Hot Tub Circuit Board Bypass: The Risky Fix You Must Avoid

Your hot tub is cold, the jets are dead, and relaxation feels miles away. In the quest for a quick fix, you stumble upon a tempting suggestion: bypass the hot tub circuit board. It sounds simple, a way to force a pump or heater back to life and get your spa running again.

But this shortcut is fraught with hidden dangers that can lead to catastrophic failure, costly repairs, and serious safety hazards. Before you grab a jumper wire, it is critical to understand what you’re really doing and why a bypass should only be a diagnostic tool, not a solution.

You'll Learn About

What is a Hot Tub Circuit Board? The Brain of Your Spa

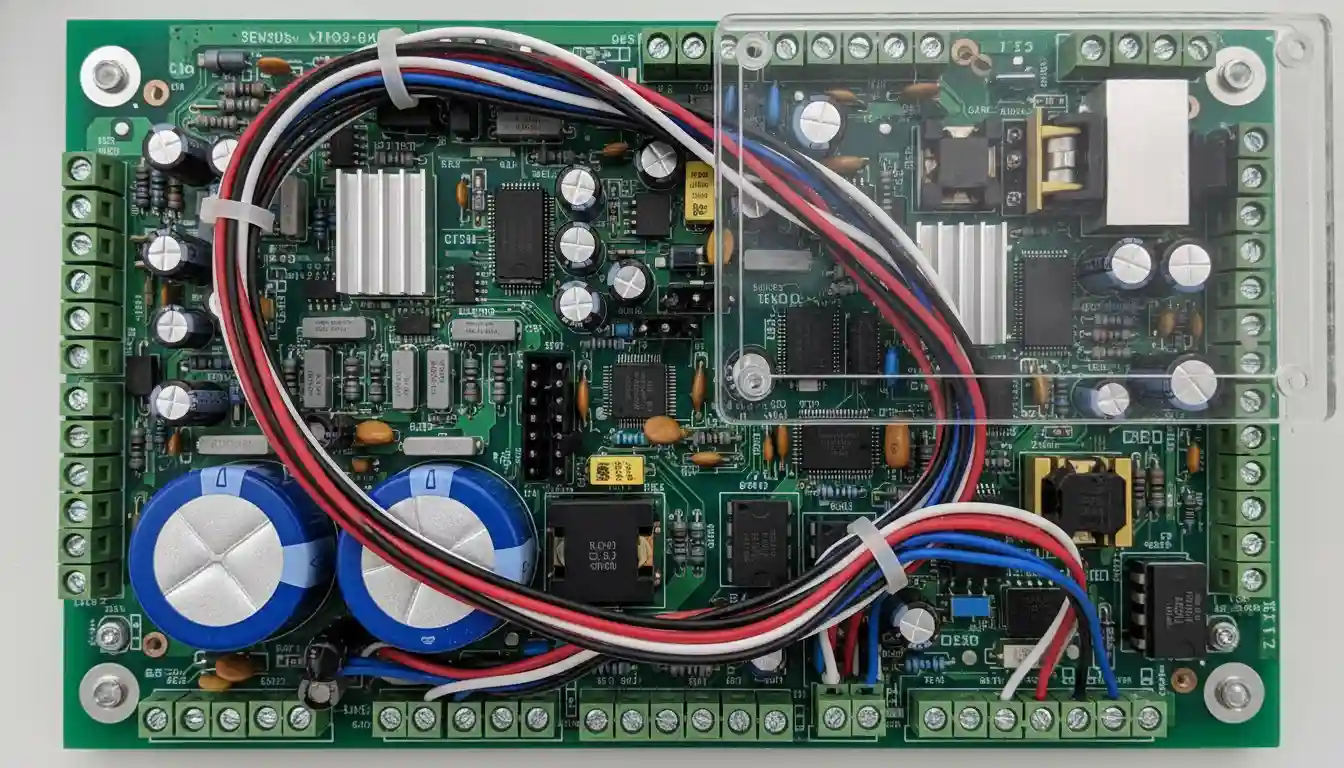

Think of the printed circuit board (PCB) as the central nervous system of your hot tub. This complex grid of wires, relays, and sensors controls every function, from heating the water to running the filtration cycles. It’s the brain that ensures every component works in perfect harmony.

When you press a button on your topside control panel, you send a signal to the board. The board then activates a specific relay—an electrically operated switch—to send power to the corresponding component, like the heater, jets, or lights. This intricate system is designed for both performance and safety.

Why Do Circuit Boards Fail?

Circuit boards can fail for numerous reasons. Moisture from a leak, power surges from a storm, or even damage from insects or rodents can cause components to short out or burn. Over time, relays can simply wear out from repeated use, leading to a component that no longer receives power.

Visible signs of a bad board include scorch marks, melted plastic on relays, or corrosion. Functionally, you might experience unresponsive buttons, erratic behavior where one button activates the wrong component, or a complete loss of power to certain parts of the spa.

Warning: The Hidden Dangers of a Permanent Bypass

A permanent bypass is like disabling the safety features on your car. While you might get from point A to point B, you’re doing so without critical protections. The circuit board does far more than just turn things on and off; it monitors the entire system to prevent disaster.

Hot tub heaters, for example, require a steady flow of water to dissipate the immense heat they generate. If the heater runs without adequate flow—a condition a bypass would allow—it can overheat in seconds. This can melt PVC pipes, destroy the heater assembly, and create a serious fire risk.

The Crucial Safety Features You’re Disabling

When you bypass a circuit board, you eliminate several non-negotiable safety and operational systems. These are not optional features; they are essential for the longevity and safe use of your spa.

Key among these are the high-limit and temperature sensors. These sensors tell the board to shut off the heater if the water temperature exceeds a safe level, preventing scalding. Without them, the water could reach dangerously high temperatures. Similarly, if your hot tub isn’t working correctly, it could be related to issues beyond the circuit board, much like how a problem with your home’s heating might not be the furnace itself but the thermostat on the wall, as sometimes the heat not working on the first floor can be a simple fix.

You also lose freeze protection, where the board automatically circulates warm water to prevent pipes from freezing and cracking in cold climates. Furthermore, you disable programmed filtration cycles, which are vital for keeping your water clean and sanitary. Bypassing these can lead to cloudy, unsafe water, and sometimes you may even notice that your hot water smells like dirt, a sign of underlying plumbing or water quality issues.

The Smart Approach: Using a Bypass for Diagnosis, Not a Fix

While a permanent bypass is dangerous, a temporary one can be an invaluable diagnostic tool. It allows you to isolate a problem with pinpoint accuracy. If a pump isn’t working, is it the pump motor itself that has failed, or is it the relay on the circuit board that’s supposed to power it?

By temporarily and safely bypassing the board’s relay, you can send power directly to the component. If the pump springs to life, you have confirmed that the pump is functional and the problem lies with the circuit board. If it remains dead, you know the pump motor is the culprit and needs replacement. This strategy turns a guessing game into a confident diagnosis.

Essential Tools and Safety First

Before attempting any diagnostic work, safety is paramount. Always turn off the power to the hot tub at the main GFCI breaker. Confirm the power is off with a multimeter. You will need a few basic tools for this test.

Gather an insulated jumper wire (a short piece of 12-gauge electrical wire with alligator clips on both ends is ideal), a multimeter to test for voltage, and insulated gloves. Never perform electrical work in or around standing water. If you are not comfortable working with electricity, do not proceed and call a qualified technician.

Step-by-Step Guide to a Diagnostic Bypass

This process is for identifying a faulty relay for a component like a pump or blower. It is not intended for bypassing a heater, which carries much higher risks.

- Power Off and Access: Ensure the power is disconnected at the breaker. Open the spa’s equipment compartment to access the control box. Carefully remove the cover of the control box to expose the circuit board.

- Identify the Relay: Locate the relay for the non-working component. Circuit boards are often labeled, showing which relay corresponds to “Pump 1,” “Blower,” etc. These are typically small plastic cubes soldered to the board.

- Connect the Jumper: Identify the main power input terminal and the terminal that sends power to the component. Securely connect one end of your jumper wire to the main power line-in terminal. Briefly touch the other end of the jumper to the output terminal for the component you are testing.

- Observe and Conclude: If the component turns on, the relay is faulty. If nothing happens, the component itself (e.g., the pump motor) has failed. Immediately remove the jumper wire after the test. This entire process should only take a second.

Interpreting the Results: What Your Test Reveals

The outcome of your diagnostic bypass points directly to the next step. A successful test (the component turns on) means the circuit board needs repair or replacement. An unsuccessful test means the component is the problem.

Do not be tempted to leave the jumper wire in place as a “fix.” This is extremely dangerous and circumvents all safety protocols. The purpose of this test is only to gather information so you can perform the correct repair.

| Component Tested | Symptom | Bypass Result | Likely Culprit |

|---|---|---|---|

| Main Pump (Low Speed) | No circulation, heating, or filtering | Pump runs when bypassed | Faulty Pump Relay on Circuit Board |

| Main Pump (High Speed) | Jets won’t turn on | Pump runs on high when bypassed | Faulty Jets Relay on Circuit Board |

| Blower | Bubbler system is dead | Blower runs when bypassed | Faulty Blower Relay on Circuit Board |

| Any Component | Component does not respond | Component still does not run | Failed Component (e.g., Pump Motor, Blower) |

The Real Solution: Replacing the Faulty Part

Once you’ve diagnosed the problem, the only safe and reliable solution is to replace the faulty part. Trying to repair a burnt trace or a failed relay on the board itself is possible for those with advanced soldering skills, but for most homeowners, replacing the board is the most practical option.

When ordering a new circuit board, you must match the model number and, critically, the chip revision number. Even boards that look identical may run different software and be incompatible with your topside control panel.

Replacing the Circuit Board

Replacing the board is a methodical process. Start by taking a clear photo of the existing board with all the wires connected. This will be your guide for the new installation. Carefully label each wire before disconnecting it.

Unscrew the old board and mount the new one in its place. Following your photo and the manufacturer’s diagram, reconnect each wire to its corresponding terminal. Ensure every connection is snug and secure, as loose connections can overheat and cause the new board to fail.

Beyond the Board: Other Potential Culprits

Sometimes, the issue isn’t the circuit board or the component but something simpler. Before condemning your board, check for blown fuses on the board itself. A simple fuse replacement might be all that’s needed.

A faulty topside control panel can also mimic circuit board failure. If the display is blank or buttons are unresponsive, the issue could be the panel or the communication cable connecting it to the board. Often, unplugging the topside panel will cause the main pump to start automatically as a default mode, which can help diagnose a bad panel.

Maintaining Your Hot Tub’s Brain for a Longer Life

Preventative maintenance can help extend the life of your circuit board. Keep the equipment area clean and dry. Regularly check for signs of leaks or moisture inside the control box, and address them immediately.

Ensure your spa is protected from major power surges with a properly installed GFCI breaker. Finally, keep pests out of the equipment bay, as they are notorious for chewing on wires and damaging electronic components.

Ultimately, while bypassing a hot tub circuit board can seem like a clever hack, its true value lies only in diagnostics. A permanent bypass is a gamble with safety and equipment longevity that you should never take. Identify the problem correctly, replace the right part, and you can get back to enjoying your hot tub safely for years to come.