Bonding a Tankless Water Heater: The Hidden Danger in Your Walls

You’ve upgraded to a new, high-efficiency tankless water heater, looking forward to endless hot water and lower energy bills. However, a critical safety step is often overlooked during installation, one that could turn your entire plumbing system into an invisible hazard. This step is electrical bonding, and misunderstanding its importance can lead to devastating consequences.

Many homeowners confuse bonding with grounding, but they serve different, equally vital roles in your home’s safety. Neglecting to properly bond your tankless water heater can create a risk of electric shock, accelerate pipe corrosion, and even damage the sensitive electronics within the unit itself. It’s a silent threat that exists out of sight but poses a very real danger.

You'll Learn About

What is Electrical Bonding and Why Does Your Tankless Heater Need It?

In the simplest terms, electrical bonding is the process of connecting all metallic components that are not meant to carry a current, like your water and gas pipes, together with a conductive wire. The goal is to ensure all these parts are at the same electrical potential. By tying them together, you eliminate dangerous voltage differences that could occur between two separate metal objects during an electrical fault.

This is different from grounding, which connects your electrical system to the earth to provide a path for fault current to flow, tripping a circuit breaker. Bonding works in tandem with grounding to protect you. A tankless water heater, which combines high-power electricity with water and an extensive network of metal pipes, creates a perfect storm for electrical hazards if not properly bonded.

The Shocking Truth: How an Unbonded Heater Becomes a Hazard

When a tankless water heater is not bonded, it leaves your home vulnerable to several hidden dangers. These issues go beyond just the unit itself and can affect your entire plumbing and electrical system, creating risks that you might not be aware of until it’s too late.

The Stray Voltage Menace

Imagine a wire inside your powerful tankless heater becomes frayed and touches the metal casing. Without bonding, this “stray voltage” energizes the heater’s metal housing. Because the heater is connected to your water pipes, this electrical charge now has a pathway throughout your entire home.

Every metal faucet, showerhead, and spigot becomes a potential source of electric shock. Simply turning on the tap to wash your hands could result in a serious or even fatal injury. Proper bonding provides a safe path for this stray current to travel, allowing it to be discharged safely and trip the circuit breaker as intended.

Galvanic Corrosion and Pipe Damage

A less discussed but equally serious risk of improper bonding is galvanic corrosion. When dissimilar metals, like copper water pipes and steel fittings, are connected within a plumbing system, they can create a small electrical current, especially in the presence of water. This process causes one of the metals to corrode at an accelerated rate, leading to pinhole leaks, joint failures, and costly water damage over time.

Electrical bonding neutralizes this effect by equalizing the electrical potential between all connected metal parts. This stops the destructive electrochemical reaction in its tracks, preserving the integrity of your plumbing and preventing premature pipe failure. It’s a small step that protects a massive investment.

Protecting Your Electronics (and Your Investment)

Modern tankless water heaters are sophisticated appliances with sensitive electronic circuit boards that control temperature, flow rate, and safety features. These components are susceptible to damage from electrical surges and stray voltage. An unbonded system creates an unstable electrical environment where these sensitive parts can be easily fried.

By creating a stable, equipotential plane, bonding helps shield the heater’s internal electronics from electrical anomalies. This protects your investment, prevents costly repair bills, and ensures your unit operates reliably for years to come. This is especially critical if you are considering a major home project like needing to extend a gas line for a stove, as all metal piping systems must be considered together for total home safety.

Bonding vs. Grounding: Clearing Up the Lethal Confusion

Understanding the distinction between bonding and grounding is critical for home safety. While they both contribute to your electrical system’s safety, they are not interchangeable. Confusing the two can lead to a dangerously false sense of security.

Grounding provides a path for electricity to return to the earth during a fault, while bonding ensures all metallic parts are at the same electrical potential to prevent shock. Think of it this way: grounding is about protecting the system, while bonding is about protecting the people who touch it. Both are required by the National Electrical Code (NEC) for a safe installation.

| Feature | Bonding | Grounding |

|---|---|---|

| Purpose | To create an equipotential plane, ensuring no voltage difference between metal parts. | To provide a low-resistance path for fault current to return to the earth. |

| How it Works | Connects all non-current-carrying metal parts (pipes, casing) together. | Connects the electrical system’s neutral point to a grounding electrode (e.g., a ground rod). |

| Primary Goal | Prevents electric shock to people by eliminating touch potential. | Allows overcurrent devices (breakers, fuses) to operate quickly during a fault. |

| NEC Reference | Primarily covered in NEC Article 250, Part V. | Primarily covered in NEC Article 250, Part III. |

Step-by-Step Guide: How to Properly Bond Your Tankless Water Heater

Disclaimer: This information is for educational purposes only. Due to the serious safety implications, bonding should be performed by a licensed and qualified electrician who is familiar with local codes and the National Electrical Code.

Tools and Materials You’ll Need

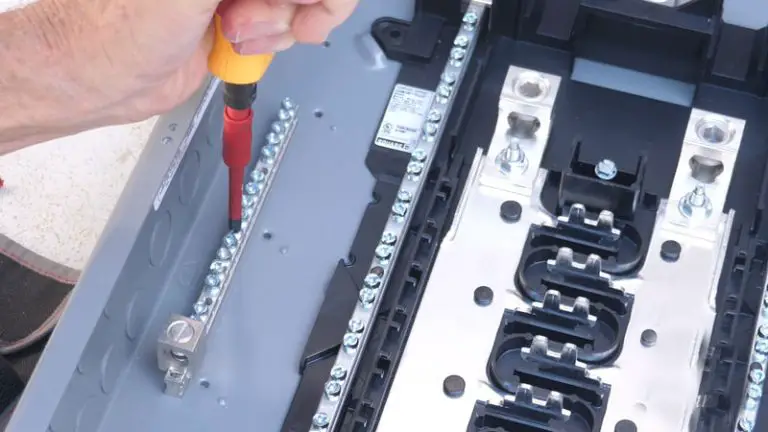

A professional will use specific tools for this job. These typically include a solid copper wire (usually #6 AWG, but local codes may vary), UL-listed pipe clamps designed for grounding and bonding, a wire stripper, and appropriate wrenches or screwdrivers to ensure secure connections.

Identifying the Key Connection Points

Proper bonding requires connecting several key points to create a continuous electrical path. These points are the cold water inlet pipe, the hot water outlet pipe, and the gas line (for gas-fired models). The bonding wire connects these pipes together and then runs back to the main electrical panel’s grounding bus bar, creating a unified connection with the home’s grounding electrode system.

The Bonding Jumper Installation Process

A professional electrician will follow a strict safety protocol. First, they will shut off all power to the water heater at the circuit breaker. They will then scrape any paint or corrosion off the metal pipes at the connection points to ensure excellent metal-to-metal contact. The bonding clamps are then securely attached to the hot and cold water pipes and the gas line.

A solid copper “jumper” wire is installed between these clamps. Finally, a continuous bonding wire is run from one of the clamps directly to the grounding bus bar in the main service panel. This final connection is what ties the entire plumbing system safely to the earth ground.

Special Considerations for PEX and CSST Piping

The use of modern piping materials adds complexity to bonding. PEX (cross-linked polyethylene) is a plastic and does not conduct electricity, which means it can interrupt the electrical path. When PEX is used, bonding jumpers must be installed across the plastic tubing to connect the metal sections of pipe, ensuring continuity. Typically, this is done by bonding the metal fittings where the PEX connects to the heater and the rest of the home’s metal plumbing.

CSST (Corrugated Stainless Steel Tubing), often used for gas lines, presents a unique and serious hazard. Its thin walls can be perforated by arcing electricity during a nearby lightning strike, causing a gas leak and a severe fire risk. For this reason, CSST has its own specific bonding requirements mandated by manufacturers and the National Fuel Gas Code, which involves a direct bond from a rigid pipe fitting to the electrical service grounding system.

Common Mistakes in Tankless Heater Bonding (And How to Avoid Them)

Even with good intentions, mistakes in bonding can render the entire safety system useless. Knowing these common errors can help you ensure the job is done right, whether you are inspecting a professional’s work or simply trying to be an informed homeowner.

Using the Wrong Wire or Clamps

A frequent mistake is using the wrong materials. The National Electrical Code requires a solid copper conductor of a specific size (gauge) for bonding. Using stranded wire or an undersized wire is a code violation and unsafe. Additionally, the clamps used must be specifically listed for grounding and bonding to ensure a permanent and reliable connection.

Ignoring the Gas Line

For gas-powered tankless heaters, bonding the gas line is just as critical as bonding the water lines. An unbonded gas pipe can become energized during an electrical fault, creating an ignition source for a gas leak. This is a recipe for disaster. Both the water and gas systems must be bonded together to equalize their electrical potential.

Connecting to a Water Pipe Downstream from a Plastic Meter

Many homes now have plastic water meters or main shut-off valves installed by the utility company. These non-metallic components can completely isolate your home’s plumbing from the external ground provided by the municipal water main. This makes the internal bonding jumper at your water heater and the connection back to your electrical panel’s ground rods even more critical for safety. In such cases, the metal water pipes are no longer a reliable grounding electrode.

A Loose Connection Can Be a Deadly Connection

The effectiveness of a bonding wire depends entirely on its connections. A clamp that is not tightened sufficiently or is attached to a painted or corroded pipe will not provide a reliable path for electricity. This can lead to arcing or intermittent contact, which is just as dangerous as having no bond at all. Sometimes, what seems like a simple connection can be deceptively tricky, much like when a collet connector is stuck and refusing to budge; the integrity of the connection is everything.

When to Call a Professional Electrician

While the concept of bonding may seem straightforward, its execution is a job for a professional. The risks associated with incorrect electrical work are too high for a DIY project. An issue as seemingly minor as seeing your paint melting off a wall could be a sign of a much deeper electrical problem that requires expert diagnosis.

You should always call a licensed electrician if you are uncertain about your home’s electrical panel, have older wiring, or have any doubts about the proper procedure. A professional will not only ensure the work is done safely but will also make sure it complies with all local building codes, preventing issues with home inspections or insurance claims down the road.

A Final Word

Properly bonding your tankless water heater is not an optional upgrade; it is a fundamental safety requirement. This crucial step protects your family from electric shock, your plumbing from corrosion, and your appliance from electronic damage.

It ensures that all the metallic systems in your home are at an equal electrical potential, transforming them from a potential hazard into a unified, safe network. Don’t leave your home’s safety to chance. Inspect your installation and consult a qualified electrician to ensure your tankless water heater is correctly and safely bonded.