4-Inch Oak Flooring Glue-Down: The Secret to a Flawless Floor?

You’ve selected beautiful 4-inch oak planks, a timeless choice that promises to elevate your home’s interior. But now you face a critical, and often confusing, installation decision that can make or break your entire project. Does 4-inch oak flooring need to be glued down?

Ask three different installers, and you might get three different answers. This conflicting advice leaves homeowners uncertain, fearing a future of squeaky, gapped, or cupped floors. Getting this single detail wrong can turn your dream floor into a long-term source of frustration.

You'll Learn About

Why 4-Inch Flooring Is a Special Case

Understanding the “why” behind the installation method is crucial. Hardwood flooring planks are categorized by their width for a reason, as width directly impacts how the wood behaves after installation. It’s all about dimensional stability.

Narrow strips, typically under 3 inches, are stable enough to be installed with nails or staples alone. Conversely, very wide planks, often 6 inches or more, expand and contract so much with humidity changes that they almost always require a combination of glue and nails, known as a glue-assist, to keep them in place. Four-inch planks sit right in the middle, a transitional width that makes the installation method highly dependent on one key factor: your subfloor.

Your Subfloor Is the Ultimate Deciding Factor

Forget one-size-fits-all answers. The correct installation method for your 4-inch oak is determined entirely by the material it will be installed upon. This is the single most important variable in the equation.

Installing on a Concrete Subfloor

If your home has a concrete slab subfloor, the answer is simple and non-negotiable. You must use a full spread glue-down installation. There is no mechanical way to properly nail the flooring directly to concrete, making adhesive your only professional-grade option.

This process involves troweling a specialized urethane flooring adhesive over a properly prepared subfloor. The concrete must be clean, flat, and, most importantly, dry. A moisture barrier is essential to prevent moisture from the slab from wicking into the wood and causing catastrophic damage like warping and cupping.

Installing on a Plywood or OSB Subfloor

This is where the debate truly begins. With a wood subfloor, you technically have two choices: a traditional nail-down installation or a glue-assist method. While nailing alone might be considered acceptable by some minimum standards, it is not the optimal choice for planks of this width.

Professionals overwhelmingly recommend a glue-assist installation for 4-inch planks over wood subfloors. This technique involves applying a serpentine bead of flooring adhesive to the back of each plank before nailing it into place. This combination provides the ultimate stability, bonding the wood directly to the subfloor to dramatically reduce movement, eliminate squeaks, and create a floor that feels incredibly solid underfoot.

Glue-Assist vs. Nail-Down: A Head-to-Head Comparison

Making an informed choice requires looking at the pros and cons of each method. While a nail-down installation might save a small amount on upfront costs, the long-term benefits of a glue-assist are substantial, making it a worthy investment in your home’s quality and comfort.

| Feature | Nail-Down Only | Glue-Assist Installation |

|---|---|---|

| Long-Term Stability | Good. Relies solely on mechanical fasteners. | Excellent. Adhesive prevents micro-movements. |

| Noise Prevention | Prone to squeaks and creaks over time. | Superior. Eliminates noise by bonding the plank to the subfloor. |

| Gapping & Cupping | More susceptible to seasonal movement. | Highly Resistant. Adhesive restricts the wood’s ability to expand and contract. |

| Upfront Cost | Lower. Saves on the cost of adhesive. | Higher. Requires purchasing specialized flooring adhesive. |

| Feel Underfoot | Standard solid feel. | Premium solid feel. Feels more substantial and integrated with the home’s structure. |

| Repairability | Easier to replace a single board. | More difficult to remove and replace a single damaged board. |

The Hidden Risks of Nailing Alone

Opting to save a few dollars by skipping the adhesive can lead to significant issues down the road. Wood is a natural material that responds to its environment, and wider planks are more reactive than narrow ones. Understanding these risks is key to appreciating the value of a glue-assist.

The Threat of Cupping and Gapping

All wood expands in humid conditions and contracts in dry conditions. Over a 4-inch width, this movement is more pronounced. Nails alone may not provide enough resistance to keep the plank perfectly flat during seasonal humidity swings, leading to “cupping,” where the edges of the board are higher than its center. In dry winter months, the planks can shrink, leading to unsightly gaps between the boards.

The Inevitable Annoyance of Squeaks

Floor squeaks are the number one complaint with hardwood floors. They are caused by tiny movements of the wood against the subfloor or the fasteners. A nail-down-only installation allows for these micro-movements from day one. A glue-assist, however, creates a solid, unified structure, virtually eliminating the potential for squeaks and ensuring a peaceful, quiet floor for decades.

The Professional Glue-Assist Method: A Quick Guide

Achieving a perfect, long-lasting installation is about more than just using glue; it’s about following a precise process. A proper installation is a complete system where every component works together.

Step 1: Subfloor Perfection is Mandatory

The subfloor must be perfectly flat, clean, and dry. Any imperfections will translate through to the finished floor. It’s also critical to let the oak flooring acclimate inside the home for several days so its moisture content can stabilize with the environment.

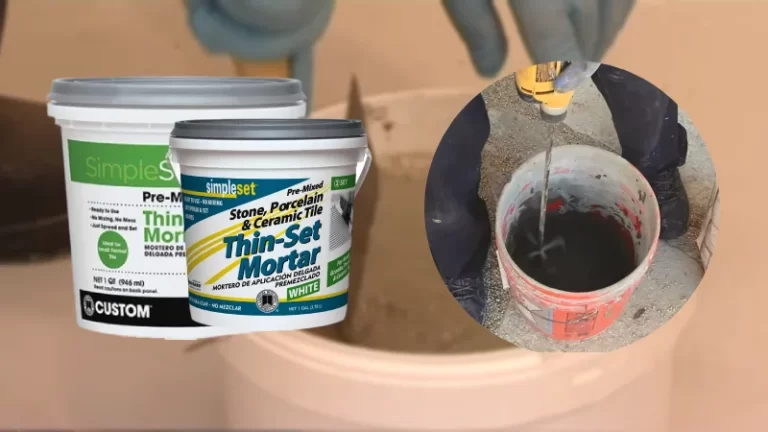

Step 2: Use the Correct Adhesive

Do not use standard construction adhesive. You must use a high-quality, urethane-based flooring adhesive specifically designed for this purpose. These adhesives are elastomeric, meaning they remain flexible to accommodate the natural movement of the wood without breaking their bond.

Step 3: The Serpentine Application

Apply a continuous, 1/4-inch to 3/8-inch bead of the adhesive in a winding “S” pattern along the length of the back of the plank. This ensures coverage across the board’s width, providing the stability needed to control movement.

Step 4: Nailing with Precision

After applying the glue, position the plank and fasten it using a flooring nailer or stapler. Fasteners should be placed every 6-8 inches along the length of the board. This mechanical bond holds the plank securely while the adhesive cures, creating a powerful dual-force installation. The overall stability of the floor is paramount, as issues like plank separation can undermine even the most beautiful materials.

Your Final Questions Answered

Let’s address some final common questions to ensure you have complete confidence in your decision. The nuances of flooring can be complex, but the right information makes the choice clear.

Does solid vs. engineered oak change the answer?

Yes, it can. Engineered oak is constructed in layers, making it more dimensionally stable than solid oak. While a 4-inch engineered plank is less likely to cup, a glue-assist is still highly recommended for a premium, quiet installation over a wood subfloor. Always follow the specific manufacturer’s installation guidelines for your product. Getting familiar with different product lines, such as through reviews of modern flooring options, can provide helpful context.

What if my floor is already nailed down and noisy?

Unfortunately, fixing a squeaky nail-down floor is difficult after the fact. There are some injection-based repair kits, but they have limited success. This underscores the importance of using the glue-assist method from the start to prevent the problem before it ever begins.

The Verdict: Glue is a Smart Investment

So, does 4-inch oak flooring need to be glued? Let’s summarize. If you have a concrete subfloor, a full glue-down is not optional—it is required.

If you have a wood subfloor, while you can get away with nailing it, a glue-assist installation is the superior professional standard. It is your best insurance against squeaks, gaps, and seasonal movement. The small additional cost for adhesive is an investment in the long-term quality, stability, and enjoyment of your beautiful new floors, helping to unlock your home’s true aesthetic potential.

Frequently Asked Questions

Does 4-inch solid oak flooring have to be glued down?

No, it is not an absolute requirement. For 4-inch wide oak flooring, nailing it down is a common and adequate installation method. Generally, a combination of gluing and nailing is recommended for planks that are 5 inches or wider.

What are the advantages of gluing down 4-inch oak flooring?

Gluing down 4-inch oak planks can result in a more solid feel underfoot and can help to minimize squeaking sounds that may occur over time. A full glue-down installation is considered the most permanent method.

Is it acceptable to only nail down 4-inch oak flooring?

Yes, nailing is a standard and acceptable practice for installing 4-inch oak flooring, particularly when it is being installed over a wooden subfloor. This approach is often quicker and more budget-friendly than a full glue-down installation.

What does a “glue-assist” method entail?

The glue-assist method involves applying a serpentine bead of adhesive to the subfloor before nailing down the floorboards. This technique is a compromise that can lead to a quieter floor without the higher cost and complexity of a full adhesive spread.

When is gluing hardwood floors a requirement?

Gluing is the standard method when installing hardwood flooring over a concrete subfloor. For wider planks, typically 5 inches and wider, a combination of glue and nails is recommended to control potential cupping and ensure the stability of the floor.

How does the subfloor material influence the installation method?

The type of subfloor is a critical factor in determining the installation method. With a wooden subfloor, you have the option to nail, glue, or use a combination of both. However, for a concrete subfloor, gluing is the necessary method as nailing is not a viable option.