Briggs & Stratton Compression Release Repair Cost Revealed!

You grab the pull-cord on your mower, give it a hard yank, and instead of a roaring engine, the cord rips back out of your hand. Or maybe it feels like you’re trying to pull-start a small car; the resistance is just impossible.

If this sounds familiar, you’re likely dealing with a failed automatic compression release (ACR). This small, unseen mechanism is crucial for an easy start, and when it fails, it can bring your yard work to a screeching halt. This guide breaks down the true Briggs and Stratton compression release repair cost, so you can decide whether to tackle it yourself or call in a professional.

You'll Learn About

Why Your Pull-Cord Feels Like It’s Fighting Back: Understanding the Compression Release

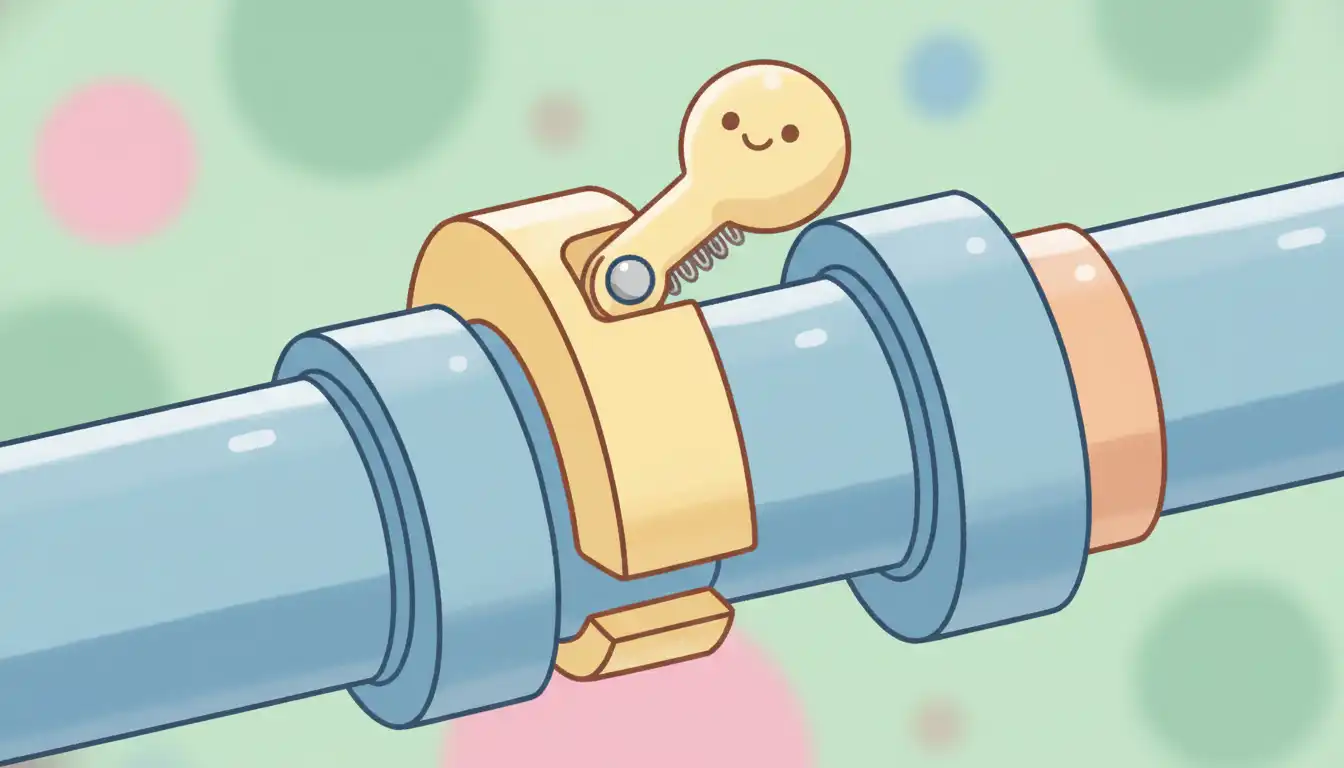

Inside your Briggs & Stratton engine, the automatic compression release is a small, spring-loaded weight on the camshaft. Its only job is to slightly open a valve at very low RPMs—like when you’re pulling the starter cord.

This action releases a tiny amount of compression, making it significantly easier for you to turn the engine over. Once the engine fires up and spins faster, centrifugal force slings the weight outward, disengaging the mechanism and allowing the engine to run with full compression. When this system breaks, you’re left fighting the engine’s full, untamed compression on every single pull.

The Telltale Signs of a Failed ACR

A broken compression release system isn’t subtle. The symptoms are often immediate and hard to ignore, making starting your equipment nearly impossible.

Common signs include a pull cord that is extremely hard to pull, feeling like the engine is seized. You might also experience violent kickback, where the starter rope is forcefully yanked back into the housing. In many cases, an electric starter won’t even have enough torque to overcome the compression, resulting in a clicking sound or a brief, struggling turn.

The Core of the Problem: What Causes the Compression Release to Fail?

Failure of the ACR is almost always a mechanical issue stemming from wear and tear. The small spring can weaken or break, or the pivoting weight mechanism can get stuck or shear off completely.

Crucially, the ACR is an integral part of the engine’s camshaft. This means you can’t just replace the small release mechanism itself; you have to replace the entire camshaft. This turns a seemingly small problem into a significant internal engine repair, dramatically affecting the overall cost and complexity.

Breaking Down the Repair Bill: Professional vs. DIY Costs

When faced with a failed compression release, you have two paths: hiring a professional or tackling the job yourself. The price difference is substantial, primarily due to the intensive labor involved. A professional repair ensures the job is done correctly with the right tools, but it comes at a premium. A DIY repair can save you hundreds, but it’s a complex task that requires mechanical confidence and specialized equipment.

Making the right choice depends on your budget, your mechanical skill set, and how quickly you need your equipment back in service. This table provides a clear comparison to help you weigh the costs and benefits of each approach.

| Item/Service | Professional Repair Cost | DIY Repair Cost | Notes |

|---|---|---|---|

| Parts (Camshaft, Gaskets, Seals) | $80 – $150 | $40 – $100 | OEM parts cost more. Aftermarket kits are cheaper but quality can vary. |

| Labor | $200 – $400+ | $0 | Shops charge $75-$125/hour. This job takes 2-4 hours. |

| Specialty Tools | Included in labor | $50 – $150 | May need a flywheel puller, torque wrench, and feeler gauges. |

| Engine Oil & Supplies | $20 – $30 | $20 – $30 | Fresh oil is required after reassembly. |

| Total Estimated Cost | $300 – $600+ | $110 – $280 | DIY offers significant savings but requires time and skill. |

The Professional Repair Route: Is It Worth the Price?

Taking your equipment to a small engine repair shop is the hassle-free option. Professional mechanics have the experience and specialty tools to perform the camshaft replacement efficiently. Expect labor rates to range from $75 to $125 per hour, with the total job taking between two and four hours.

The total bill, including parts, will likely fall between $300 and $600, depending on your location and the specific engine model. While costly, this price includes peace of mind, a potential warranty on the work, and the assurance that the engine is reassembled and timed correctly.

The DIY Challenge: Are You Ready to Tackle This Repair?

If you’re mechanically inclined, a DIY repair can cut your costs by more than half. The main expense is the replacement camshaft kit, which typically includes the necessary gaskets and seals and costs between $40 and $100 for an OEM part.

However, this is not a simple fix. It requires a deep dive into the engine block. You will need tools like a flywheel puller, a torque wrench for proper reassembly, and feeler gauges to set the valve lash correctly. Understanding engine mechanics is crucial, as incorrect timing during reassembly can lead to catastrophic engine damage. Checking for correct engine pressure is a related skill, and you can learn more about what to expect by understanding the typical Honda GX200 compression PSI, as the principles are similar across small engines.

Step-by-Step DIY Assessment: Before You Buy Parts

Before you start ordering parts, it’s vital to confirm that the compression release is truly the culprit. Other issues can sometimes mimic the symptoms.

First, rule out simpler problems. Check for a fouled spark plug or a clogged air filter. An incorrect valve lash can also cause excessive compression, making the engine hard to start. If you’re comfortable with it, a quick valve adjustment is much easier and cheaper than a camshaft replacement.

To test the ACR, remove the spark plug and the valve cover. Slowly rotate the flywheel by hand and watch the rocker arms. As the piston approaches the top of the compression stroke, you should see the exhaust valve open just slightly—a tiny “bump”—before closing again. If you don’t see this bump, the ACR has failed.

The Hidden Culprit Few Talk About: Oil Sludge and Neglect

One of the most overlooked causes of premature ACR failure is poor maintenance, specifically infrequent oil changes. Engine oil does more than lubricate; it cleans and cools. Over time, old oil breaks down and forms a thick, sticky sludge.

This sludge can restrict the movement of the ACR’s small, spring-loaded mechanism, causing it to stick or fail to engage properly. The constant strain eventually leads to a broken spring or sheared weight. Regular oil changes with high-quality oil are the single best preventative measure you can take to protect not just the ACR, but the entire engine. Proper maintenance is key to longevity for all your outdoor equipment, whether it’s your lawnmower or your Honda 828 snowblower.

Is Repairing Always the Best Option? When to Consider a Replacement Engine

Before investing in a costly repair, take a hard look at the overall condition of your equipment. If your lawnmower or tractor is old, rusty, and showing other signs of wear, sinking several hundred dollars into an engine repair might not be the most economical choice.

As a general rule, if the repair cost exceeds 50% of the value of a new, comparable machine, it’s time to consider a replacement. In some cases, purchasing a new short block (the lower half of the engine) can be a cost-effective middle ground, giving you a fresh start without replacing the entire piece of equipment.

Final Verdict: Pulling the Trigger on Your Briggs & Stratton Repair

A failed compression release can seem like a death sentence for your engine, but it is a repairable issue. The decision to repair it professionally, tackle it yourself, or replace the machine entirely comes down to a balance of cost, skill, and the equipment’s overall condition.

A professional repair will cost between $300 and $600, offering a fast and reliable solution. A DIY repair can be done for under $150-$200 but requires significant time, tools, and technical know-how. By understanding the costs and complexities involved, you can make an informed choice that gets your equipment—and your yard work—back on track. Sometimes, unexpected issues in other areas of the home, like discovering crazing on a fireclay sink, also require a similar cost-benefit analysis.