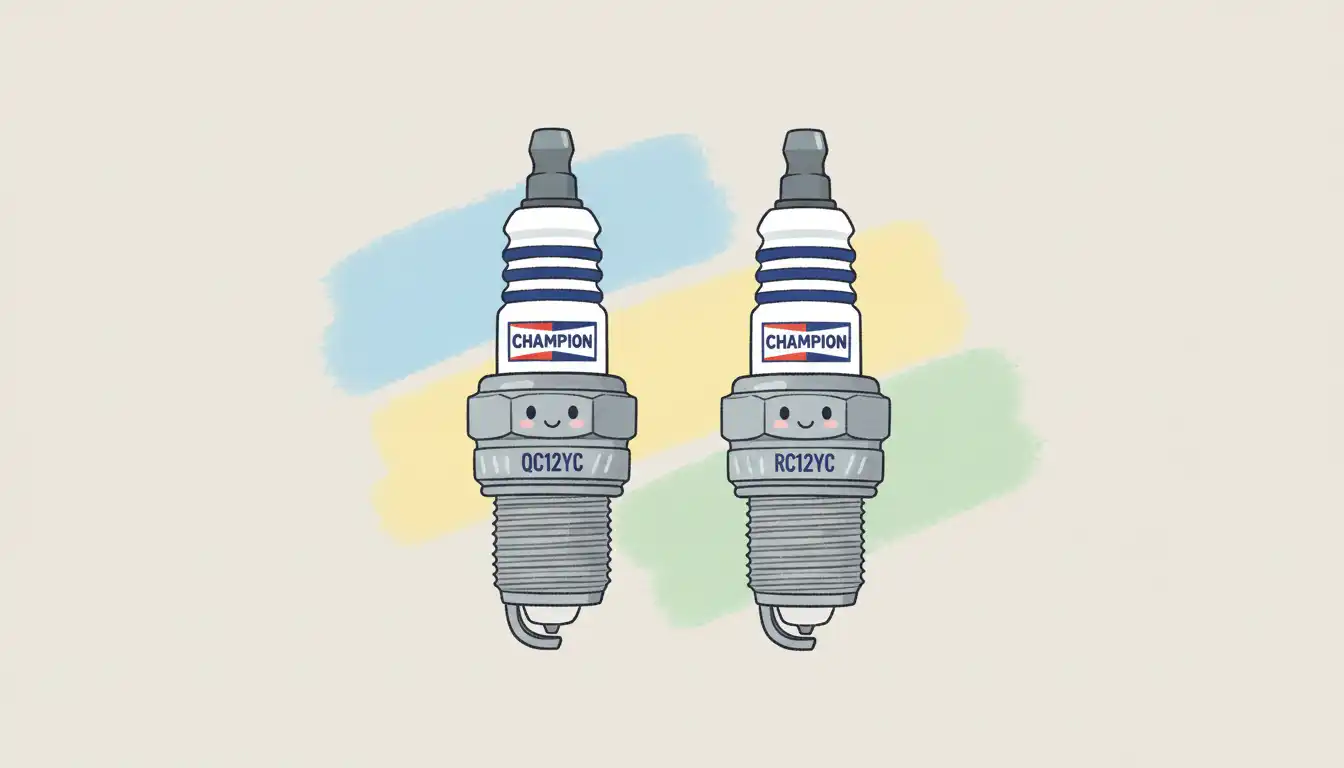

Champion QC12YC vs RC12YC: The Tiny Code Wrecking Your Engine

When it comes to spark plugs, the differences between models can seem minor—just a letter or two in the part number. But those small distinctions can have a big impact on performance, reliability, and safety.

The Champion QC12YC and RC12YC spark plugs may look similar, but they’re engineered for very different environments.

Choosing the wrong one isn’t just a minor oversight—it can lead to serious issues down the line. In this article, we’ll break down the critical differences between these two plugs and explain why selecting the right one for your engine’s specific needs is more than just good maintenance—it’s essential protection for your equipment.

You'll Learn About

The Spark Plug Dilemma: More Than Just a Simple Choice

You stand in the auto parts aisle, two nearly identical spark plugs in hand. One is the Champion QC12YC, the other an RC12YC. They look the same, feel the same, and share most of the same cryptic lettering. It’s a common problem that leads to a dangerous assumption: they must be interchangeable. This moment of confusion is where catastrophic engine problems begin.

Choosing the wrong spark plug isn’t a minor mistake; it’s an invitation for poor performance, electronic interference, and severe, long-term damage. The subtle difference between “QC” and “RC” is a critical distinction that manufacturers expect you to know. One is engineered for a specific, harsh environment, while the other is a general-use component. Making the wrong call can have costly consequences.

Decoding the Champion Formula: What “QC” and “RC” Truly Mean

To solve this puzzle, one must first break the Champion code. The letters and numbers on a spark plug are not random; they are a precise formula describing its construction and purpose. Both the QC12YC and RC12YC share many characteristics, but their prefixes, “Q” and “R,” signify a fundamental difference in their internal components and intended applications.

RC12YC: The Automotive Standard

Let’s break down the common RC12YC. The “R” stands for Resistor. This is a standard feature in most modern spark plugs designed to suppress radio frequency interference (RFI) that could otherwise cause static in your car’s radio. The “C” indicates a 14mm thread, “12” represents the heat range, and “YC” specifies the projected core nose design. This is a robust, reliable spark plug for most automotive and general small engine applications.

QC12YC: The Marine Specialist

Now for the QC12YC. The “Q” in this model number also indicates a suppression element, but it is a specialized Inductive Suppressor. This design is specifically engineered for marine environments, particularly for engines manufactured by Mercury Marine under their Quicksilver brand. While a standard resistor plug handles basic RFI, the inductive suppressor in the “Q” plug is designed to combat a broader and more disruptive range of electromagnetic interference (EMI) common in marine settings.

Head-to-Head Battle: A Direct Specification Comparison

While the plugs appear physically identical, their internal workings and specialized features create a clear divide in their proper use. Understanding these distinctions is key to protecting your engine’s health and performance.

| Feature | Champion QC12YC | Champion RC12YC |

|---|---|---|

| Primary Application | Marine Engines (especially Mercury Marine) | Automotive & General Small Engines |

| Suppressor Type | Inductive Suppressor (‘Q’ Type) | Standard Resistor (‘R’ Type) |

| RFI/EMI Shielding | Superior, for sensitive marine electronics | Standard, for automotive radios |

| Corrosion Resistance | Enhanced for saltwater environments | Standard |

| Core Material | Copper Core | Copper Core |

| Heat Range | 12 | 12 |

| Thread Size & Reach | 14mm x 1.25mm, 19mm reach | 14mm x 1.25mm, 19mm reach |

Beyond the Specs: The Real-World Differences That Matter

The technical specifications on paper only tell part of the story. The true divergence in performance and durability becomes apparent when these plugs are placed in their intended environments. The unique challenges of marine operation demand a specialized component that an automotive plug simply cannot match.

The Marine Environment Menace: Corrosion

Marine engines operate in a world of constant moisture and corrosive salt spray. The Champion QC12YC is specifically built to survive this onslaught. It features superior corrosion resistance in its metal shell and plating to prevent rust and ensure it can be easily removed during maintenance. An automotive-grade RC12YC, when exposed to the same conditions, will corrode much faster. This corrosion not only shortens the plug’s life but can cause it to seize in the aluminum cylinder head, turning a simple tune-up into a costly repair job.

Electronic Warfare: The Critical Role of RFI & EMI Suppression

A modern boat is a hub of sophisticated electronics. GPS, fishfinders, sonar, VHF radios, and digital dashboards all rely on clean electrical signals to function. The spark ignition system is a major source of RFI and EMI, which can disrupt these vital systems. The “Q” inductive suppressor in the QC12YC is far more effective at shielding against this interference than the standard “R” resistor. Using an RC12YC in a marine engine can lead to static-filled radio transmissions, flickering GPS signals, or inaccurate depth readings—major problems when you’re miles from shore. This isn’t about convenience; it’s a matter of operational safety.

Performance and Longevity Under Extreme Load

Unlike a car that experiences variable loads, a boat’s engine often runs at high, sustained RPMs for extended periods. This places immense thermal and physical stress on the spark plugs. The QC12YC is engineered to maintain a stable operating temperature and resist electrode wear under these demanding marine conditions. Using the wrong plug can lead to overheating, pre-ignition, and engine misfires, ultimately reducing power and efficiency. Ignoring this specific engineering is like ignoring a broken truss in an attic; both are seemingly small details that can lead to catastrophic structural failure over time.

The Million-Dollar Question: Can You Swap Them?

This brings us to the most critical point: interchangeability. Given the risks, is it ever acceptable to use one plug in place of the other? The answer requires a clear understanding of the consequences for each specific scenario.

Using an RC12YC in a Marine Engine? A Costly Mistake

Under no circumstances should you use an RC12YC in a marine engine that specifies a QC12YC. The risks are simply too great. You will expose your critical marine electronics to disruptive interference. You will invite rapid corrosion that can damage your engine’s cylinder head. Furthermore, you risk voiding your engine’s warranty, as manufacturers require the use of specified parts. The small amount of money saved on the cheaper plug is insignificant compared to the potential repair bills and safety hazards.

Using a QC12YC in a Car or Lawnmower? Overkill but Generally Safe

Conversely, using the more expensive QC12YC in an automotive or lawnmower engine is less risky, but it is unnecessary and not cost-effective. The physical dimensions and heat range are the same, so it will function. However, the advanced inductive suppressor provides no tangible benefit in a car, which is already equipped to handle the standard RFI from an ‘R’ type plug. It’s a classic case of using the wrong tool for the job. Precision is key in any project, whether you’re learning how to measure a door without removing trim or selecting the right component for an engine. The correct, and more affordable, choice for your car is the RC12YC.

The Broader Picture: Choosing the Right Spark Plug Every Time

The confusion between the QC12YC and RC12YC highlights a universal truth: you must always follow the engine manufacturer’s specifications. Every engine is designed and tested with a specific spark plug type, heat range, and design in mind. Just as choosing between an EGO vs Stihl chainsaw depends on the specific cutting task you have, selecting the right spark plug depends entirely on the engine’s unique operational demands.

Before purchasing a spark plug, always consult your owner’s manual or the manufacturer’s parts lookup guide. Ensure the part number is an exact match or an approved alternative. Properly gapping the new plug and torquing it to the correct specification are just as important as selecting the right part number to begin with.

Frequently Asked Questions

What is the main difference between Champion QC12YC and RC12YC spark plugs?

The primary difference lies in the electrode material. The RC12YC features a copper core electrode, whereas the QC12YC uses a more durable platinum core electrode. Both spark plugs share the same 14mm thread diameter and 3/4″ reach.

Are the QC12YC and RC12YC spark plugs interchangeable?

Yes, they are physically interchangeable as they share the same thread size and reach. However, it is always best to consult your engine manufacturer’s specifications before switching between the two. The QC12YC has an inductive type resistor that may be required for some ignition systems to prevent performance issues.

Which spark plug offers a longer lifespan?

The QC12YC generally has a longer service life. Its platinum core electrode provides better resistance to erosion and fouling compared to the copper core of the RC12YC, resulting in extended durability.

What kind of equipment uses these spark plugs?

Both the QC12YC and RC12YC are designed for small engines. They are commonly used in outdoor power equipment such as lawnmowers, generators, and snowblowers.

Is the more expensive QC12YC worth it?

The QC12YC’s platinum electrode offers a more consistent spark and a longer lifespan, which can mean fewer replacements and better performance in tough conditions. The RC12YC, however, provides reliable performance at a lower price point for general use.

Conclusion: The Clear Winner for Your Engine’s Safety

The battle between the Champion QC12YC and RC12YC isn’t about which plug is “better”—it’s about which plug is correct. For marine applications, the QC12YC is the undisputed winner and the only safe choice. Its superior corrosion resistance and advanced electronic suppression are not luxury features; they are essential for the performance, longevity, and safety of your marine engine and onboard systems.

For automotive and general applications, the RC12YC is the correct, reliable, and cost-effective solution. The “Q” and the “R” are more than just letters; they are a clear guide to an engine’s environment. Heeding this small detail will protect your investment, prevent costly repairs, and ensure your engine performs exactly as its designers intended.

![Taco Zvc404 C Wire [Locating, Connecting, Troubleshooting]](https://fixitinthehome.com/wp-content/uploads/2023/02/Taco-Zvc404-C-Wire-768x432.webp)