seams and transitions. The key is to treat the GoBoard as a stable, waterproof substrate and apply the Schluter accessories over it using the correct type of mortar.

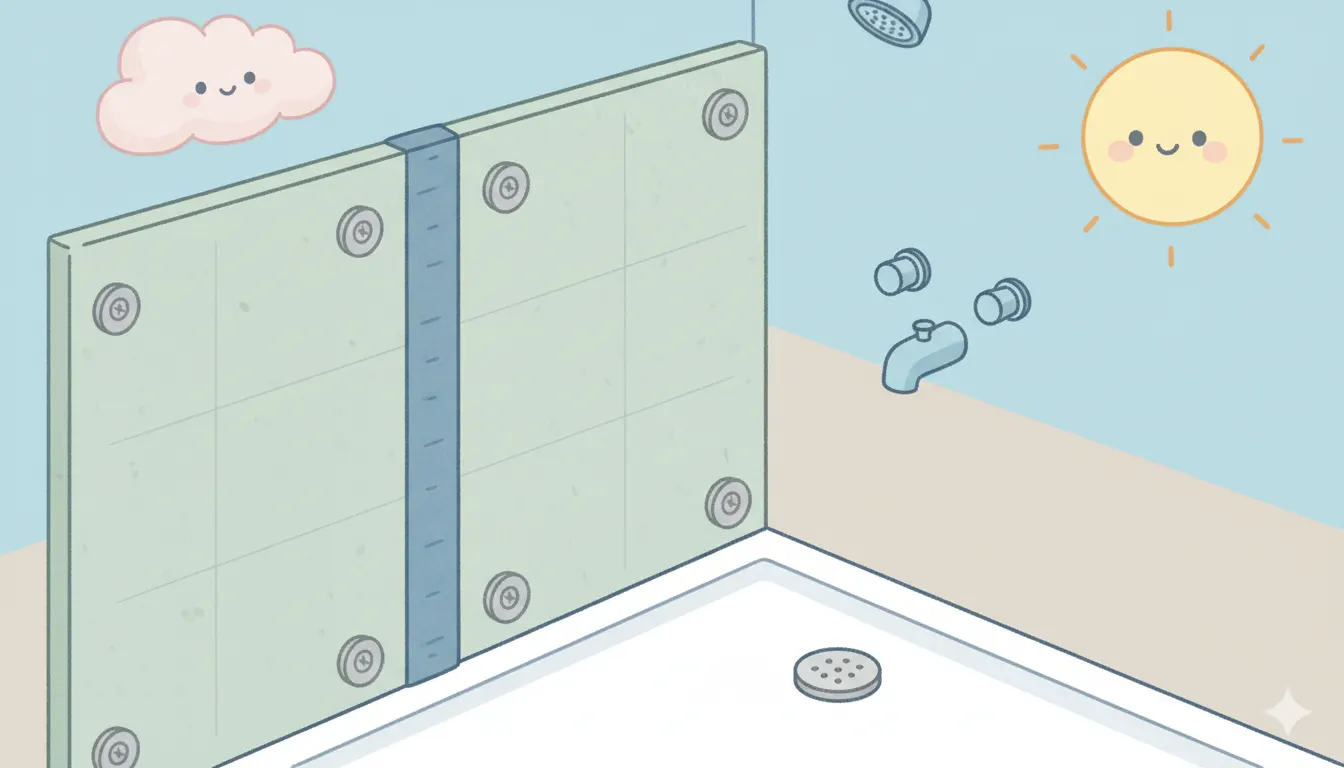

First, install the GoBoard panels directly to the studs according to the manufacturer’s instructions. Ensure the panels are plumb and well-supported, using the specified GoBoard fasteners. Leave a small 1/8″ gap between the boards at the seams. This gap is crucial for the next steps, whether you choose to pre-fill it with sealant or bridge it with Kerdi-Band.

Next, you will waterproof all seams, corners, and fastener locations using Schluter Kerdi-Band. This is the heart of the hybrid method. You must use a high-quality unmodified thin-set mortar to embed the Kerdi-Band. Because GoBoard is a waterproof substrate, a modified thin-set would not be able to dry and cure properly when sandwiched between the board and the Kerdi-Band, which can lead to a weak bond.

Apply a layer of the unmodified thin-set over a seam, press the Kerdi-Band firmly into the mortar with a trowel, and then skim another thin layer over the top to fully encapsulate it. Ensure there are no air bubbles or voids. You will use this same technique for all Schluter pre-formed inside and outside corners, as well as the pipe and mixing valve seals. This creates a continuous, unbroken waterproof layer where it matters most.

GoBoard vs. Schluter Kerdi-Board: A Direct Comparison

To understand why a hybrid system is so appealing, it helps to see how the two core products stack up against each other. Each has distinct advantages that can make it the better choice depending on the specific demands of the project and the preferences of the installer.

| Feature | Johns Manville GoBoard | Schluter Kerdi-Board |

|---|---|---|

| Core Material | Polyisocyanurate (Polyiso) Foam | Extruded Polystyrene (XPS) Foam |

| Weight (1/2″ thick) | Ultra-lightweight, up to 80% lighter than cement board. | Lightweight, but generally slightly heavier than GoBoard. |

| Cutting Method | Scores and snaps easily with a utility knife; virtually dust-free. | Scores and snaps easily with a utility knife; gridlines for easy measuring. |

| Primary Waterproofing Method | GoBoard Pro Sealant applied to seams and fasteners. | Kerdi-Band embedded in thin-set mortar over seams and fasteners. |

| System Warranty | Yes, when used with approved JM products. | Yes, when used exclusively with Schluter system components. |

| Cost | Often more budget-friendly and widely available. | Generally considered a premium-priced product. |

Mortar Selection: The Single Most Critical Decision

The success of your GoBoard Schluter hybrid shower hinges on using the right thin-set mortar. This is a non-negotiable detail where mistakes can lead to total failure. When applying Kerdi membranes over a waterproof substrate like GoBoard, you must use an unmodified thin-set mortar or a specialty mortar like Schluter ALL-SET.

Modified thin-set mortars contain latex polymers that need to air-dry to cure and gain strength. When you sandwich a modified mortar between two waterproof layers (GoBoard and Kerdi-Band), you cut off its access to air, preventing it from curing properly. This can result in a weak, mushy bond that never fully hardens. Unmodified thin-set, on the other hand, cures through a chemical reaction (hydration) and does not need air, making it the perfect choice for this application.

The Hidden Danger: Surface Prep and Bond Breakers

One detail that is rarely discussed but is critical for success is the cleanliness of the GoBoard surface before applying thin-set. The coated surface of GoBoard can collect dust and oils during transport and installation. These contaminants can act as a “bond breaker,” preventing the thin-set mortar from achieving a tenacious grip on the board’s surface.

Before you apply any thin-set for your Kerdi-Band, take a moment to wipe down all the GoBoard surfaces with a clean, damp sponge and let them dry. This simple step removes any potential bond breakers and ensures your mortar achieves the strongest possible adhesion, securing the entire waterproofing assembly for the long term. This is a small detail that makes a huge difference in the durability of the final installation.

When Does a GoBoard Schluter Hybrid Make the Most Sense?

This method isn’t for every person or every project. It’s best suited for installers who are comfortable working without a manufacturer’s warranty and who have a solid understanding of waterproofing principles. A hybrid approach is particularly advantageous when you want the installation speed of GoBoard but are more familiar or comfortable with the thin-set application of Kerdi-Band over sealant.

It can also be a practical solution driven by logistics. For example, if your local supplier stocks GoBoard panels but you have easier access to Schluter’s wide range of waterproofing accessories, a hybrid system allows you to complete the job without waiting for special orders. If you are looking for alternatives, you might also consider comparing other systems, like exploring Red Guard waterproofing vs Kerdi for different approaches.

Conclusion: A Powerful Technique for the Informed Installer

The GoBoard Schluter hybrid shower system is a perfect example of professional field innovation. It combines the lightweight convenience of GoBoard with the trusted sealing power of Schluter accessories to create an efficient, cost-effective, and highly reliable waterproofing assembly. While it requires forgoing the manufacturer’s warranty, the technique is sound when executed with precision and the correct materials.

The keys to success are meticulous seam treatment with Kerdi-Band, the mandatory use of unmodified thin-set mortar, and ensuring the board surfaces are perfectly clean. For the experienced installer or the well-researched DIYer who understands the risks, this hybrid method offers a flexible and powerful alternative to sticking with a single system.